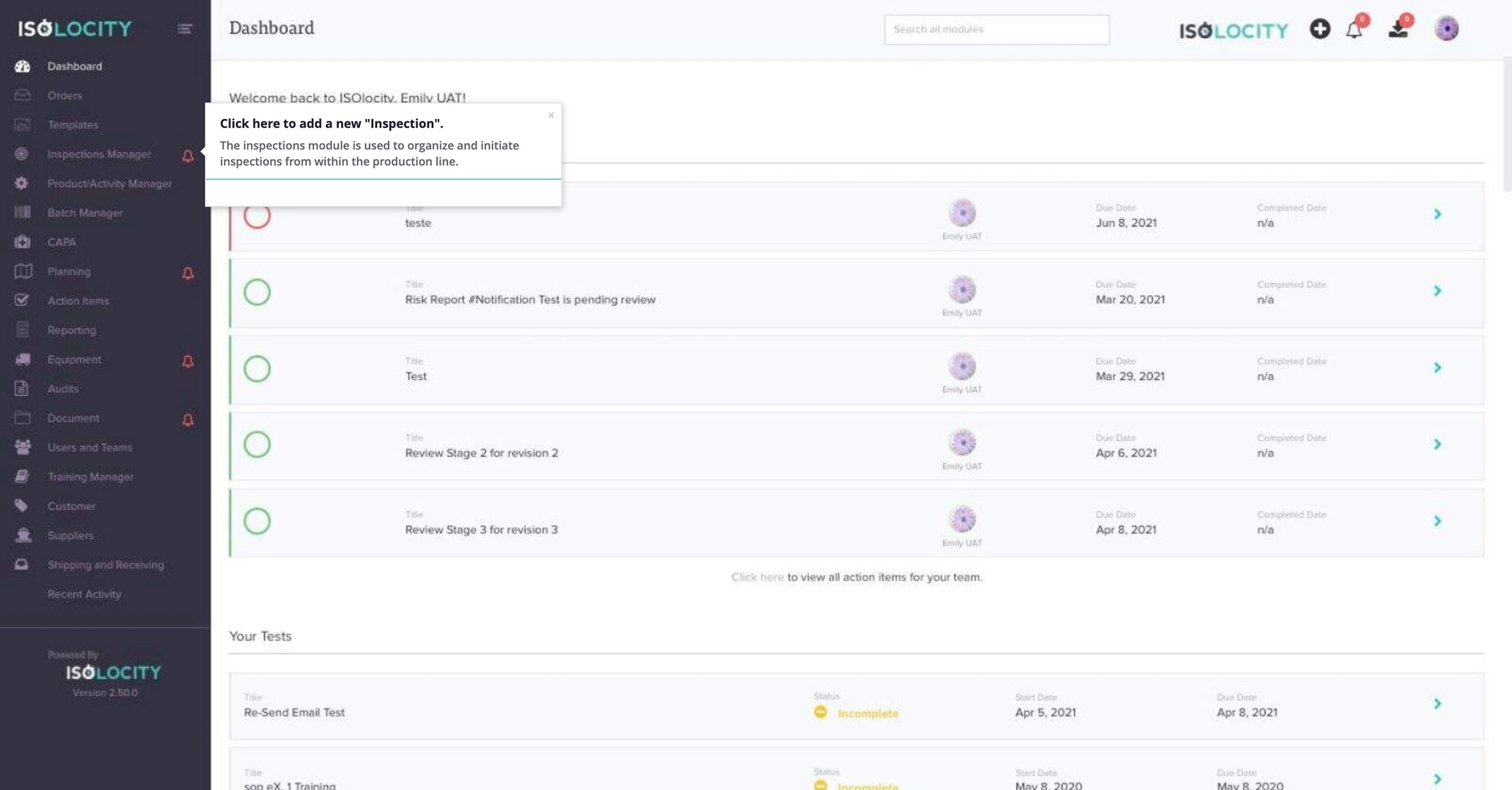

Adding A New Inspection

Step #1

Click here to add a new “Inspection”.

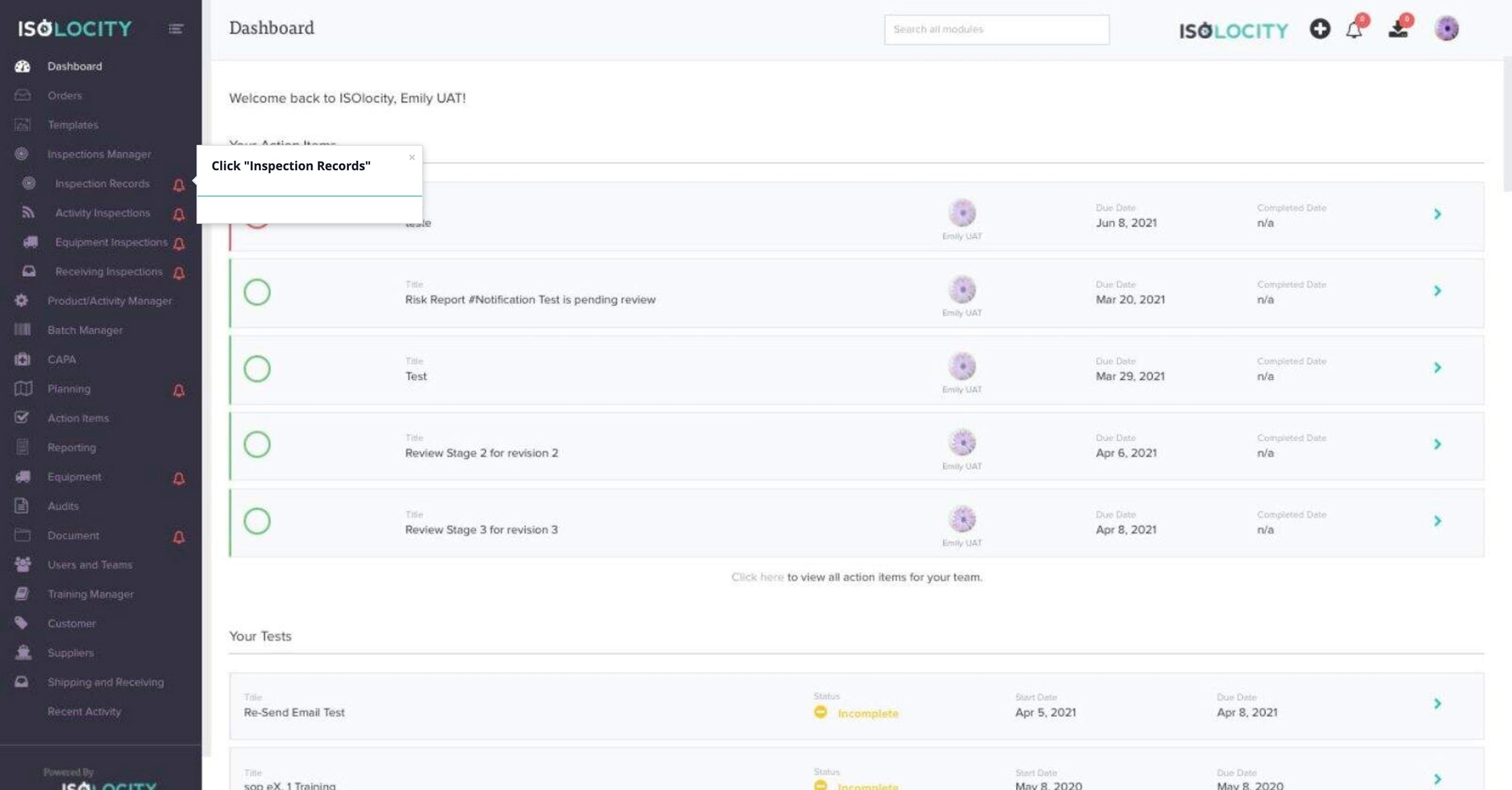

Step #2

Click “Inspection Records”

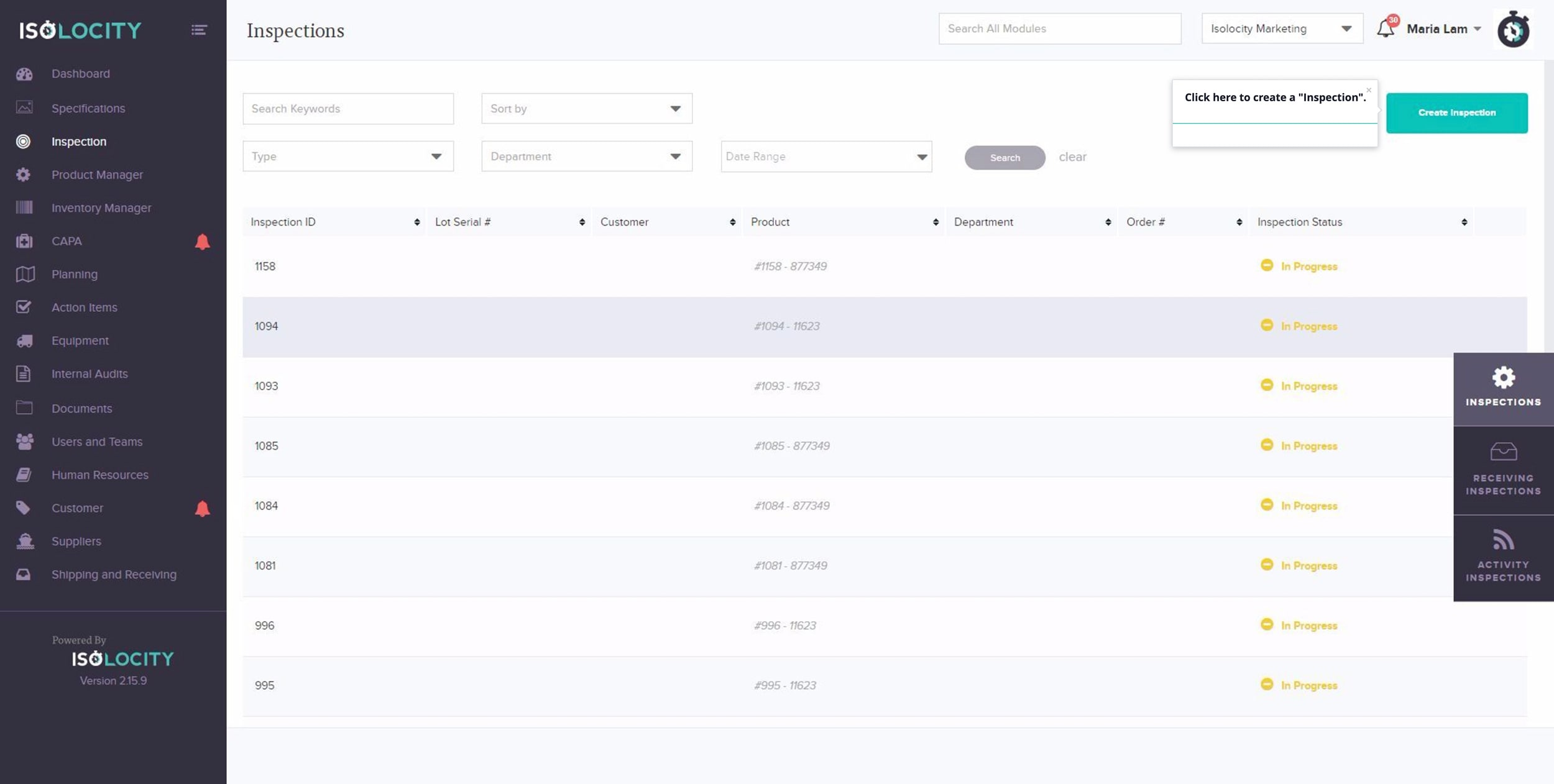

Step #3

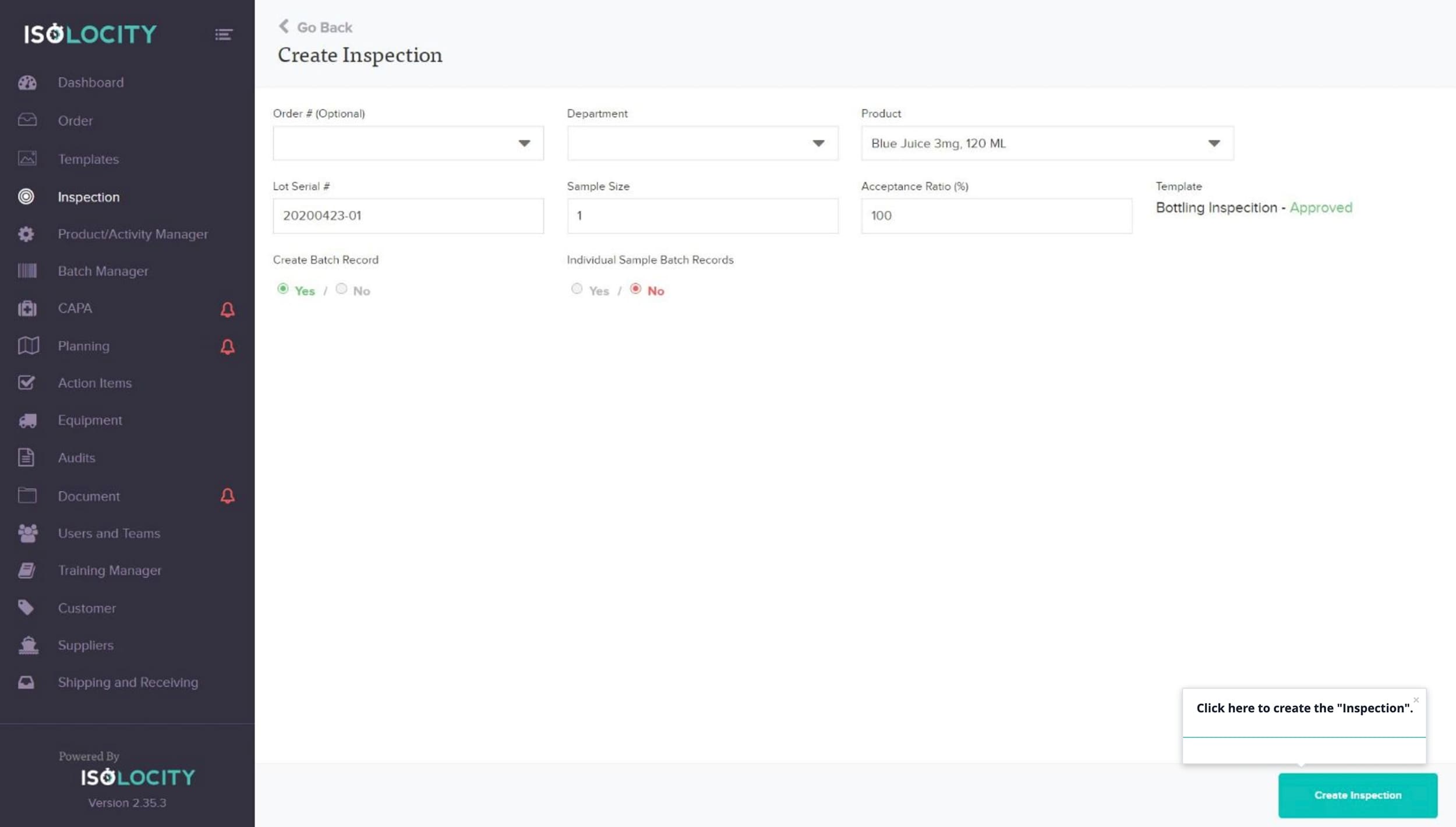

Click here to create a “Inspection”.

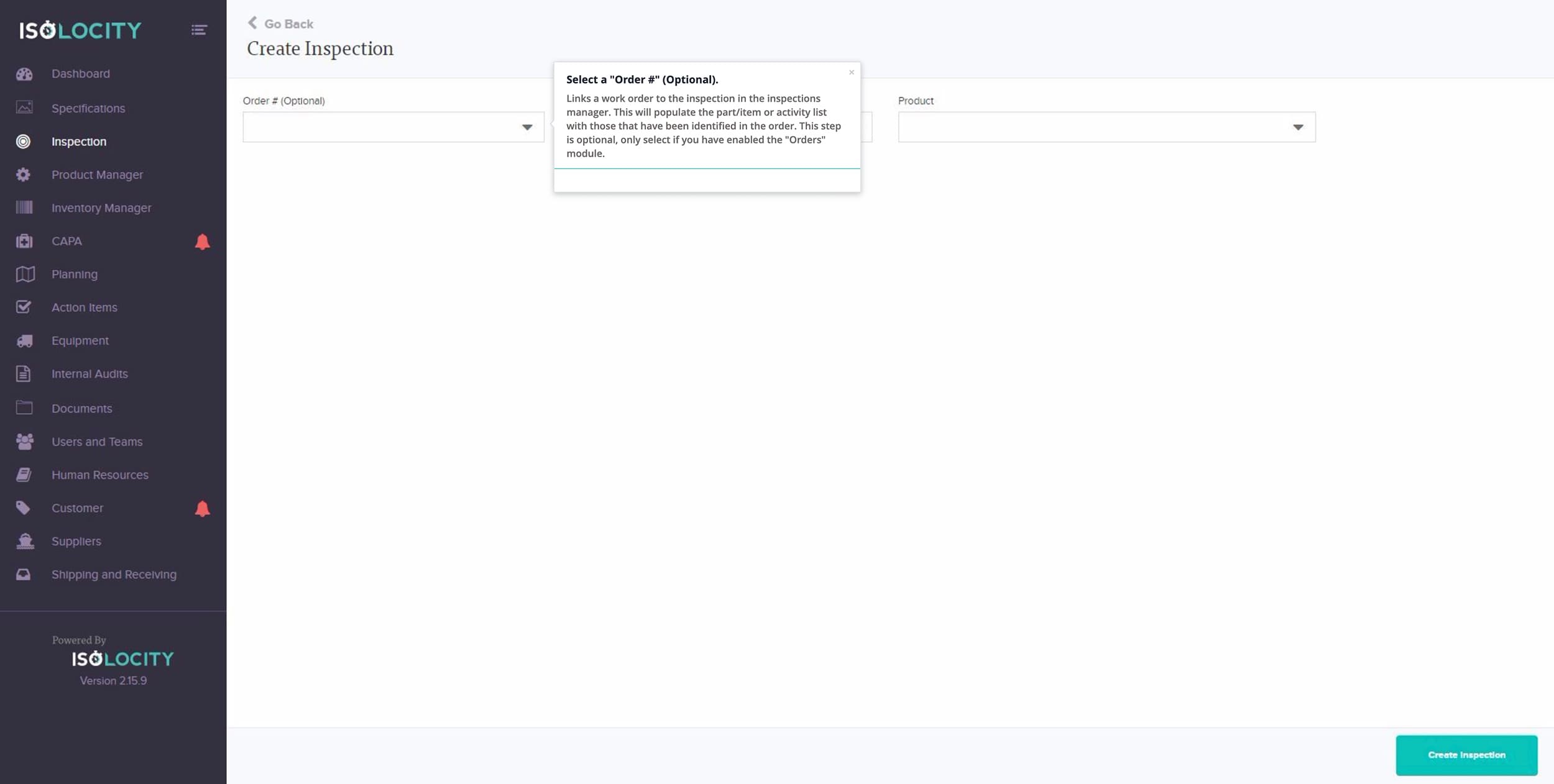

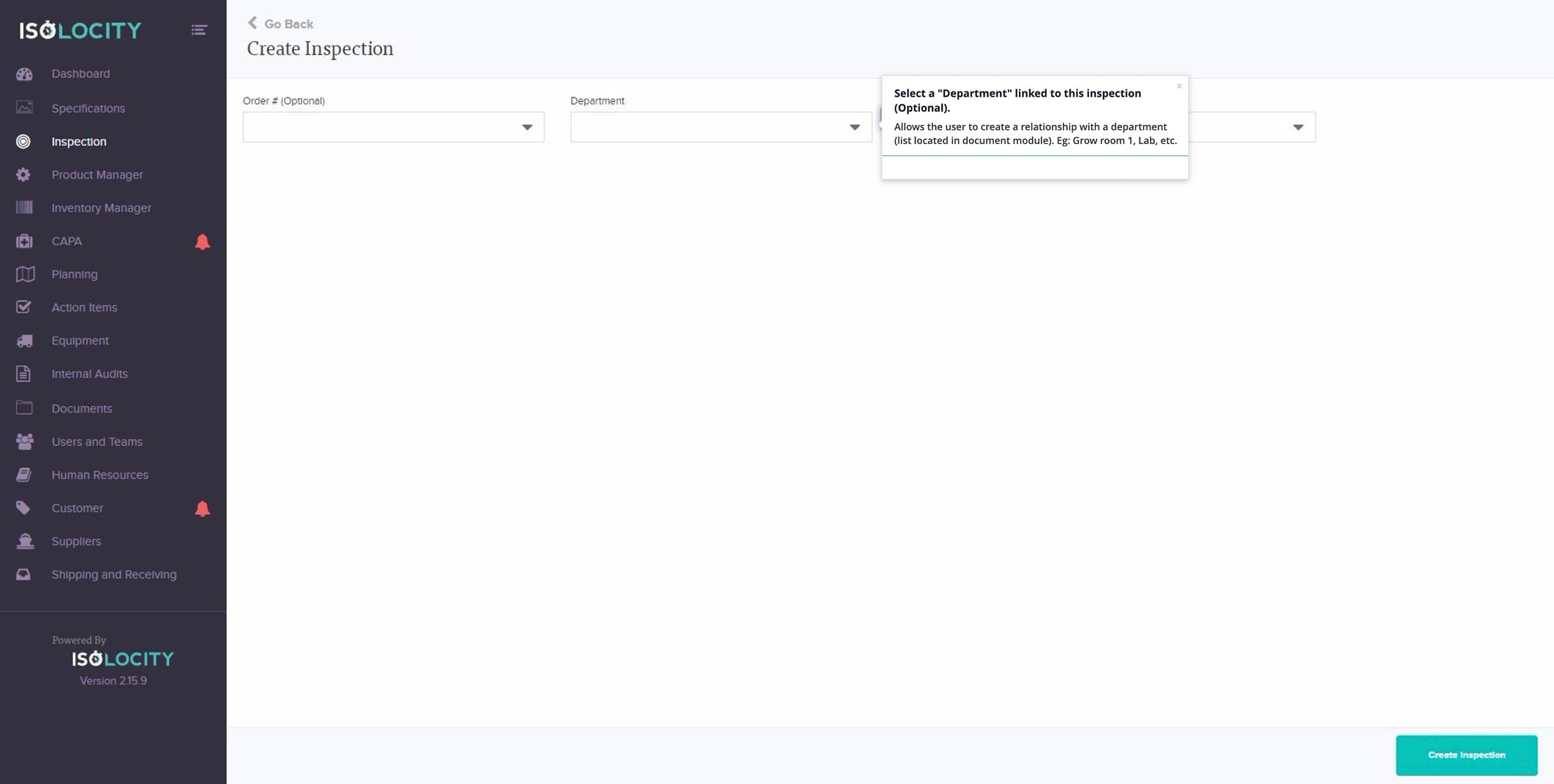

Step #4

Select a “Order #” (Optional).

Step #5

Select a “Department” linked to this inspection (Optional).

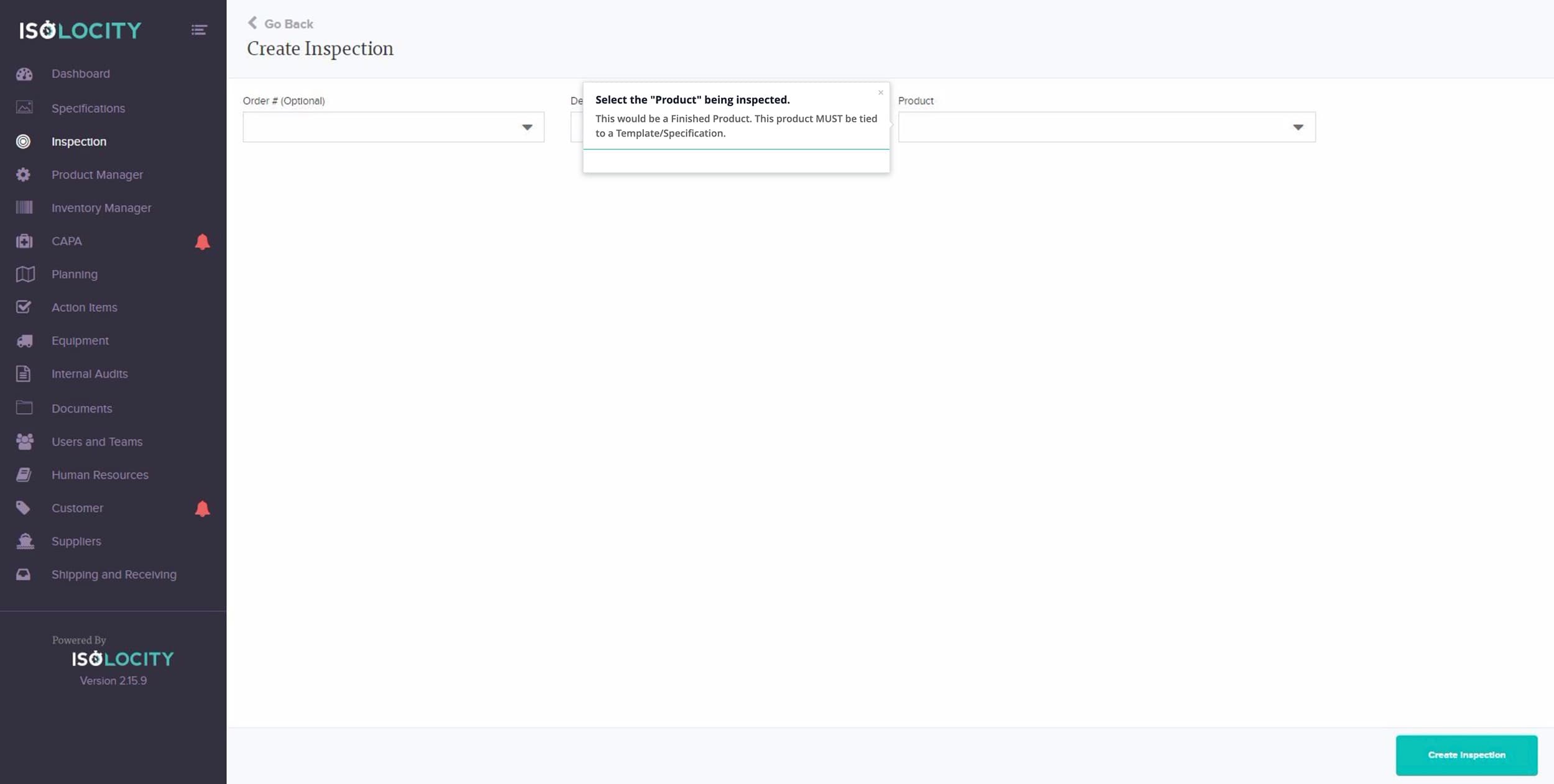

Step #6

Select the “Product” being inspected.

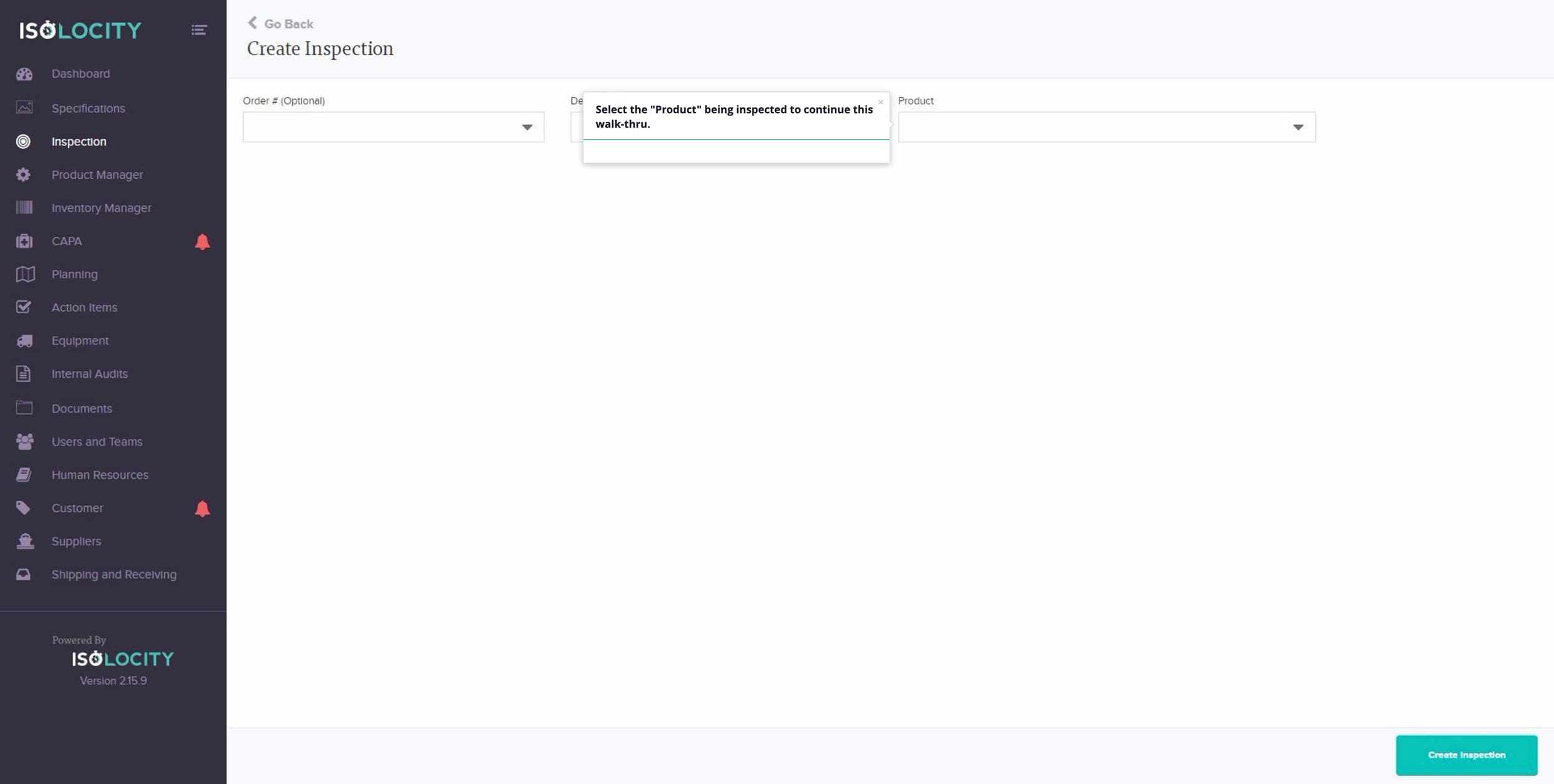

Step #7

Select the “Product” being inspected to continue this walk-thru.

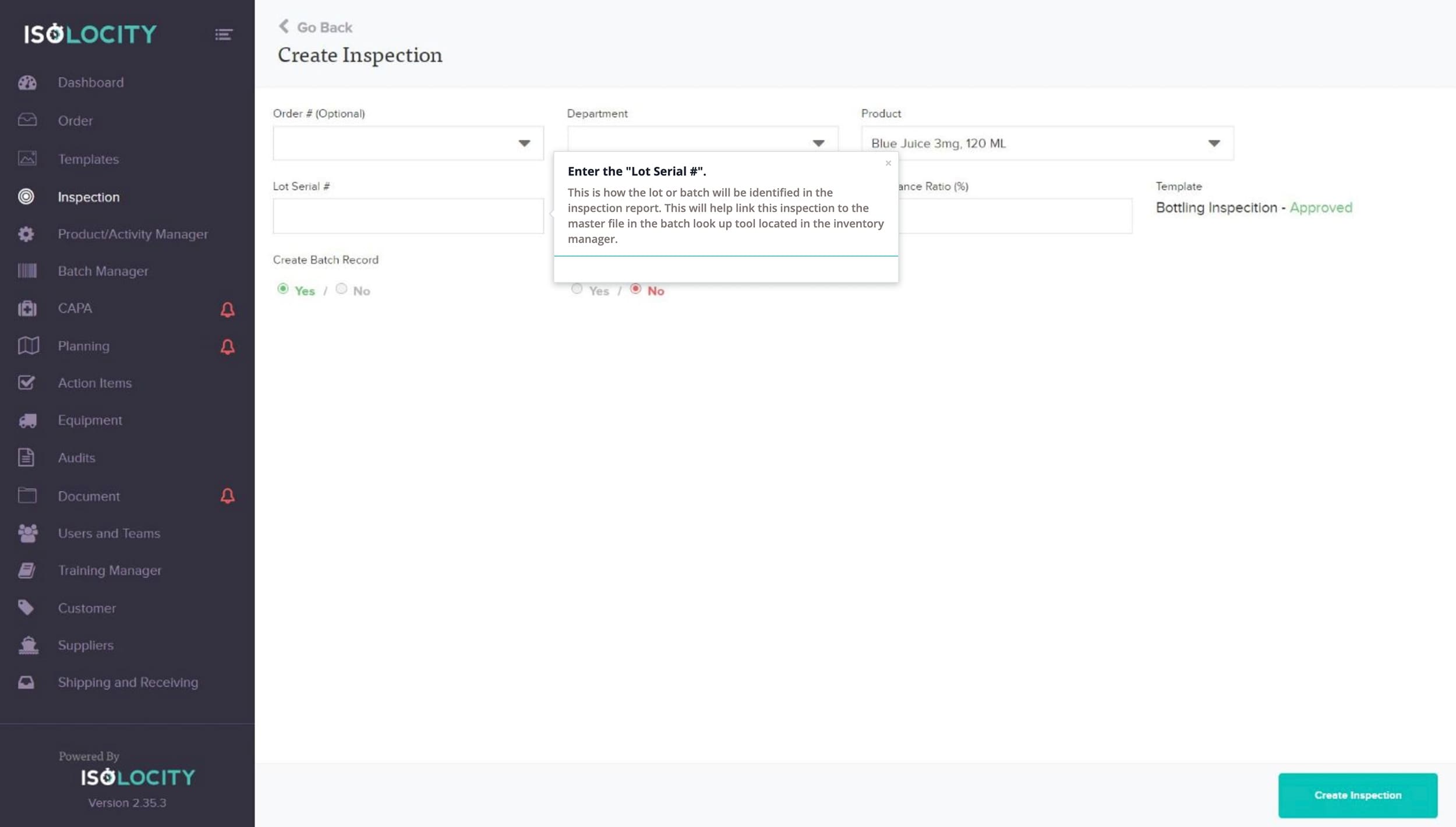

Step #8

Enter the “Lot Serial #”.

Step #9

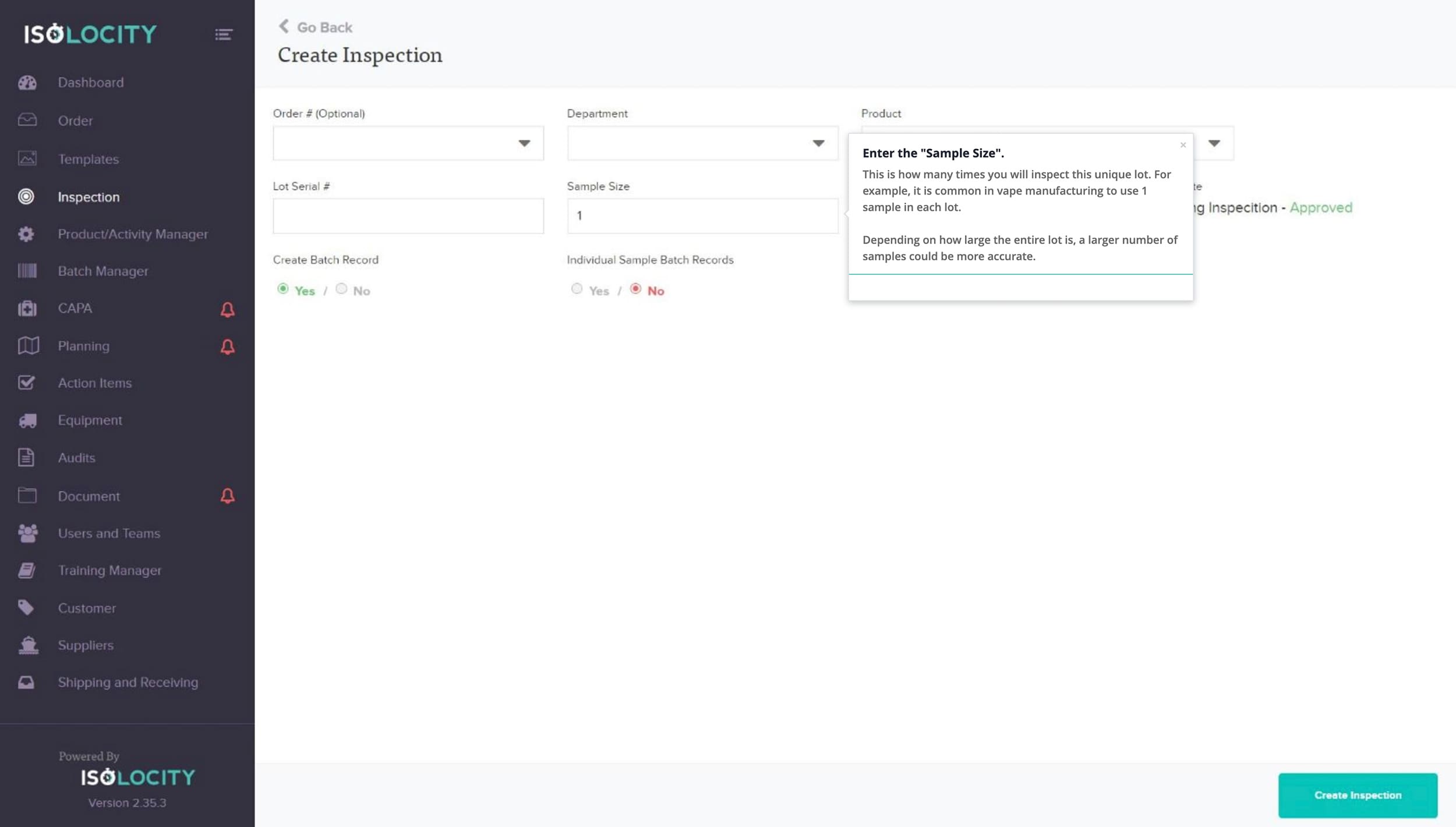

Enter the “Sample Size”.

Step #10

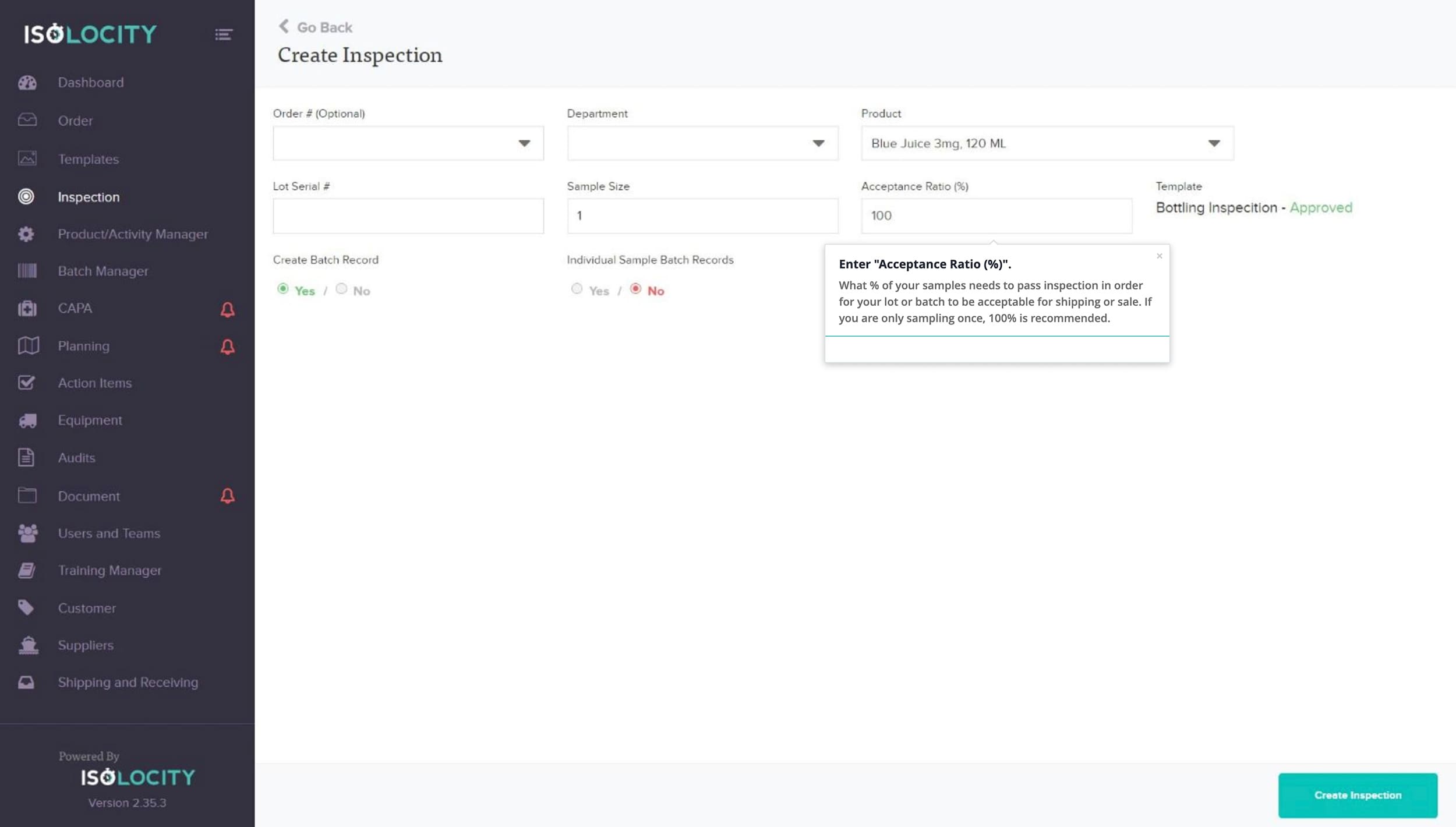

Enter “Acceptance Ratio (%)”.

Step #11

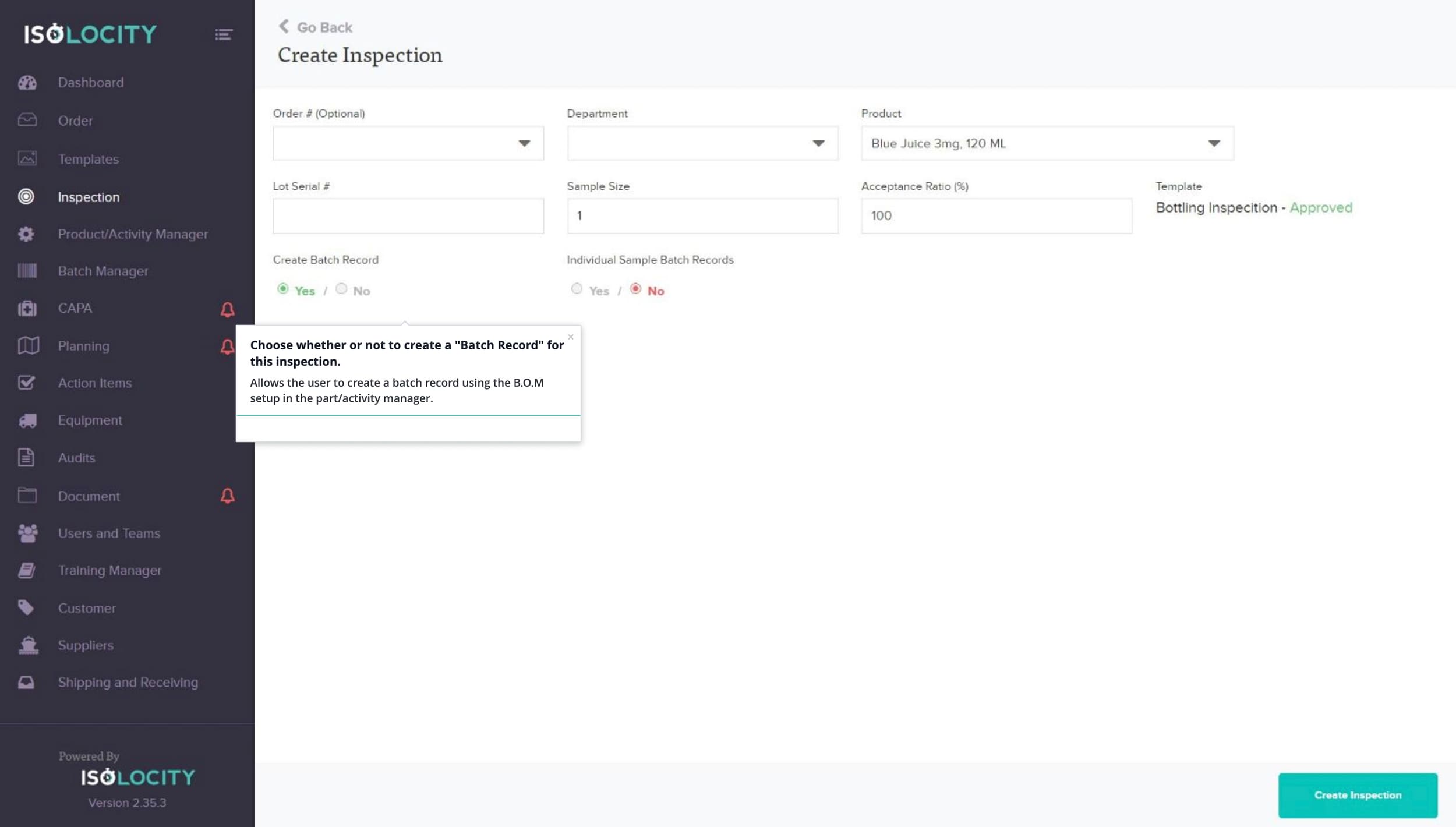

Choose whether or not to create a “Batch Record” for this inspection.

Step #12

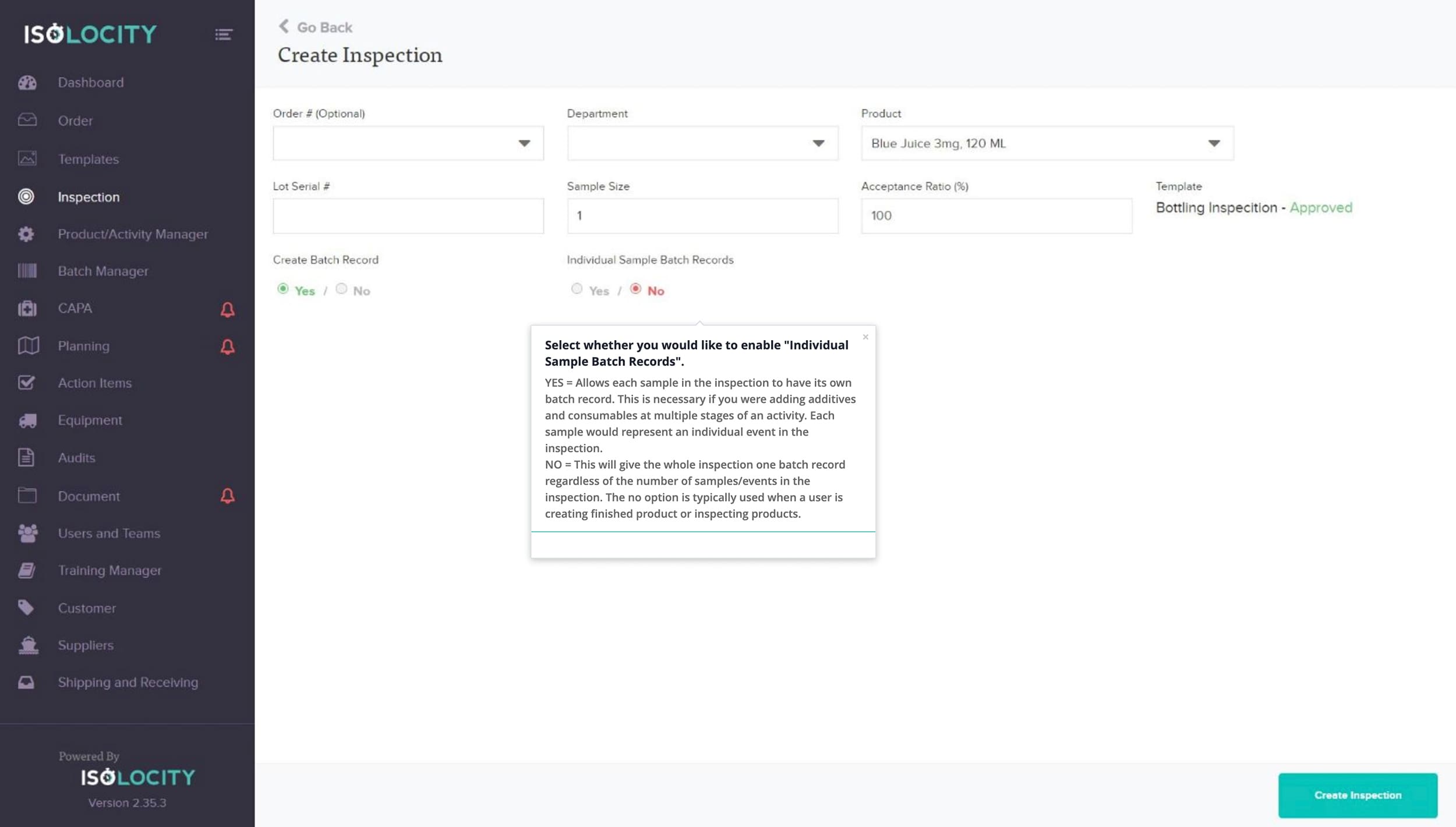

Select whether you would like to enable “Individual Sample Batch Records”.

Step #13

Click here to create the “Inspection”.

Step 14

Errors on screen! Fix errors then click “Create Inspection”

Step 15

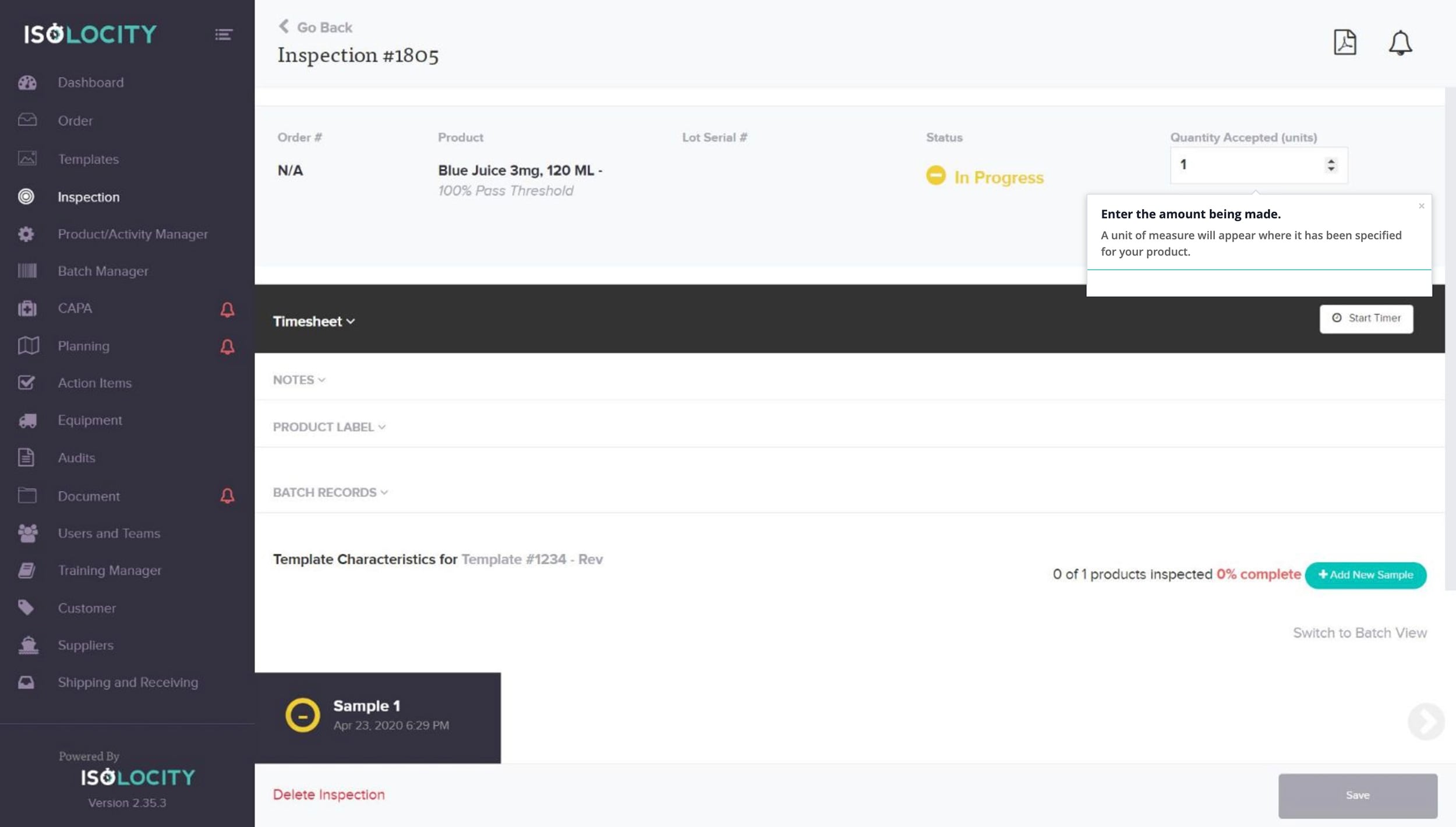

Enter the amount being made.

Step 16

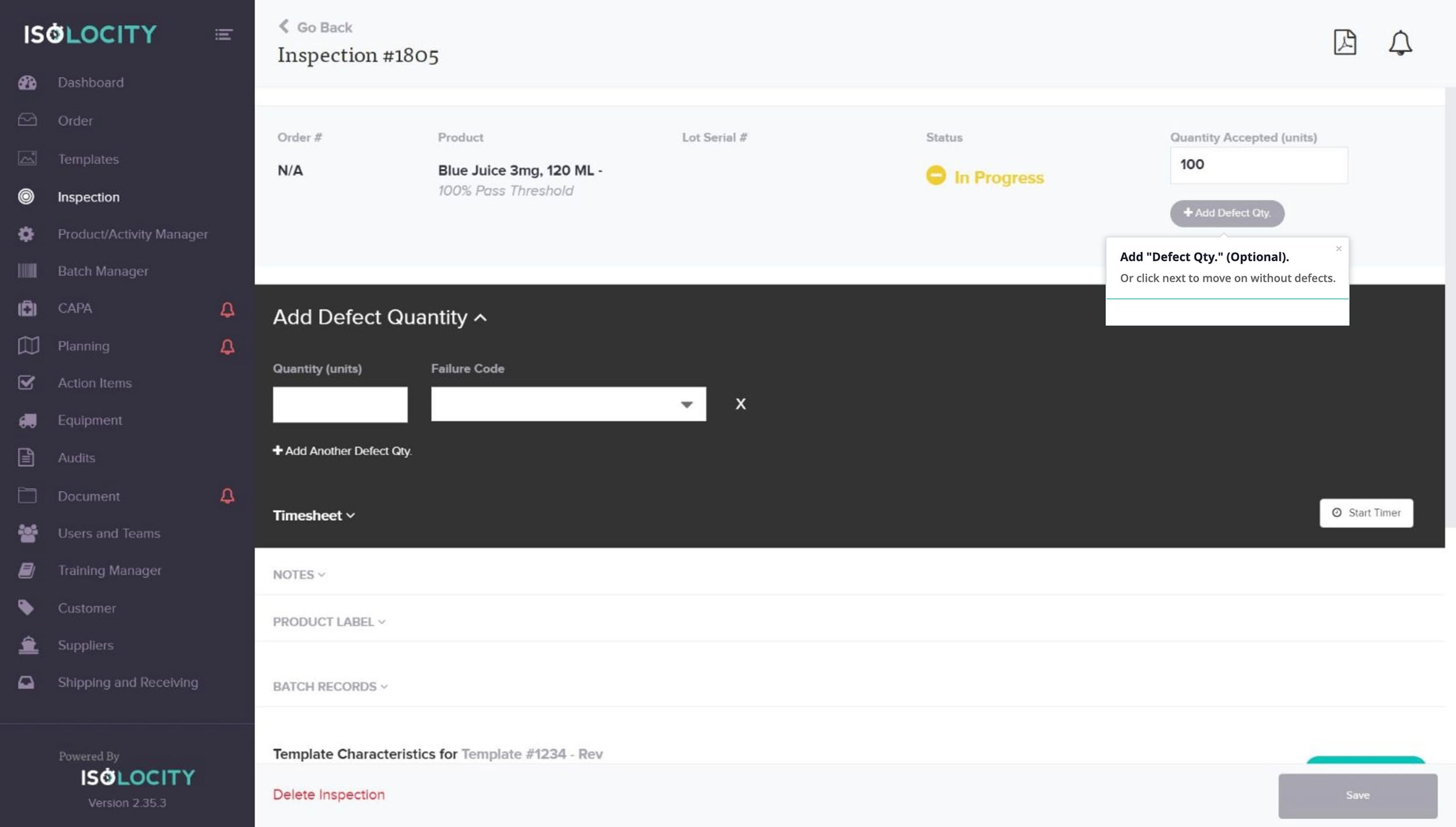

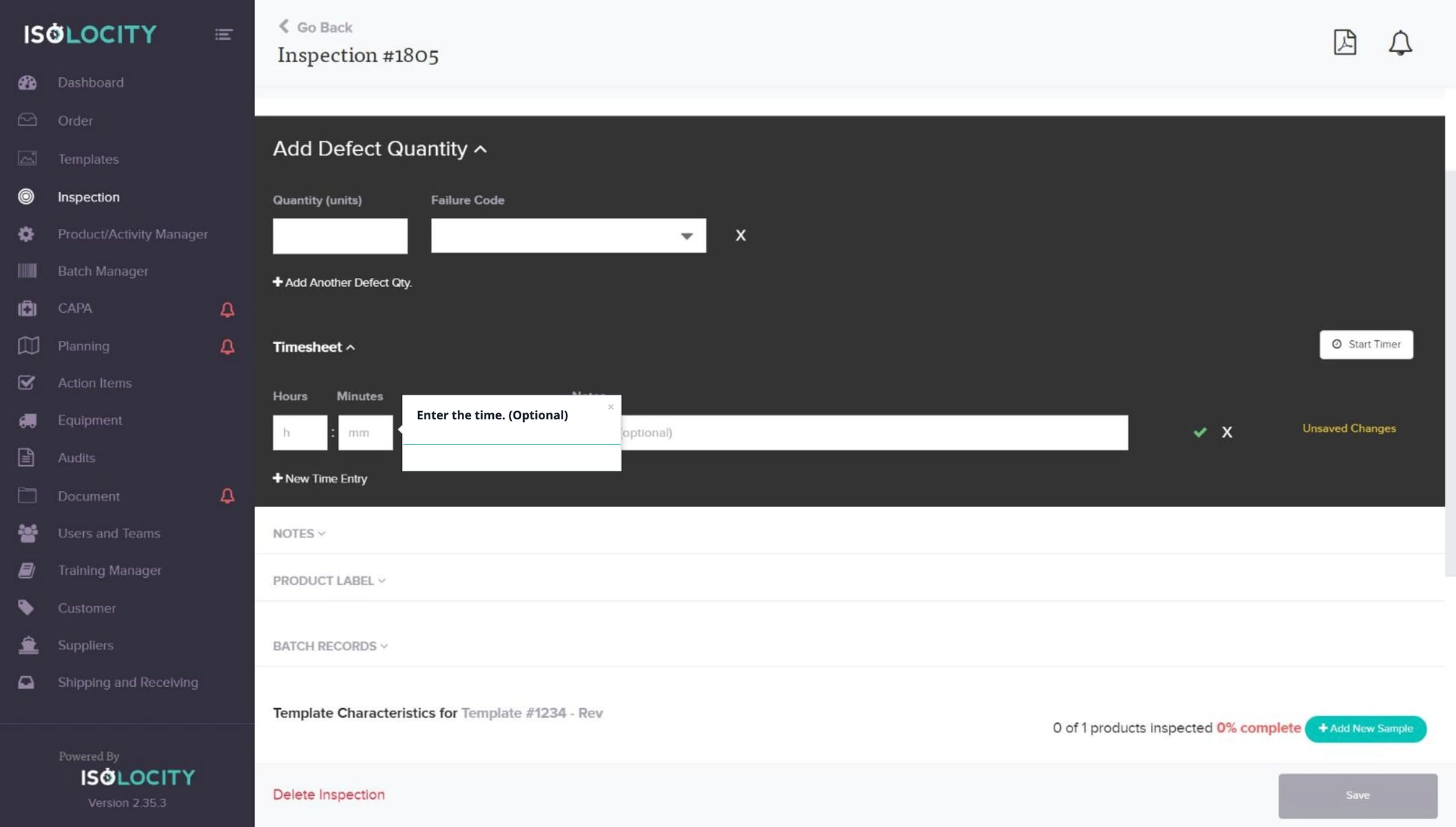

Add “Defect Qty.” (Optional).

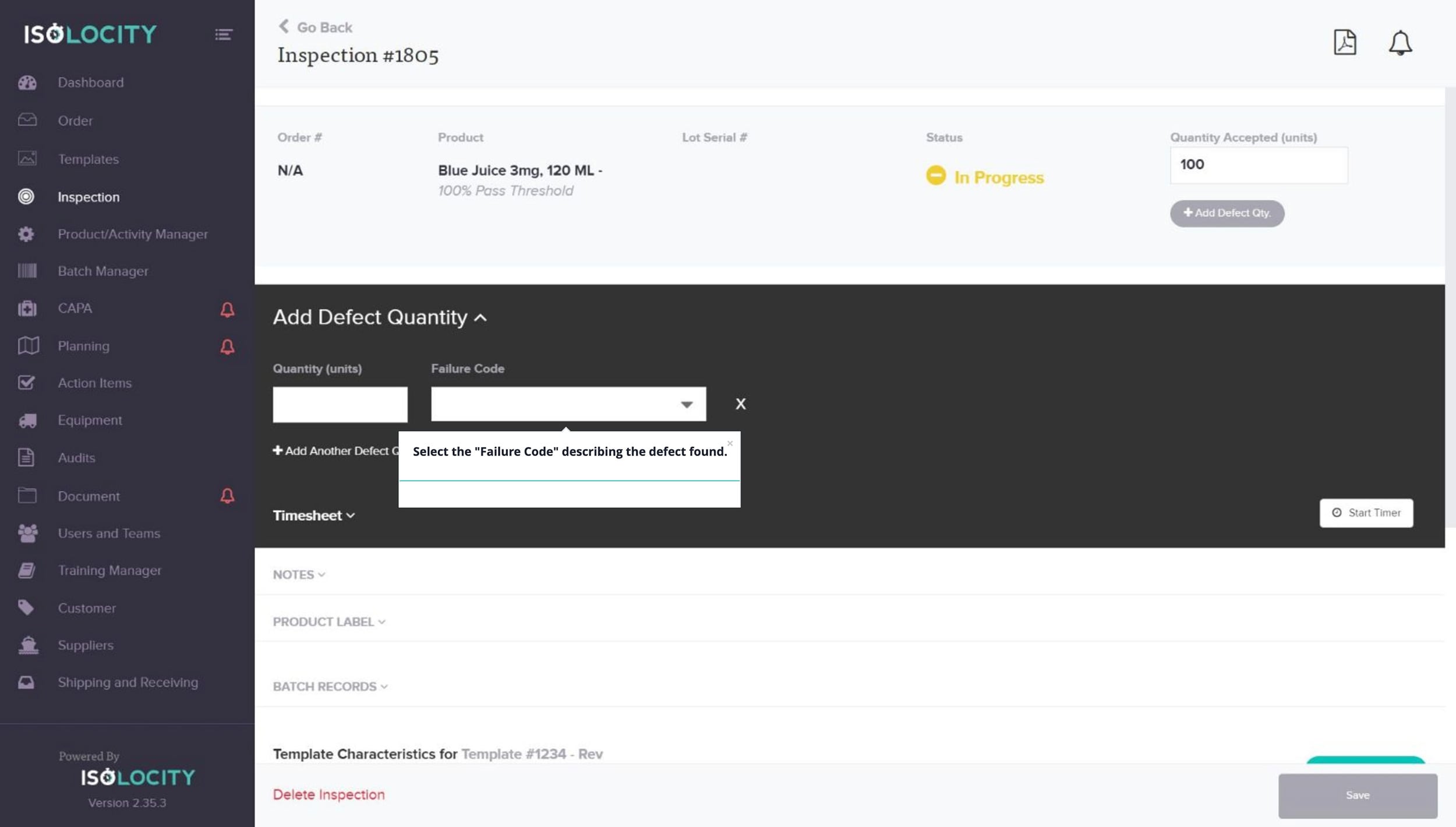

Step 17

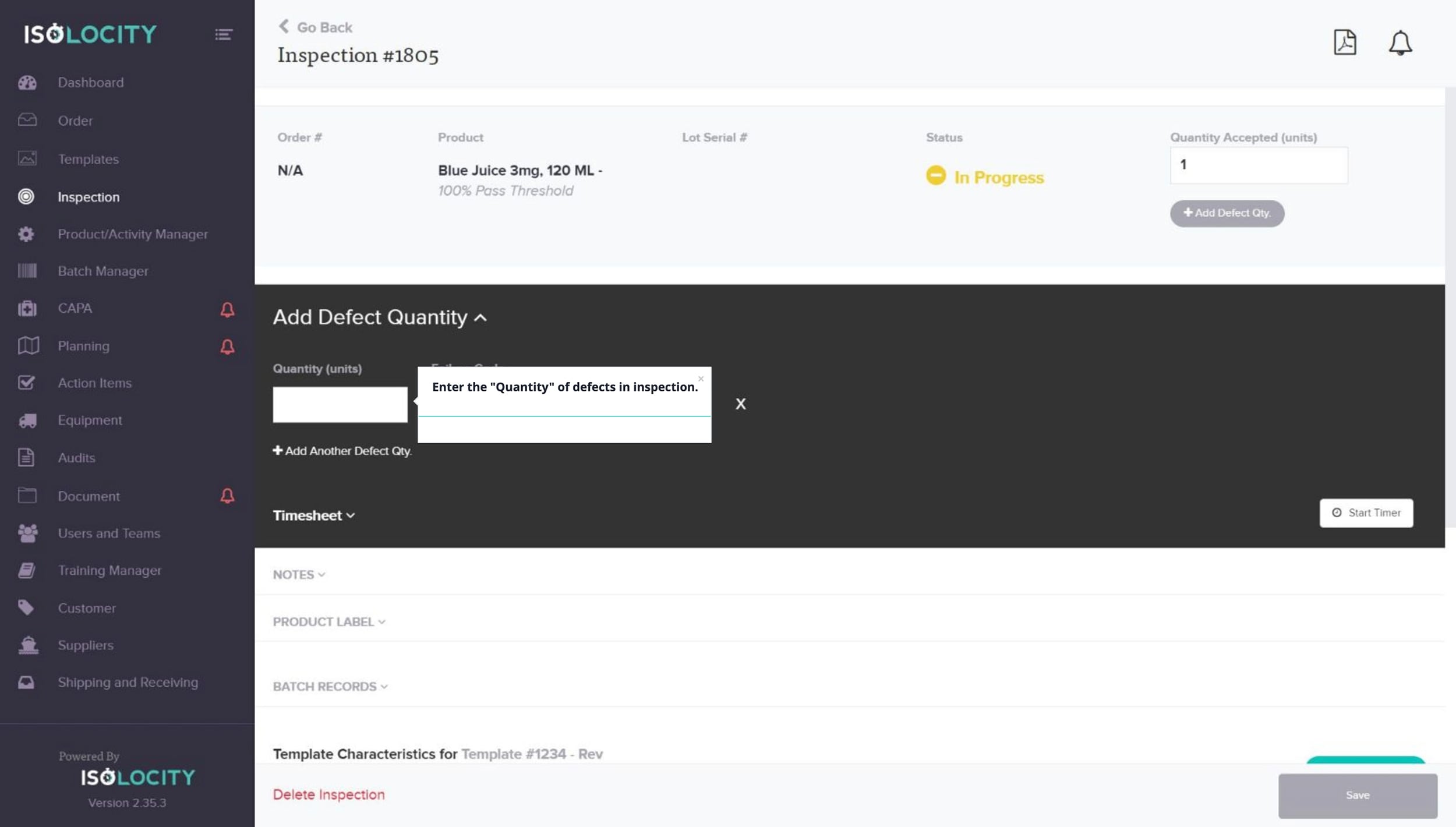

Enter the “Quantity” of defects in inspection.

Step 18

Select the “Failure Code” describing the defect found.

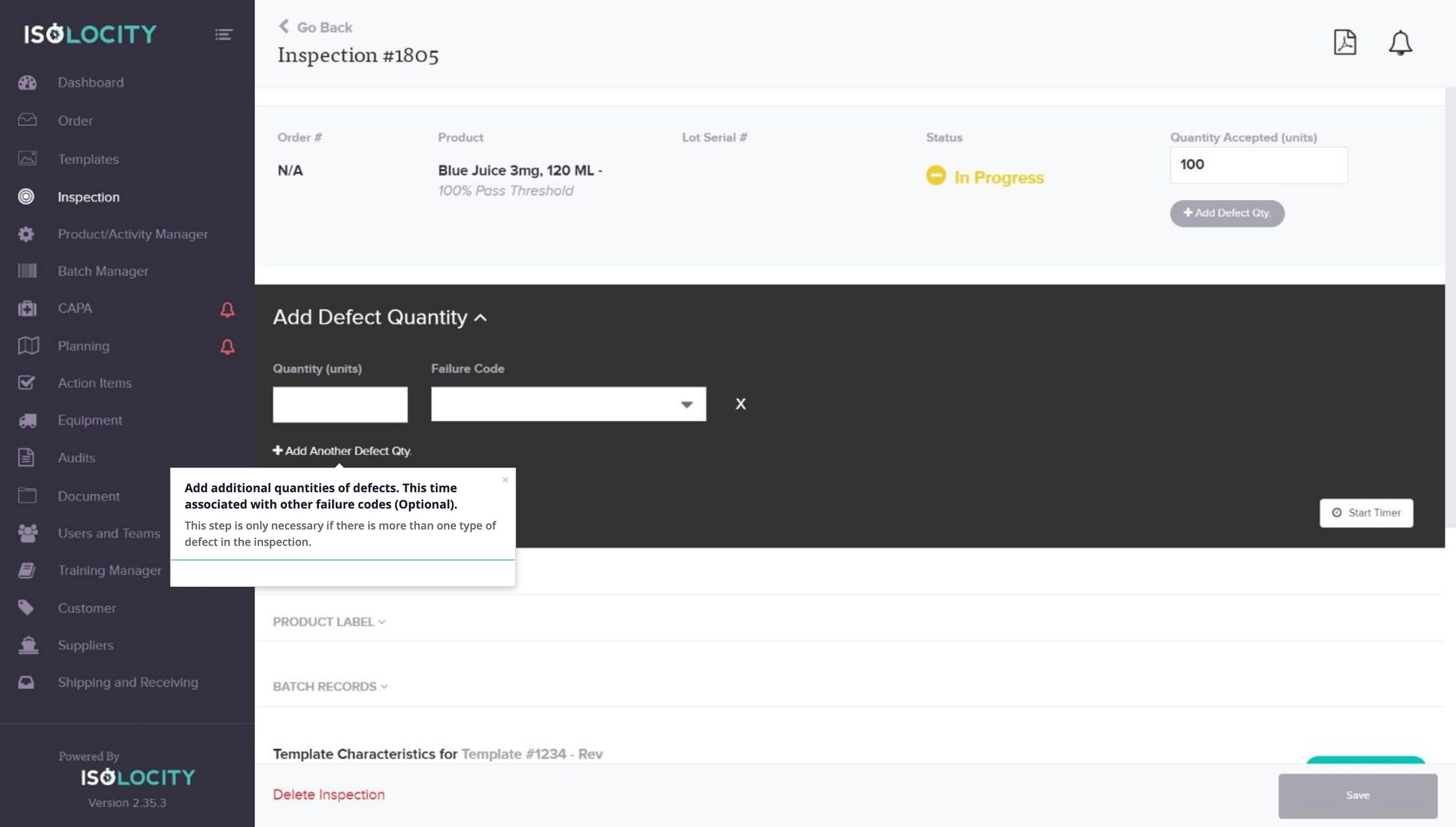

Step 19

Add additional quantities of defects. This time associated with other failure codes (Optional).

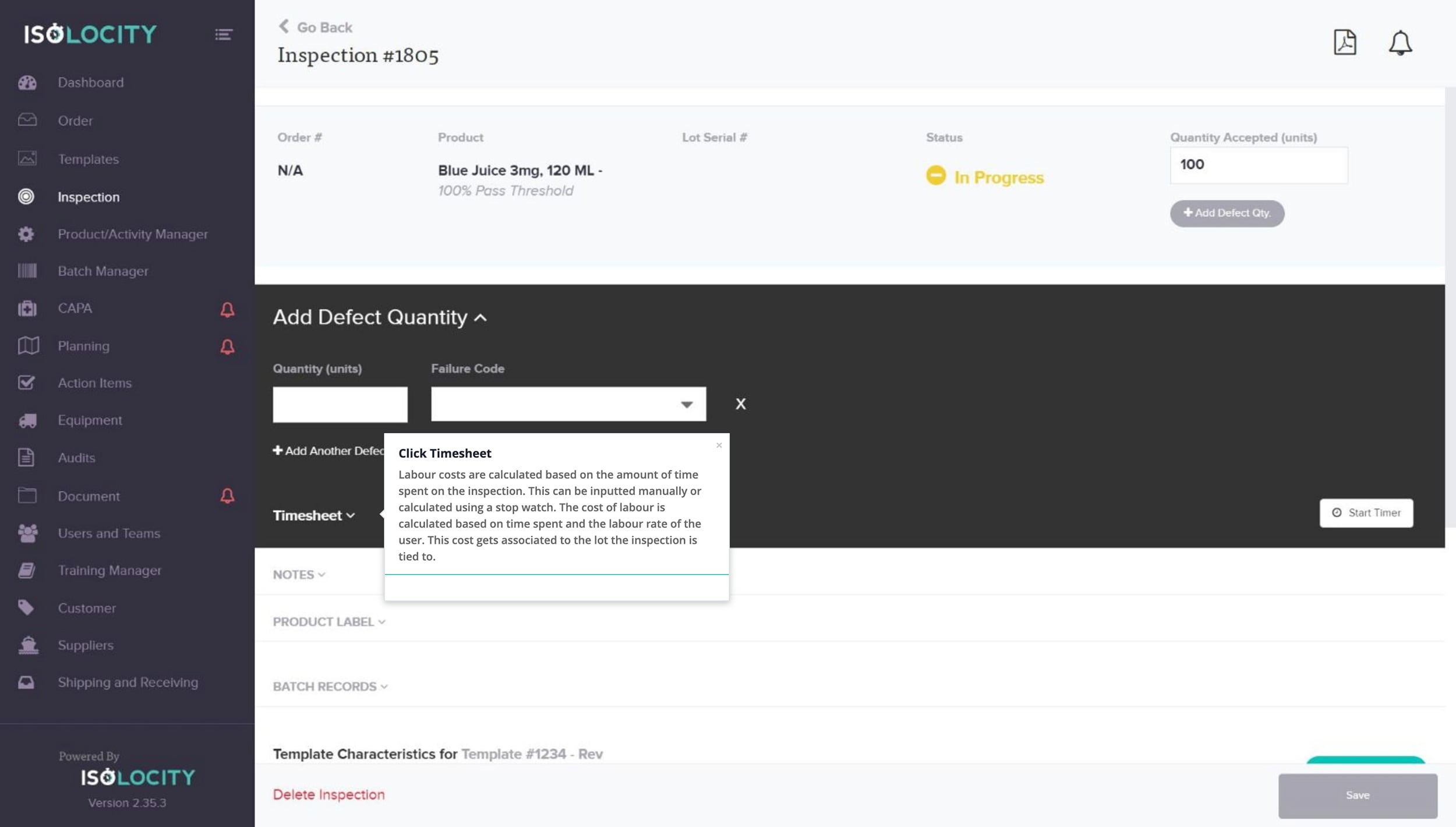

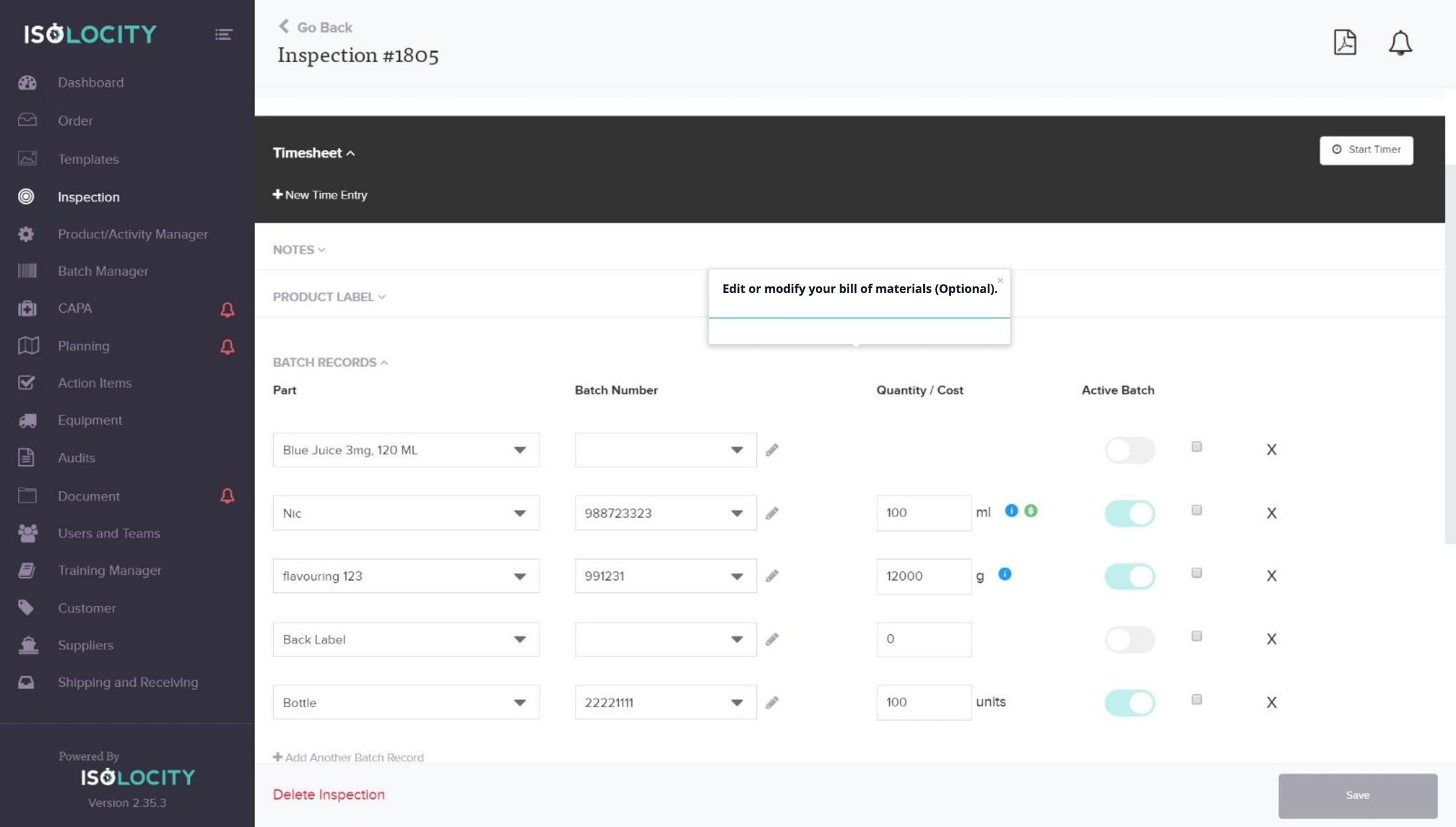

Step 20

Click Timesheet

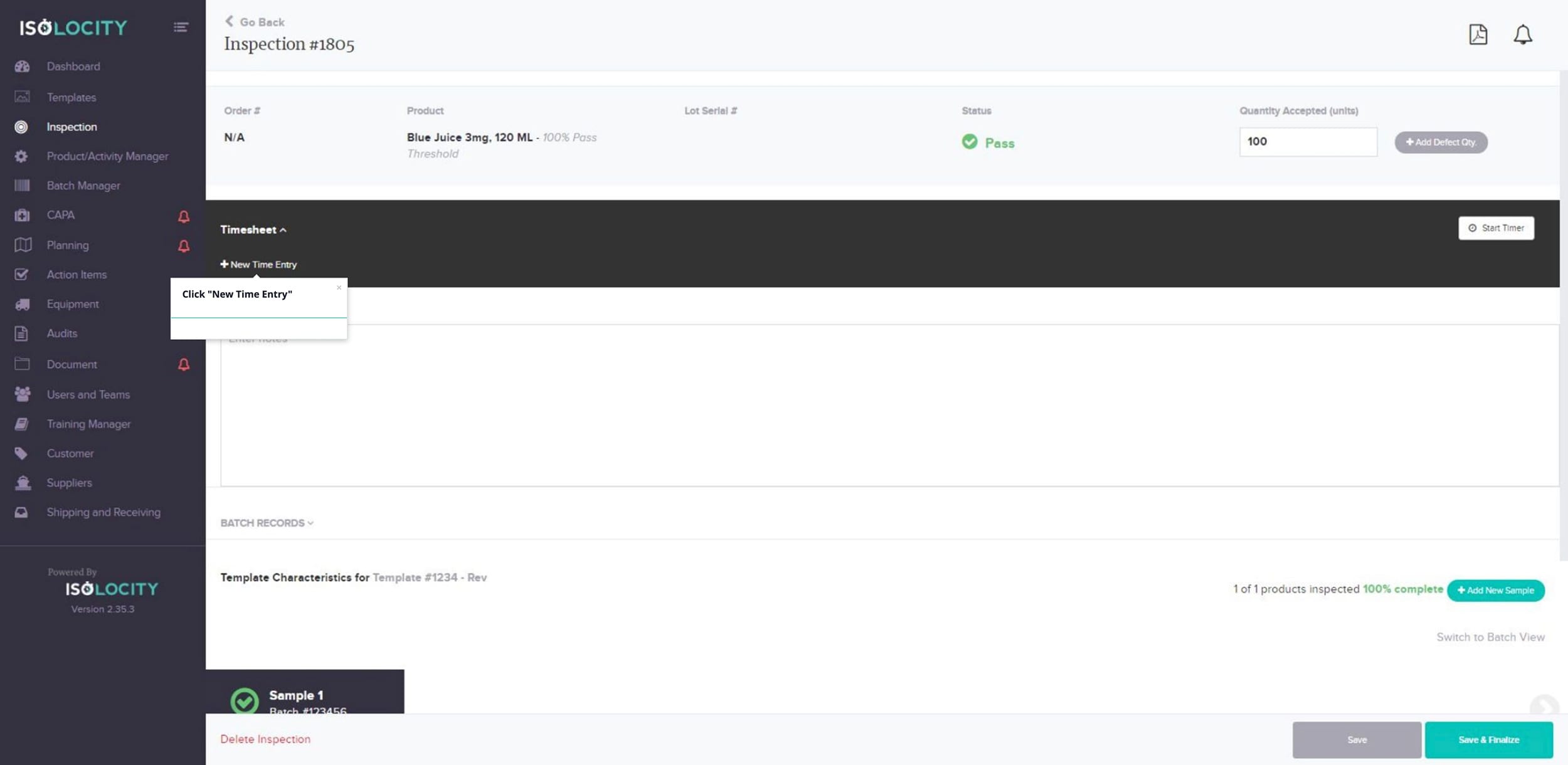

Step 21

Click “New Time Entry”

Step 22

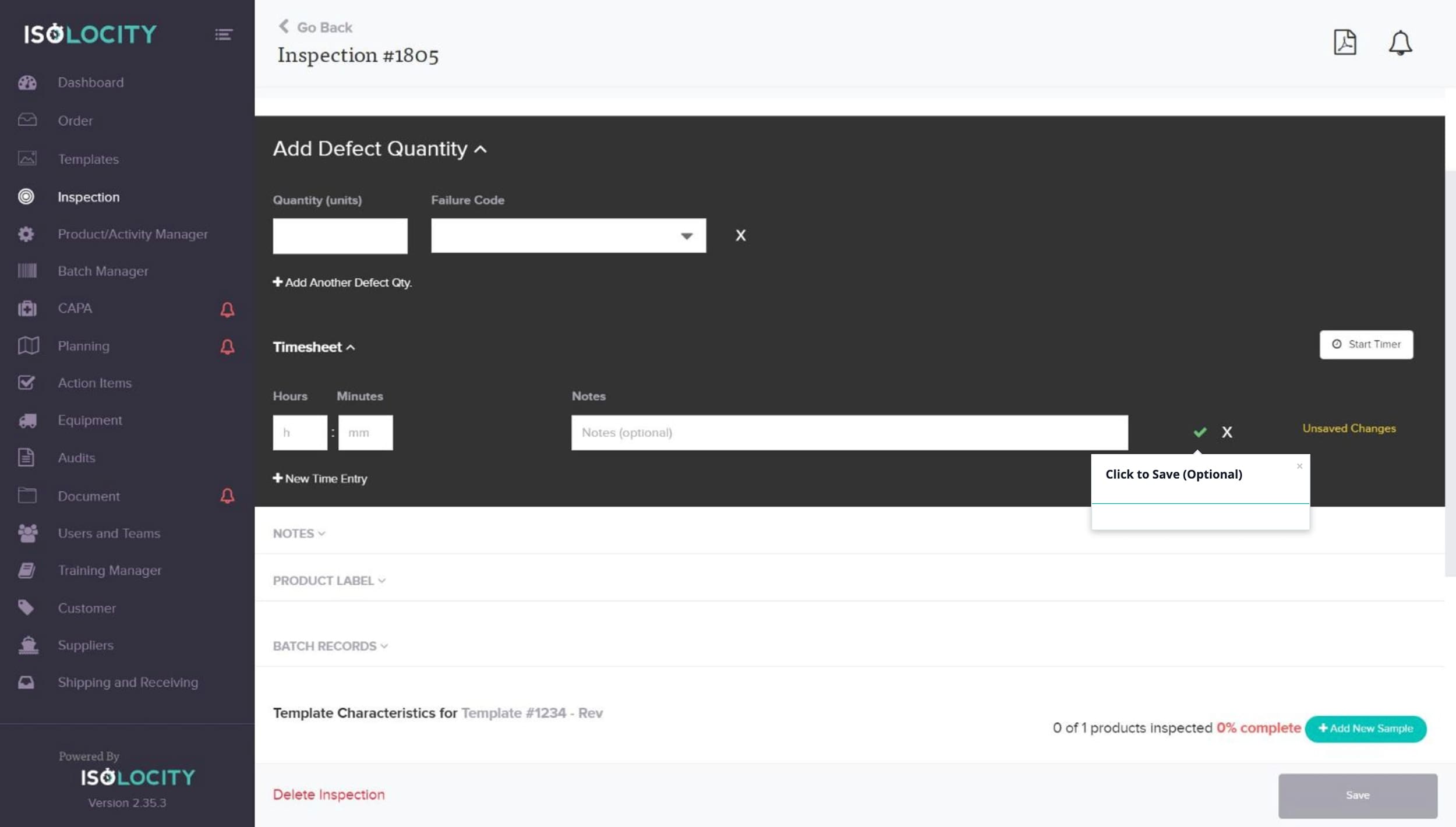

Enter the time. (Optional)

Step 23

Click to Save (Optional)

Step 24

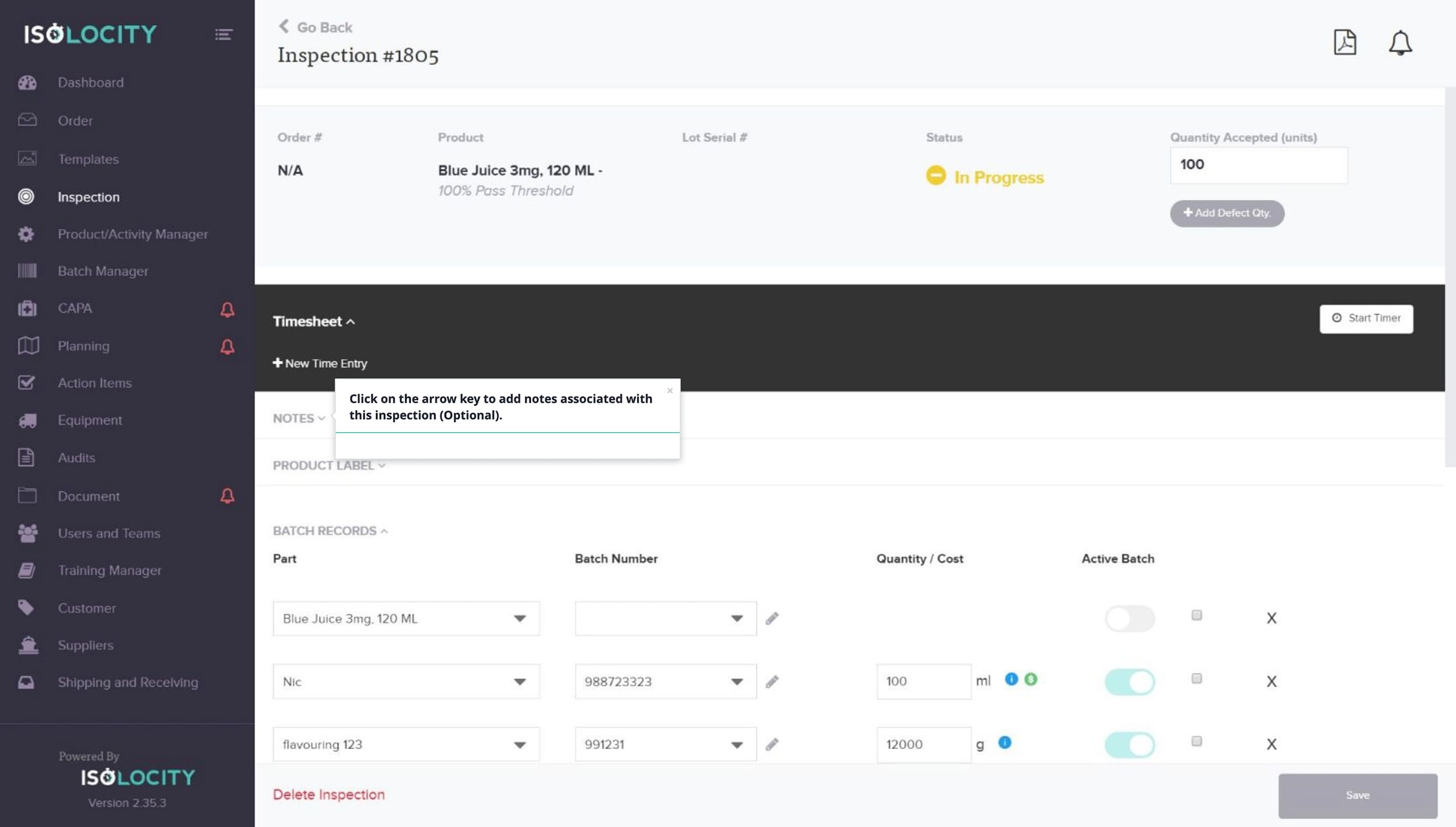

Click on the arrow key to add notes associated with this inspection (Optional).

Step 25

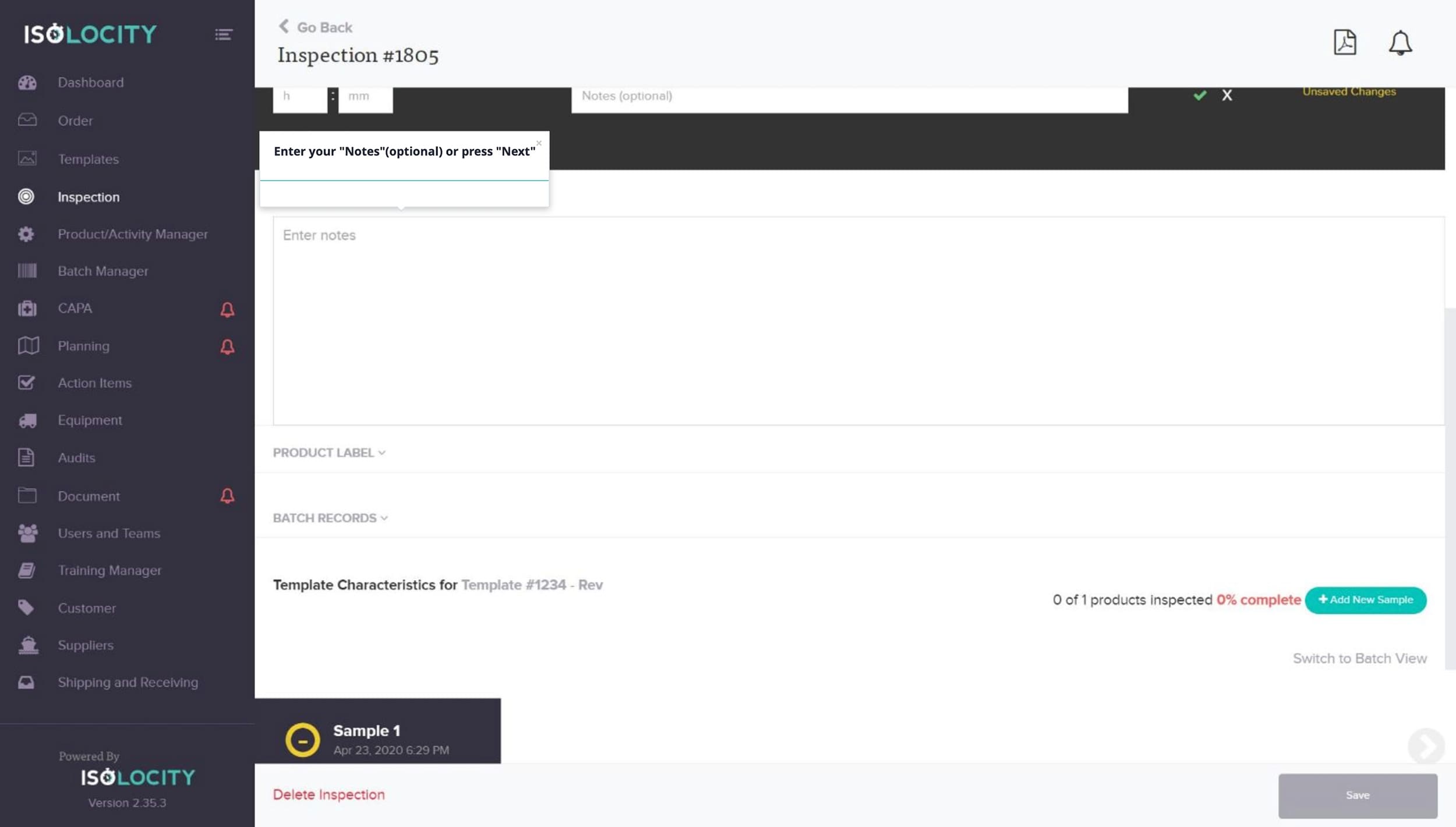

Enter your “Notes”(optional) or press “Next”

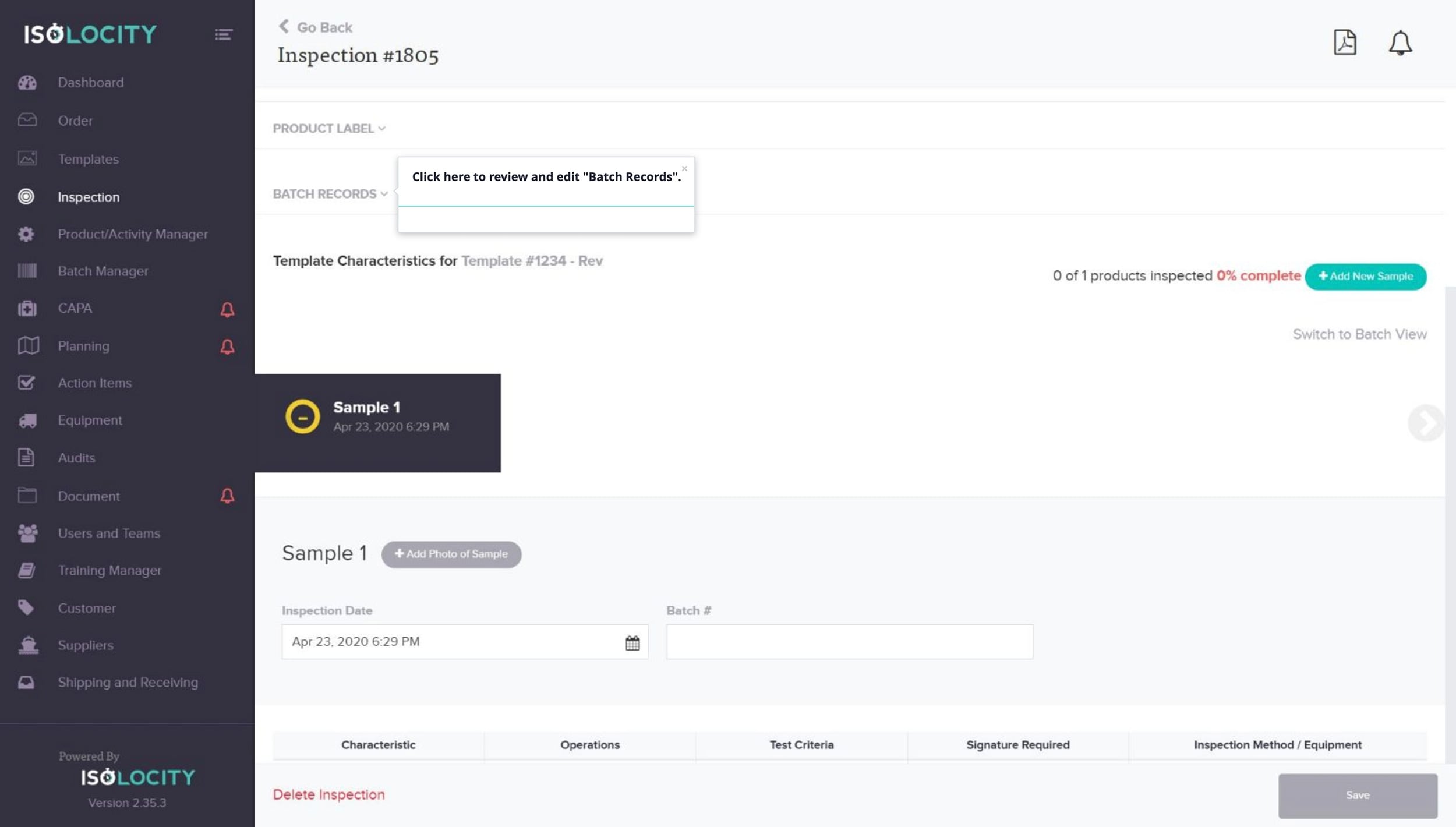

Step 26

Click here to review and edit “Batch Records”.

Step 27

Edit or modify your bill of materials (Optional).

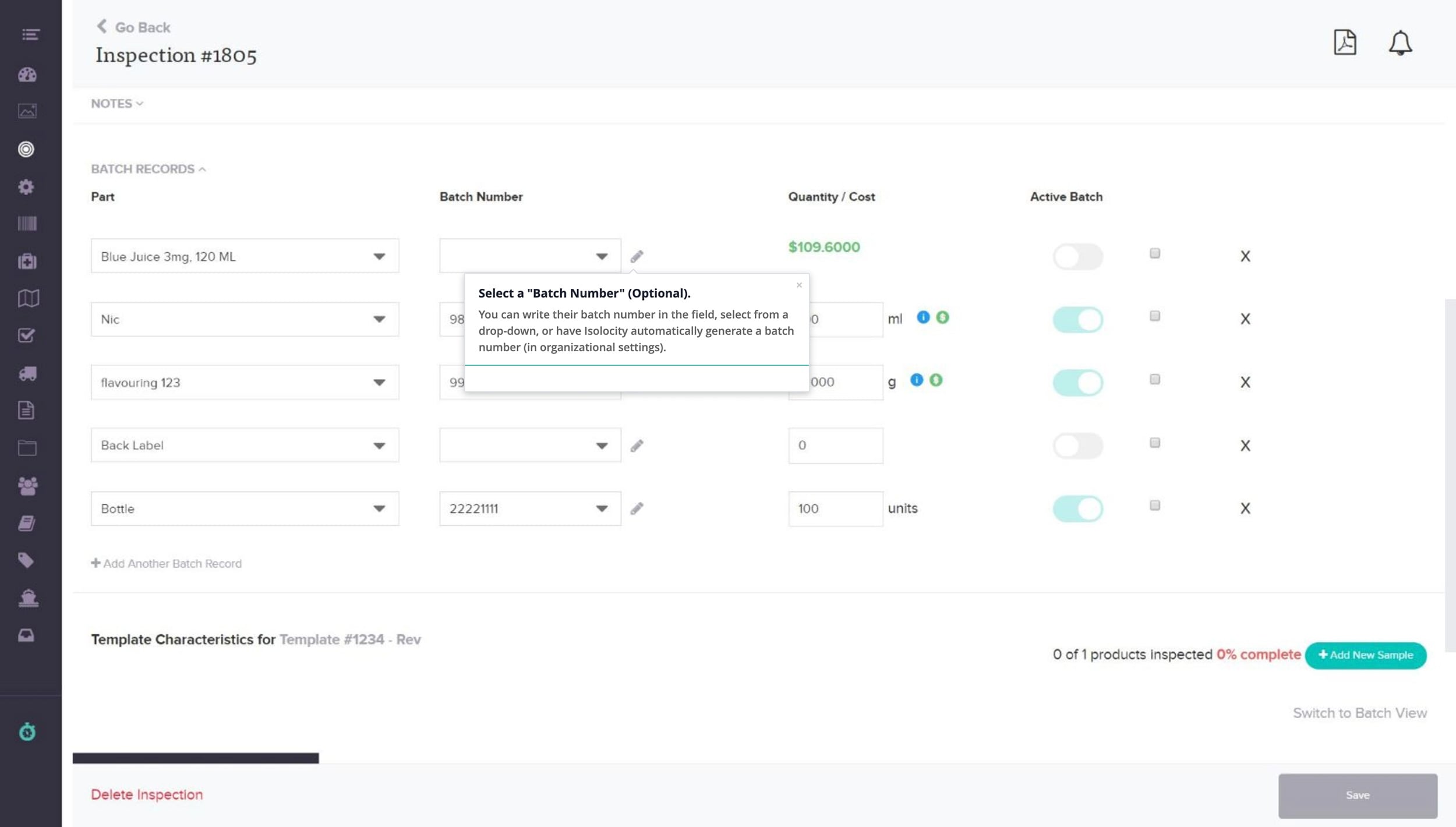

Step 28

Select a “Batch Number” (Optional).

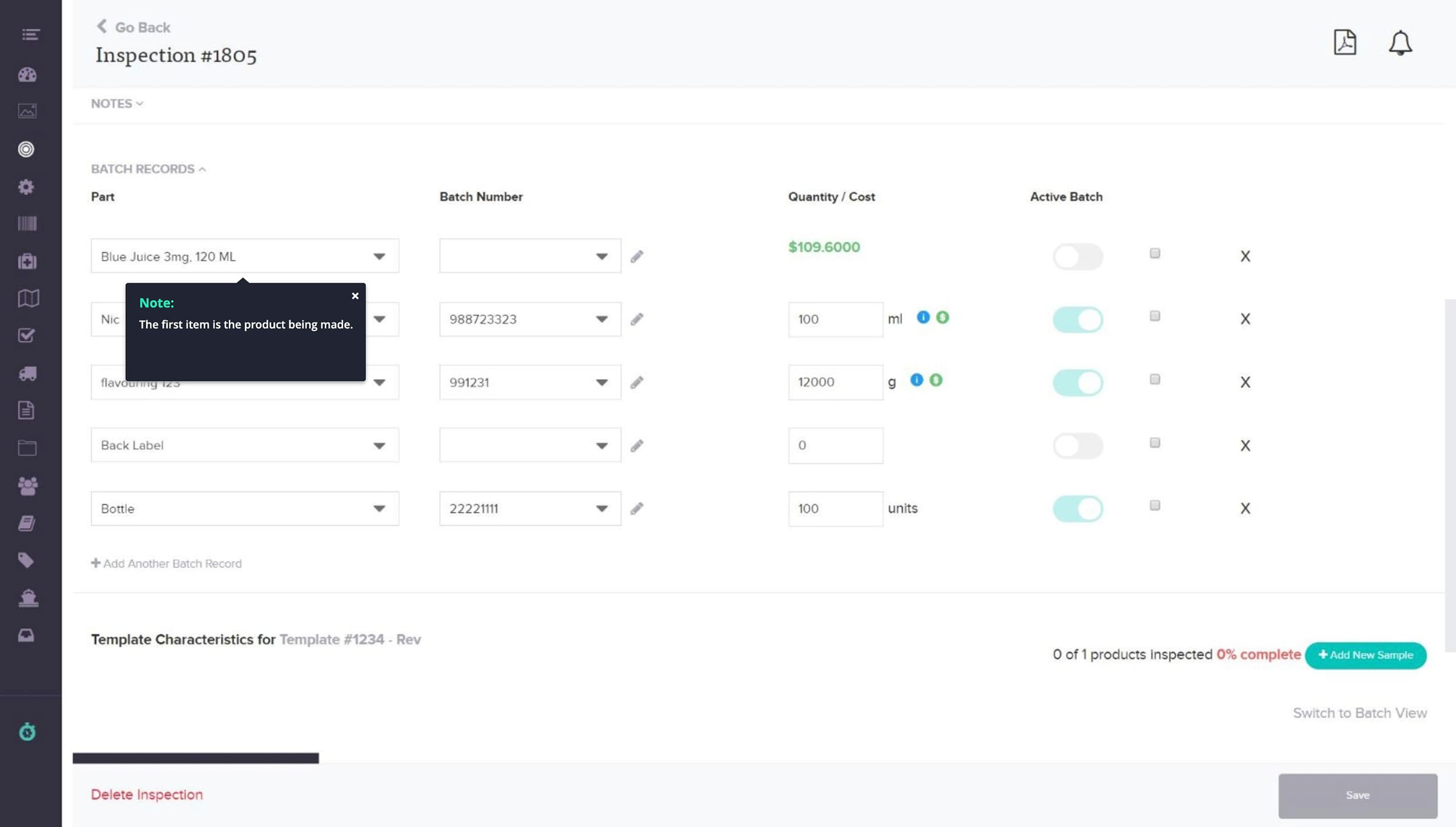

Step 29

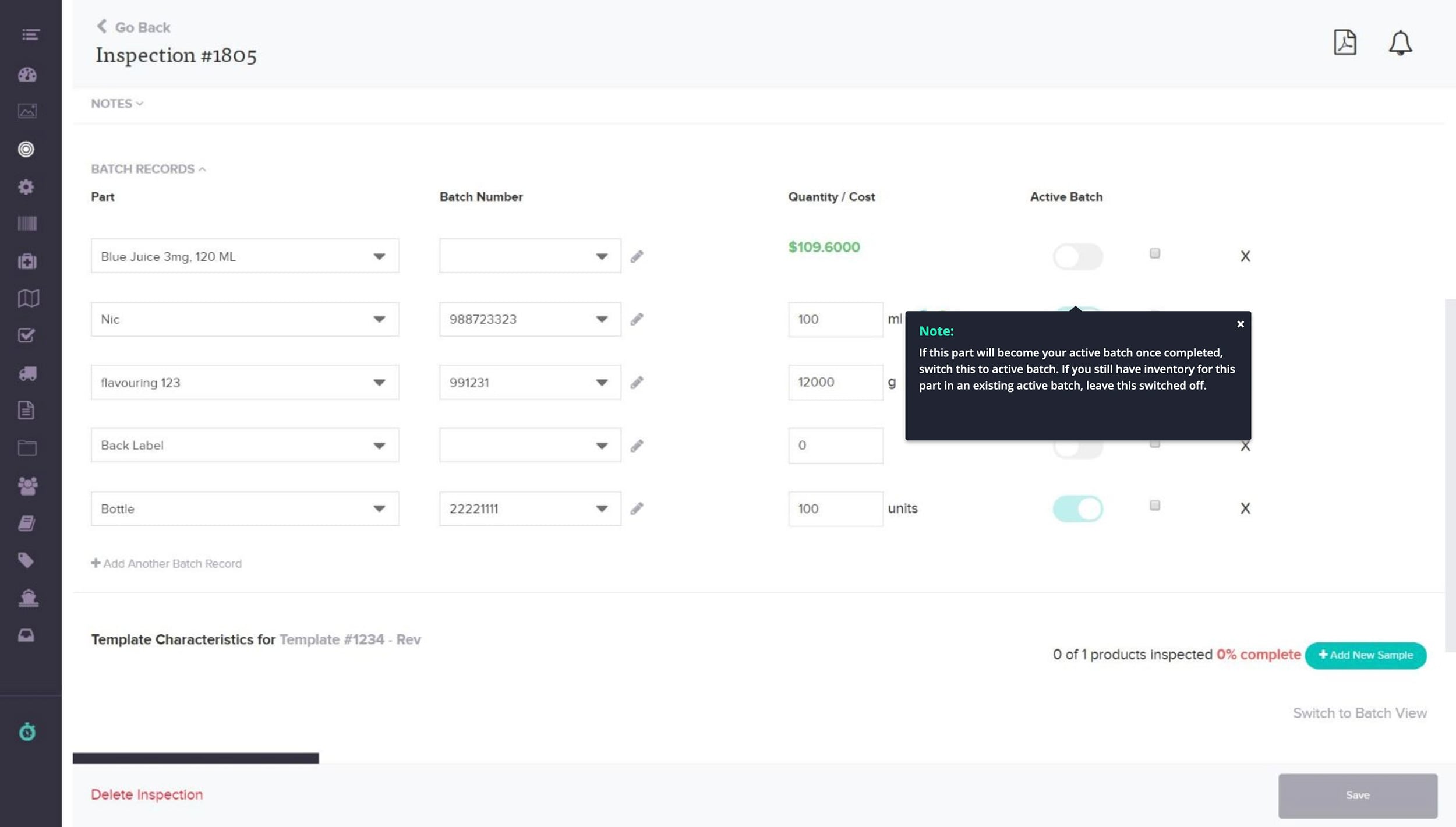

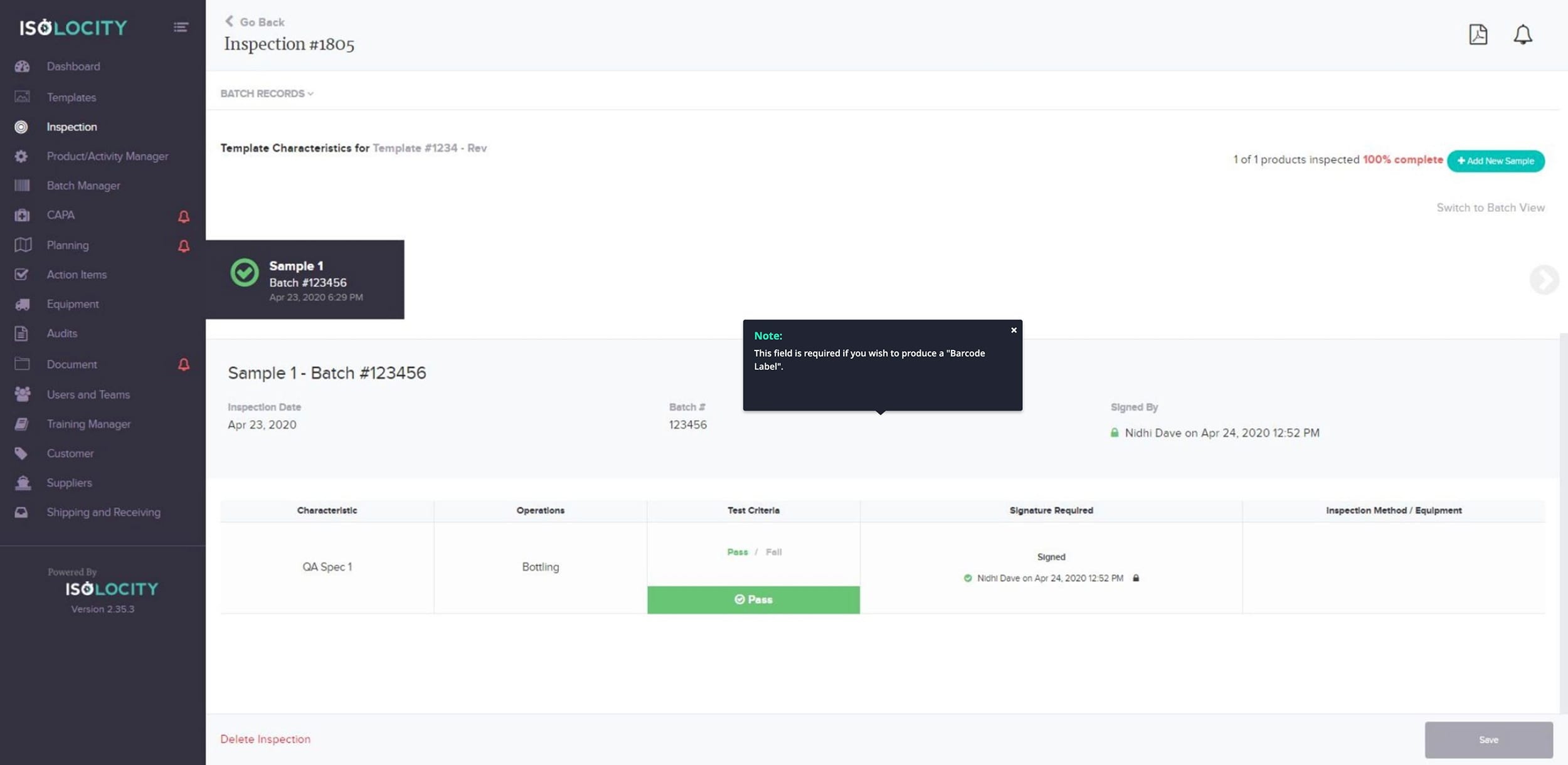

Note:

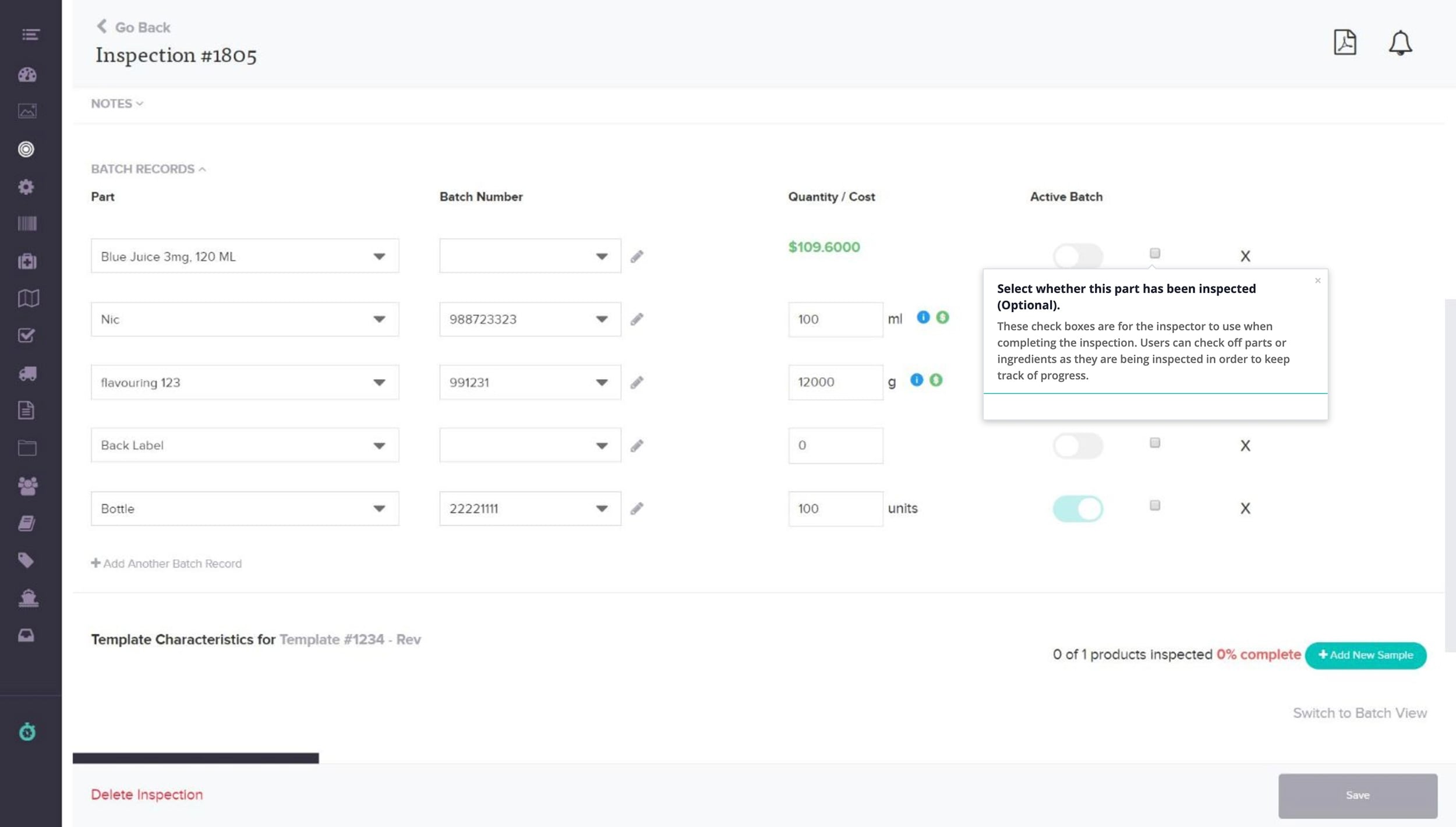

Step 30

Select whether this part has been inspected (Optional).

Step 31

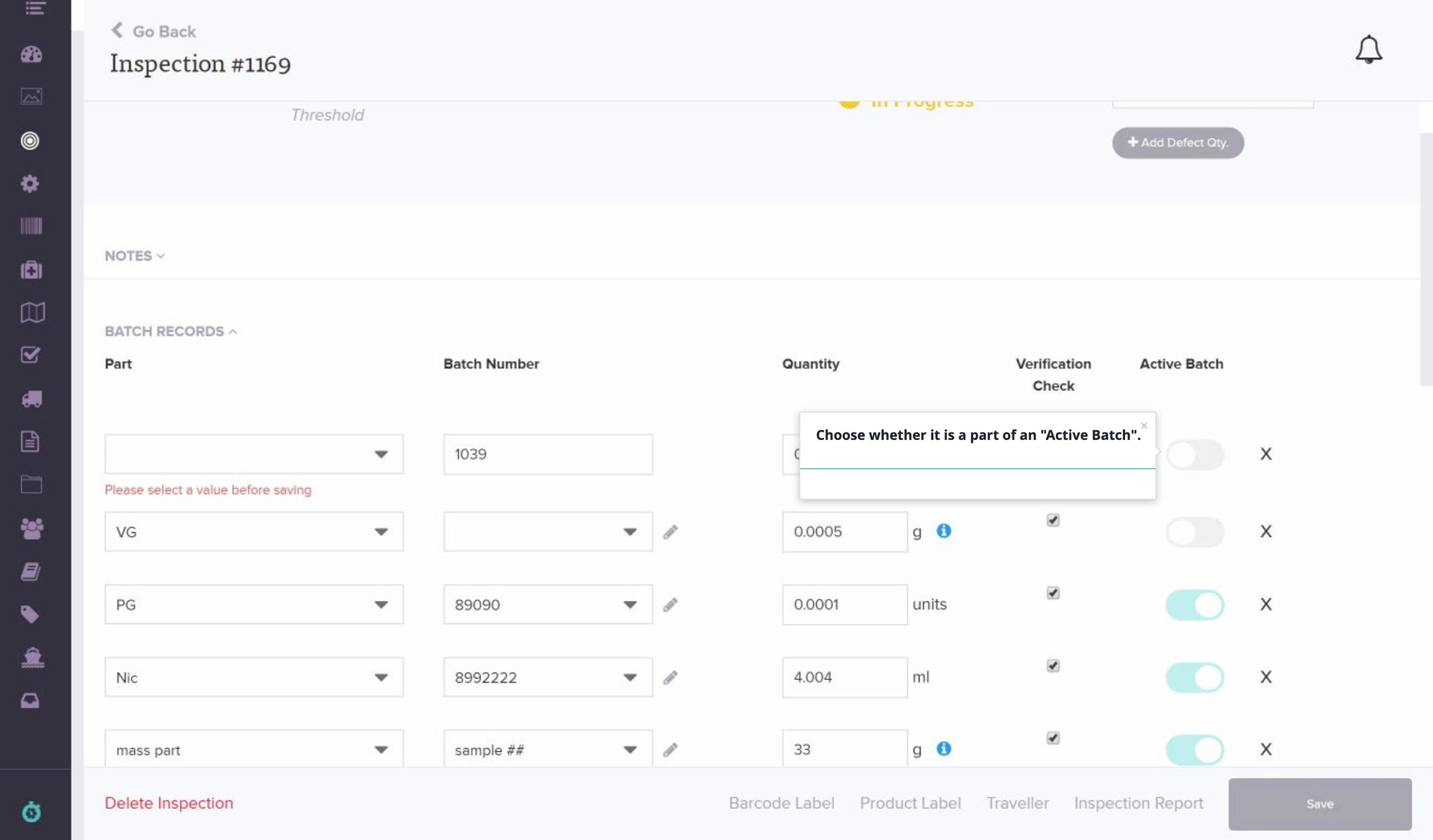

Note:

Step 32

Choose whether it is a part of an “Active Batch”.

Step 33

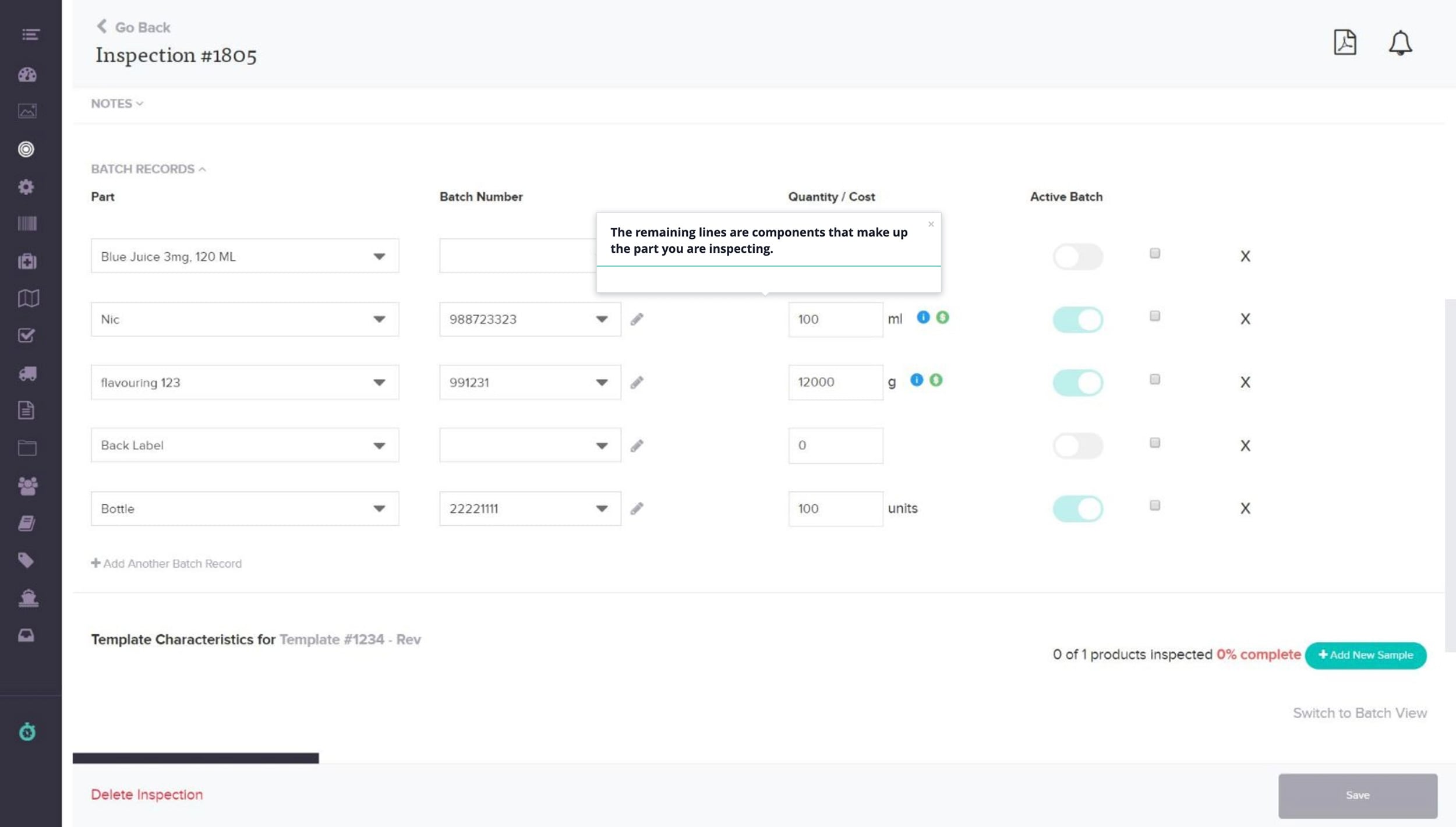

The remaining lines are components that make up the part you are inspecting.

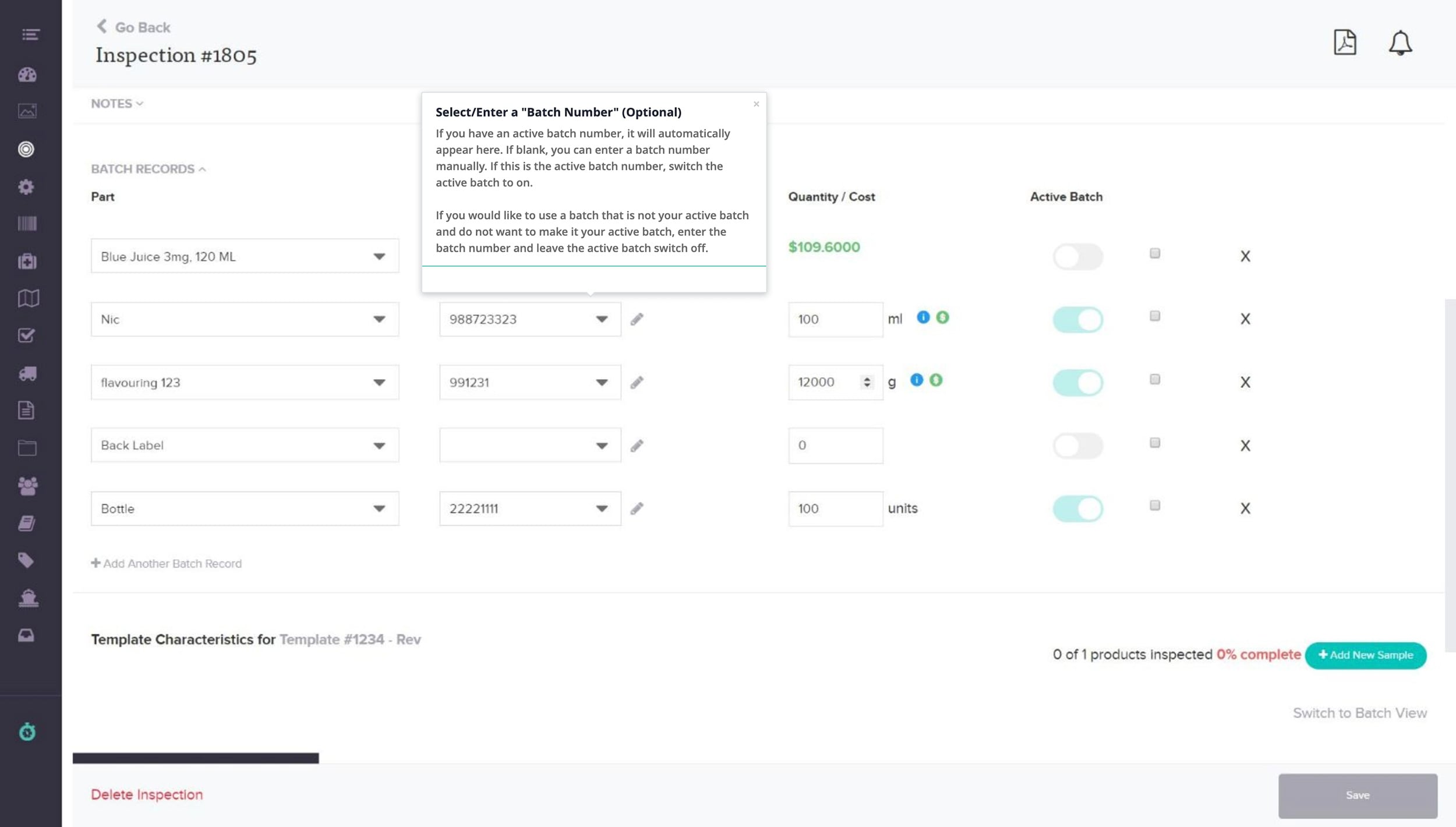

Step 34

Select/Enter a “Batch Number” (Optional)

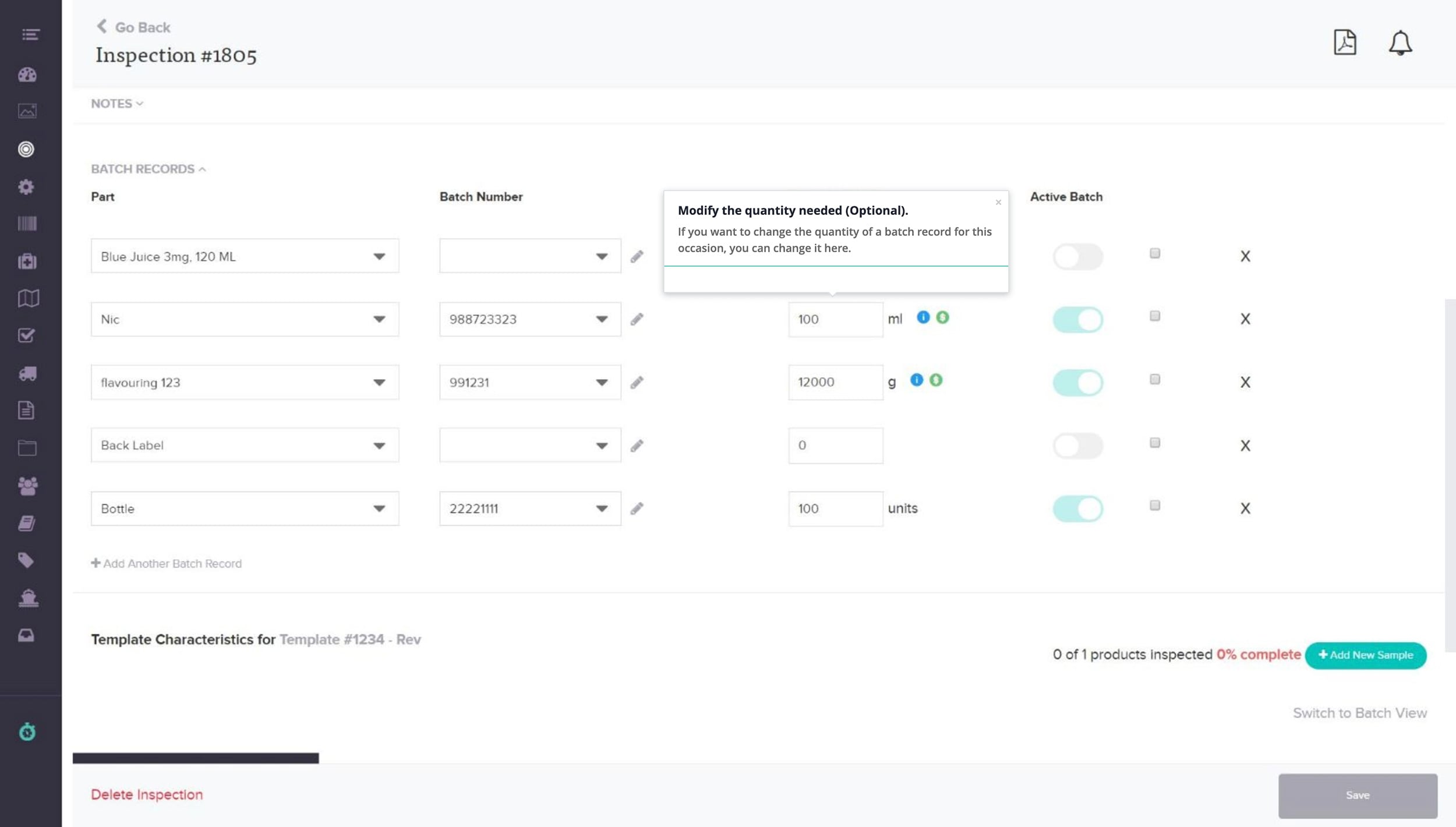

Step 35

Modify the quantity needed (Optional).

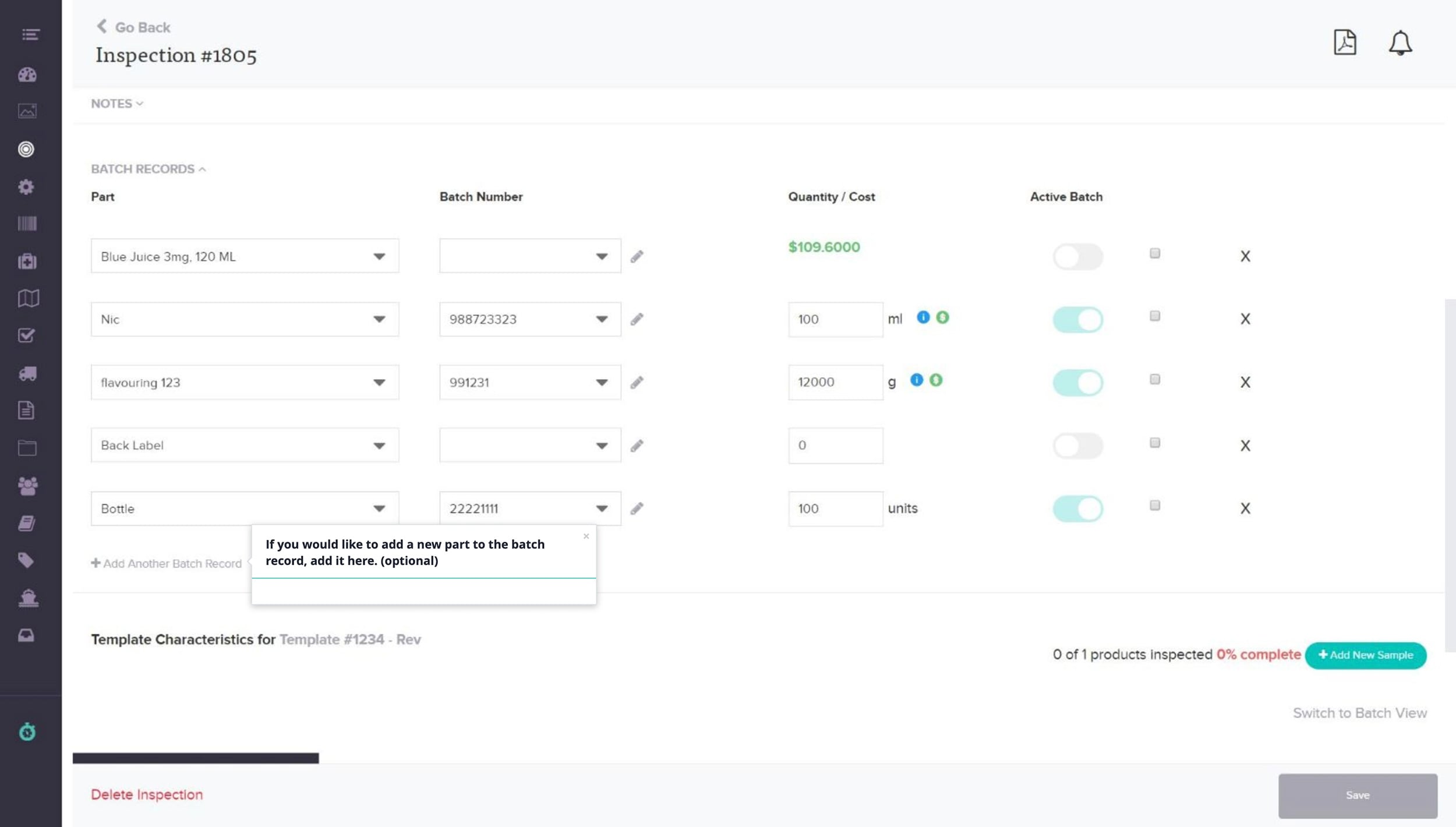

Step 36

If you would like to add a new part to the batch record, add it here. (optional)

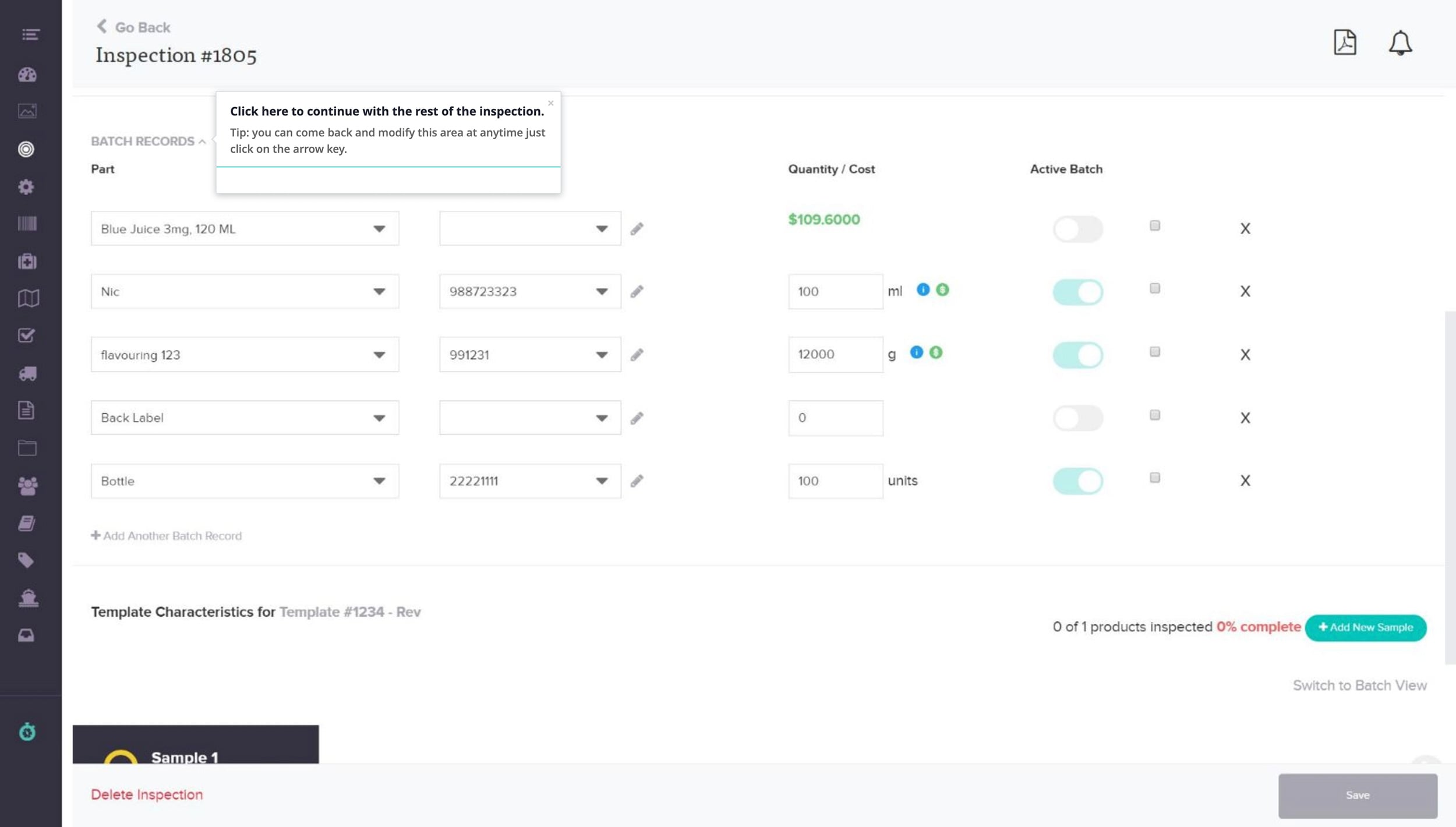

Step 37

Click here to continue with the rest of the inspection.

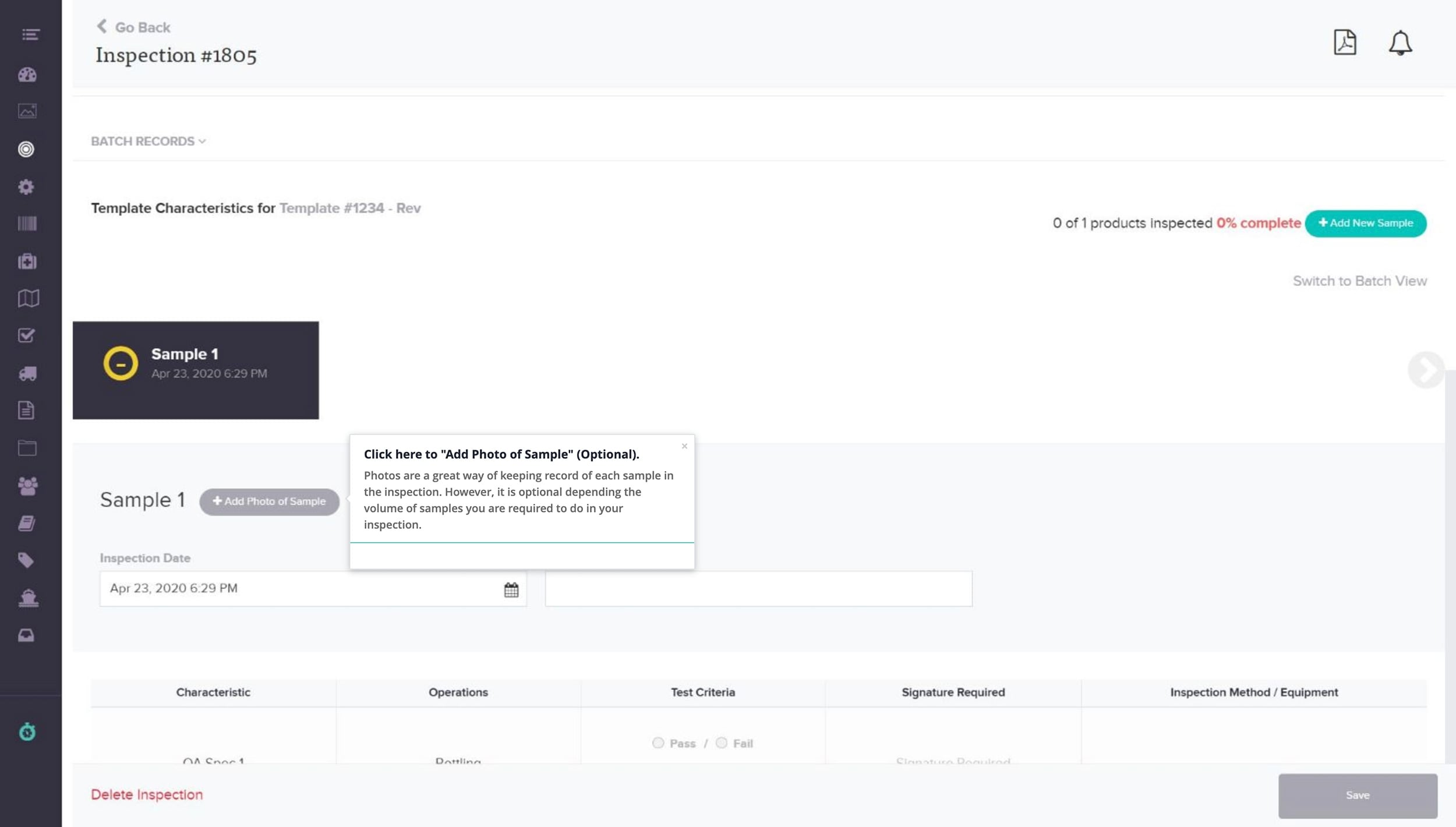

Step 38

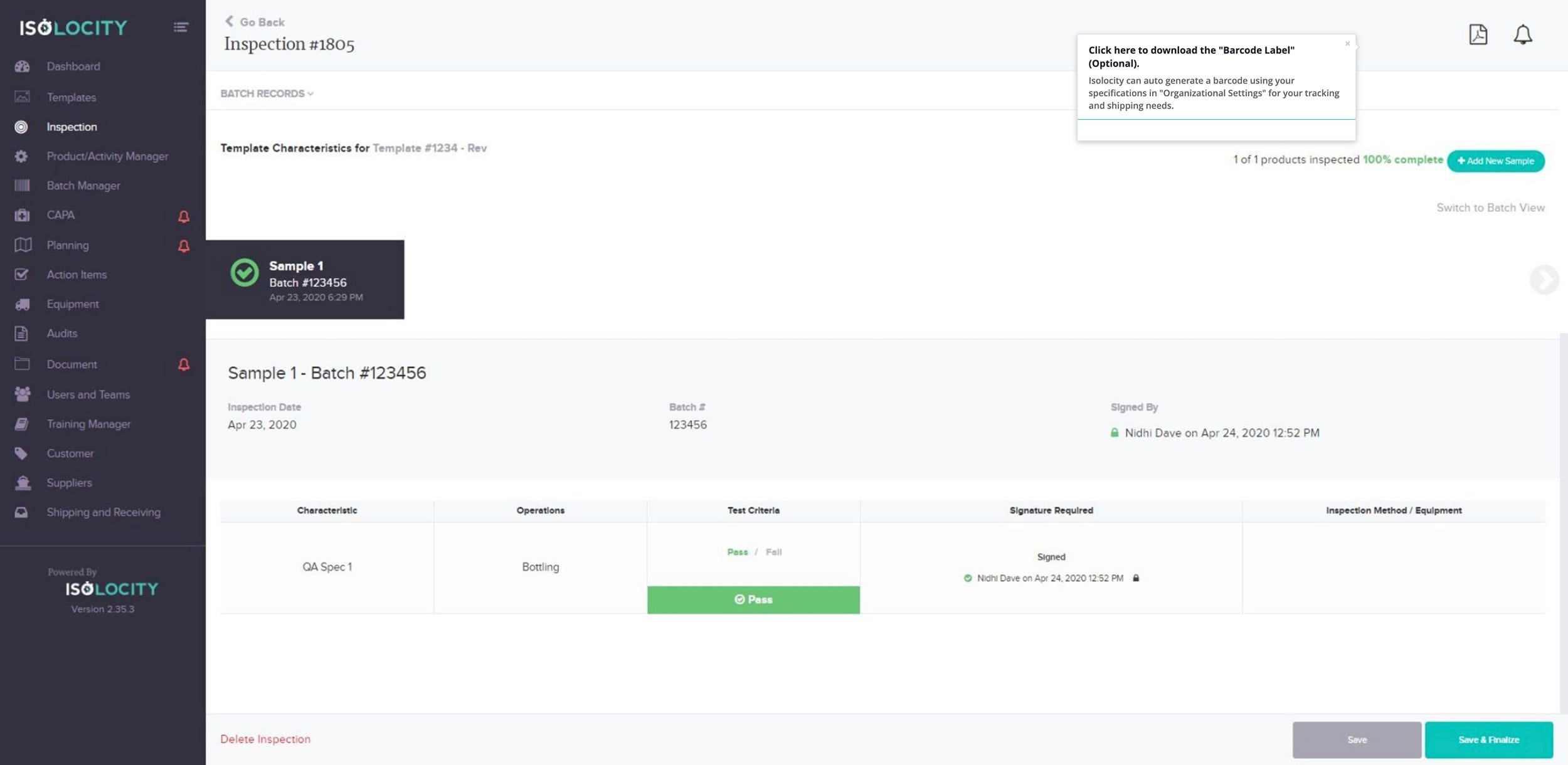

Click here to “Add Photo of Sample” (Optional).

Step 39

Select the date of the inspection.

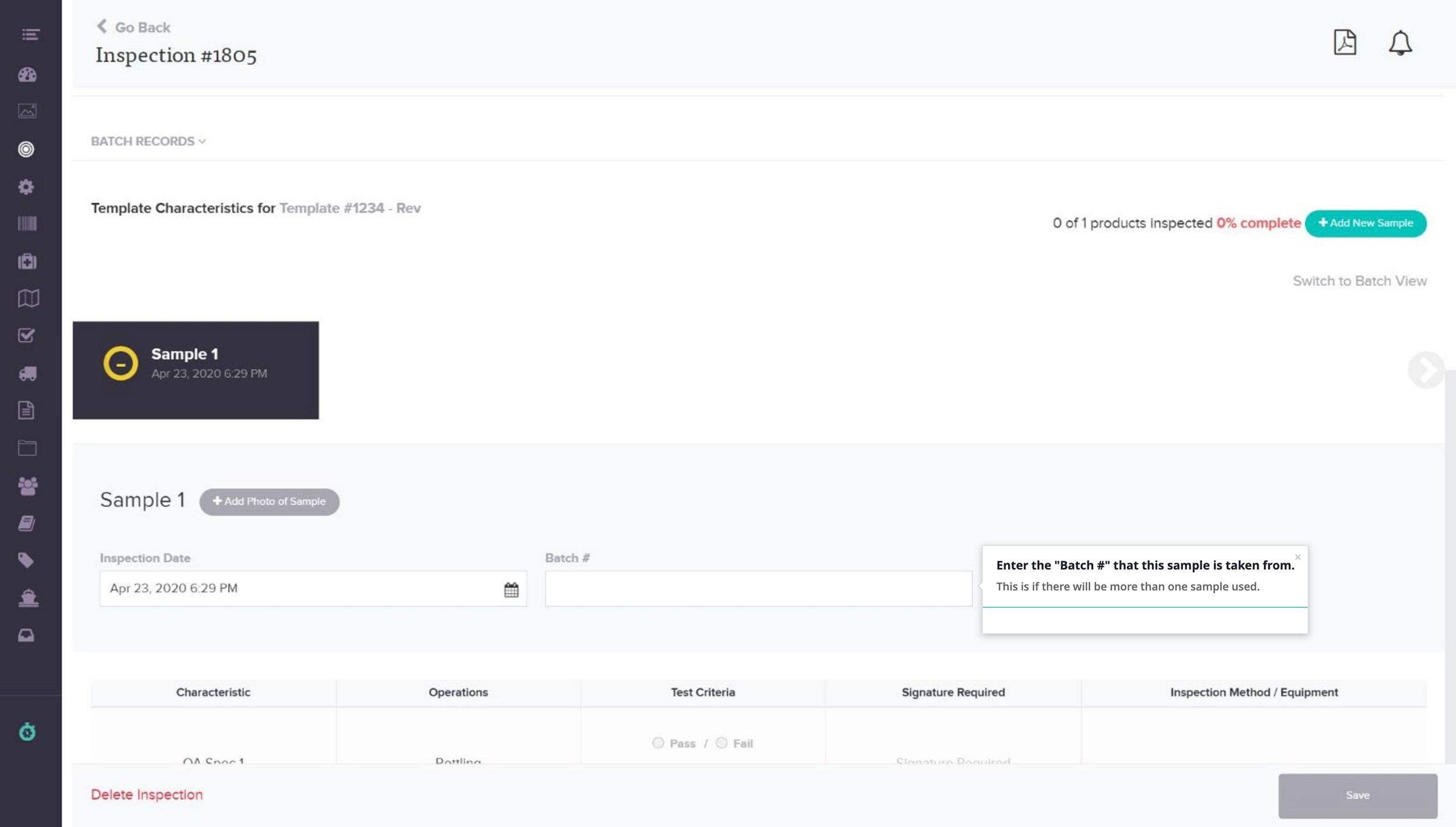

Step 40

Enter the “Batch #” that this sample is taken from.

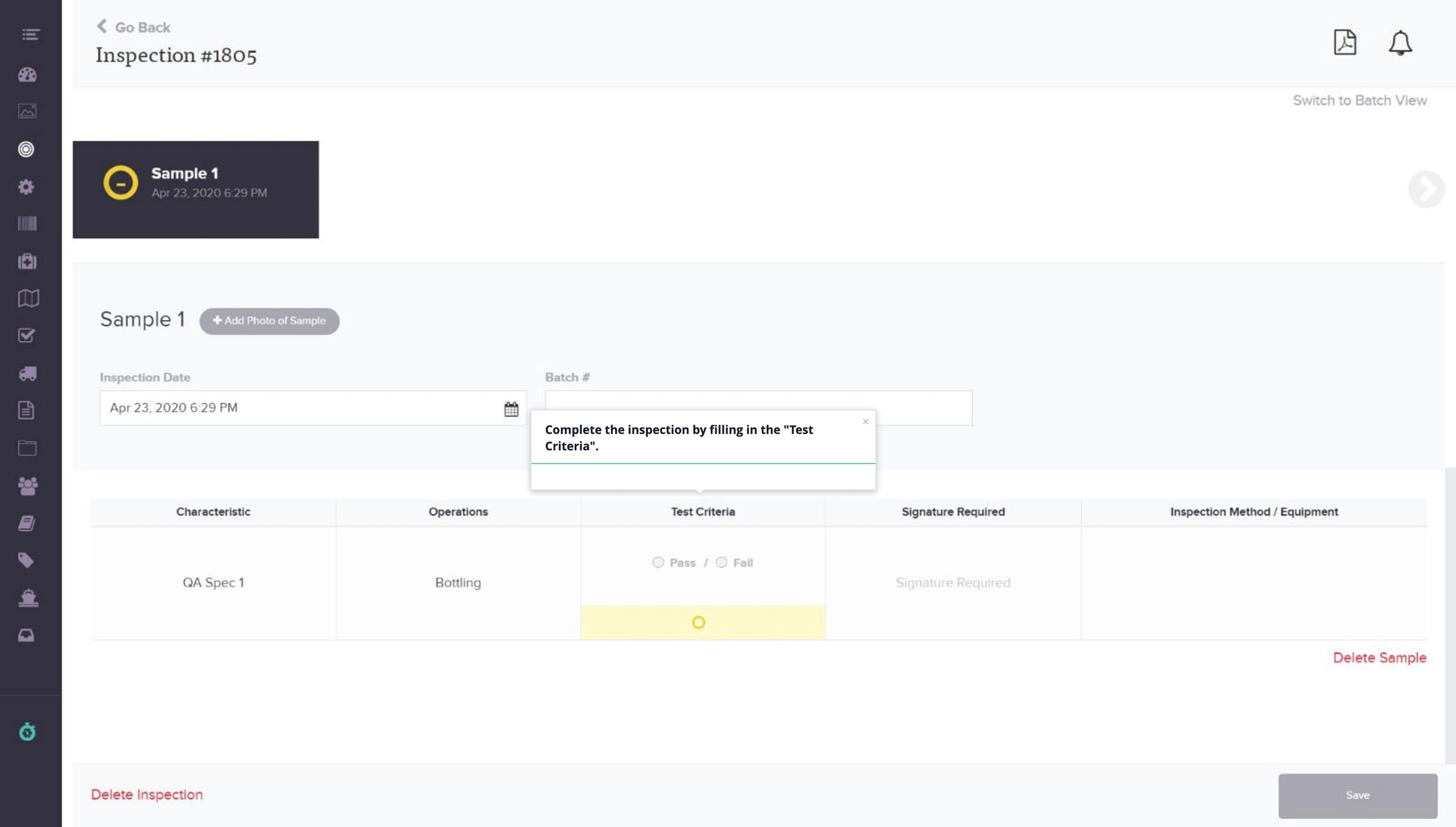

Step 41

Complete the inspection by filling in the “Test Criteria”.

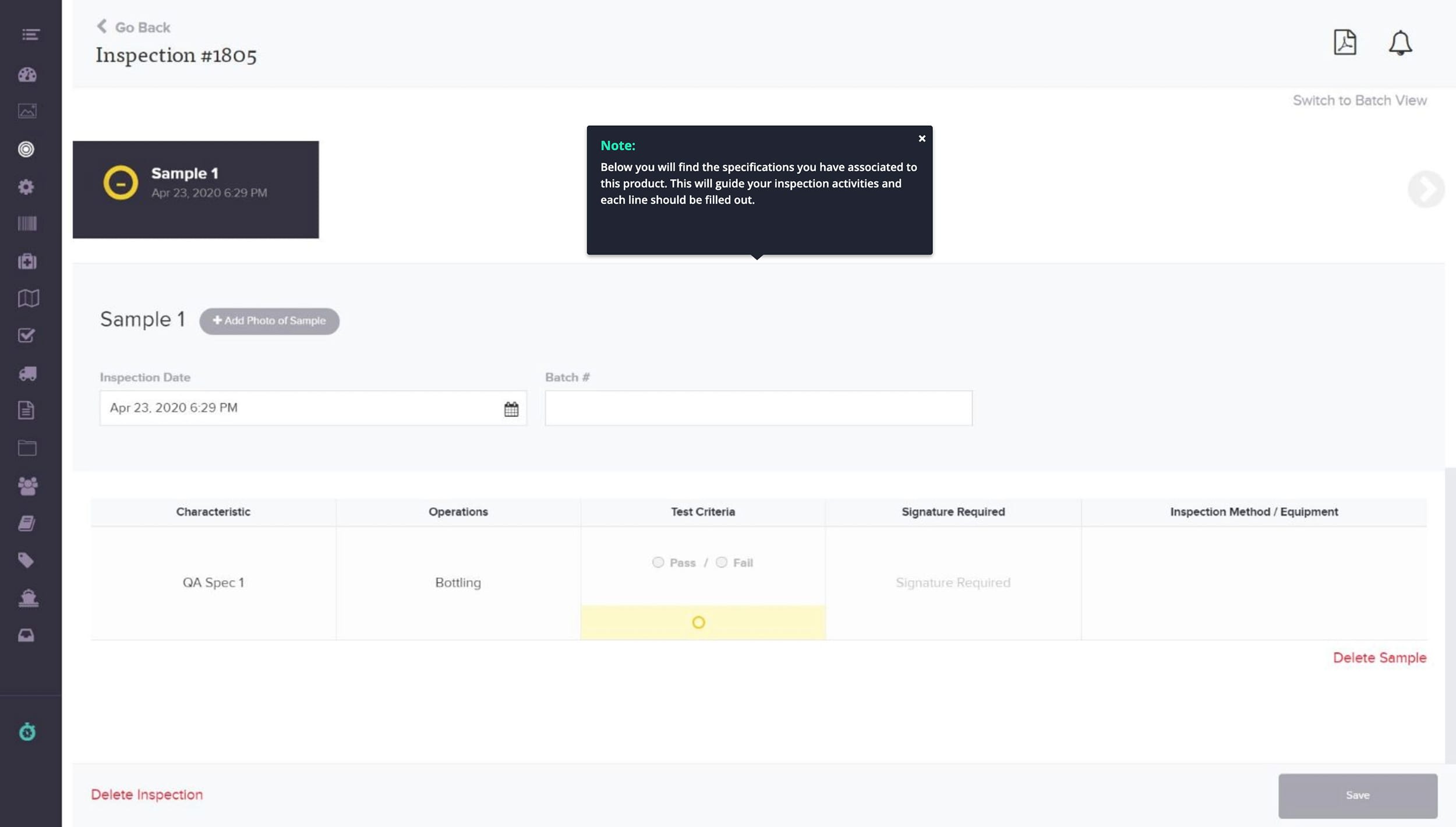

Step 42

Note:

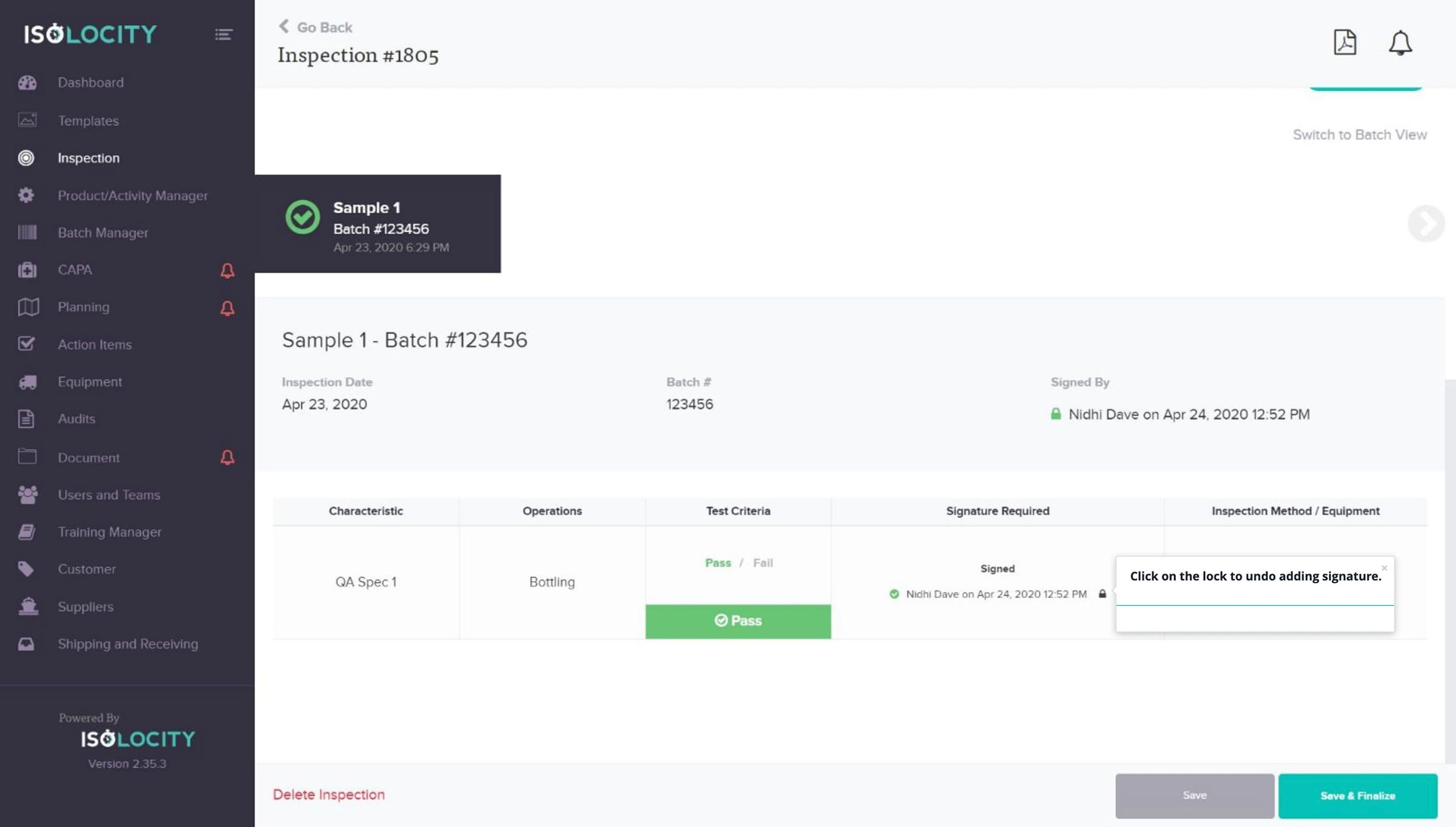

Step 43

Click on the lock to undo adding signature.

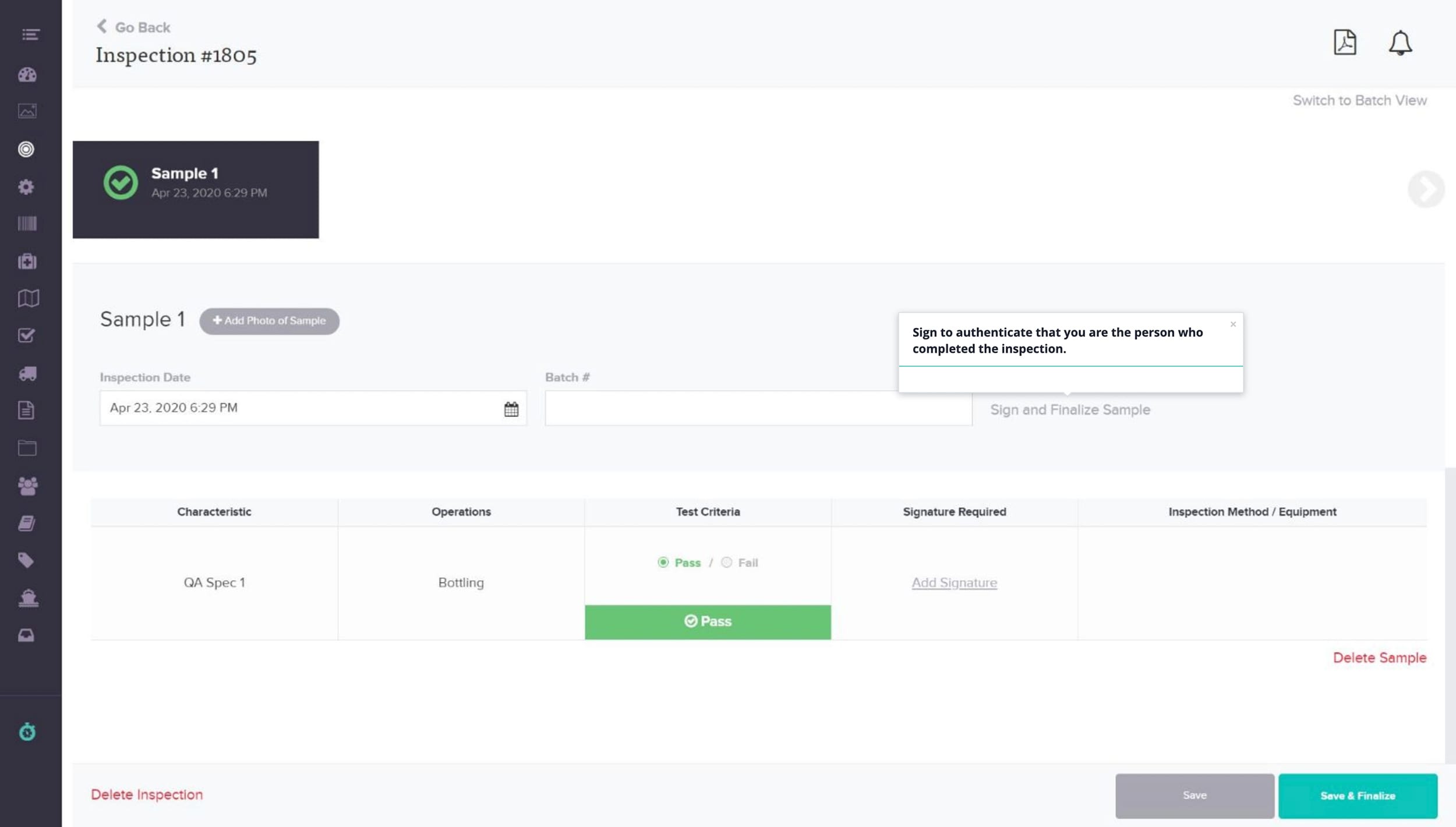

Step 44

Sign to authenticate that you are the person who completed the inspection.

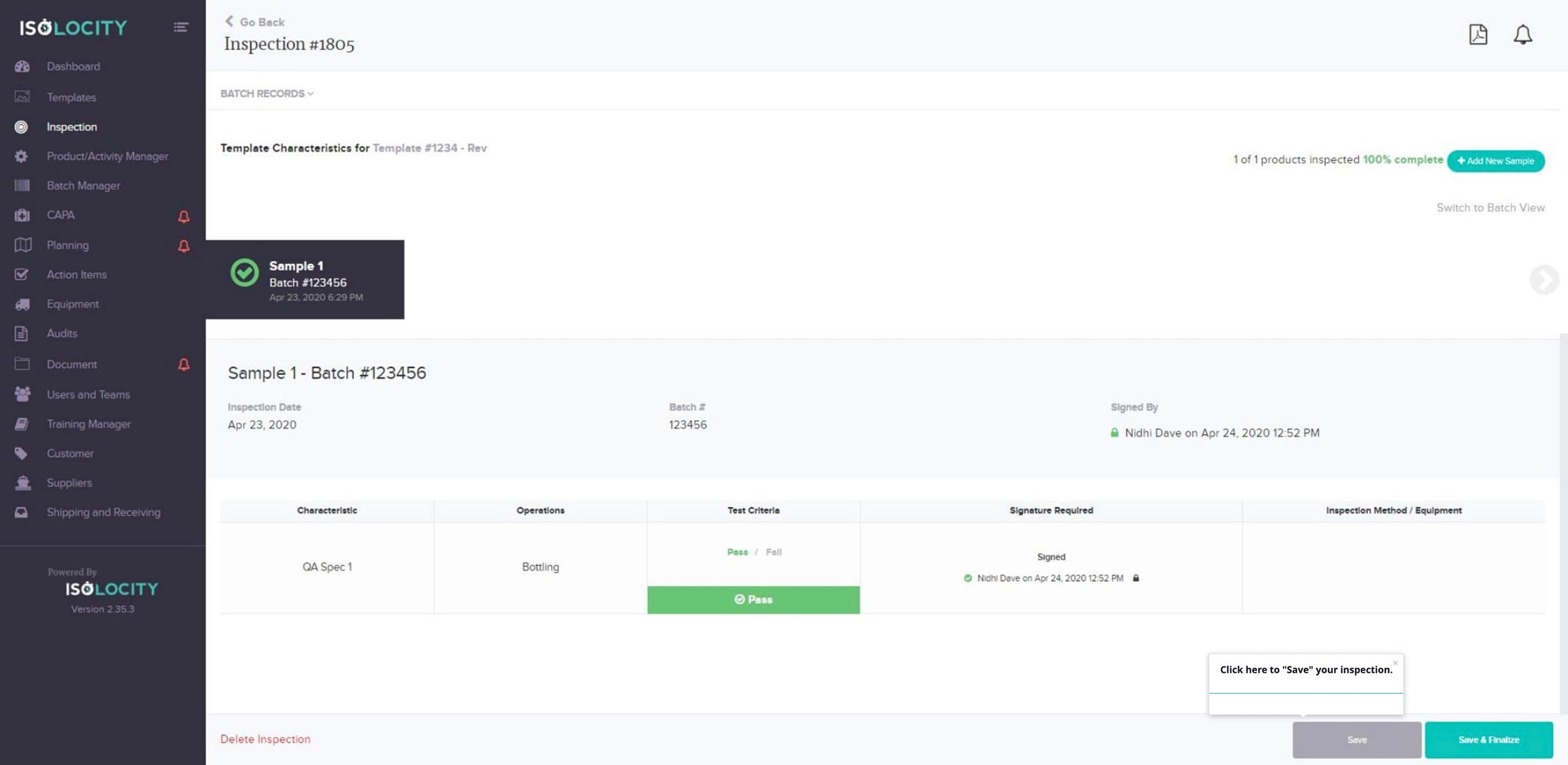

Step 45

Click here to “Save” your inspection.

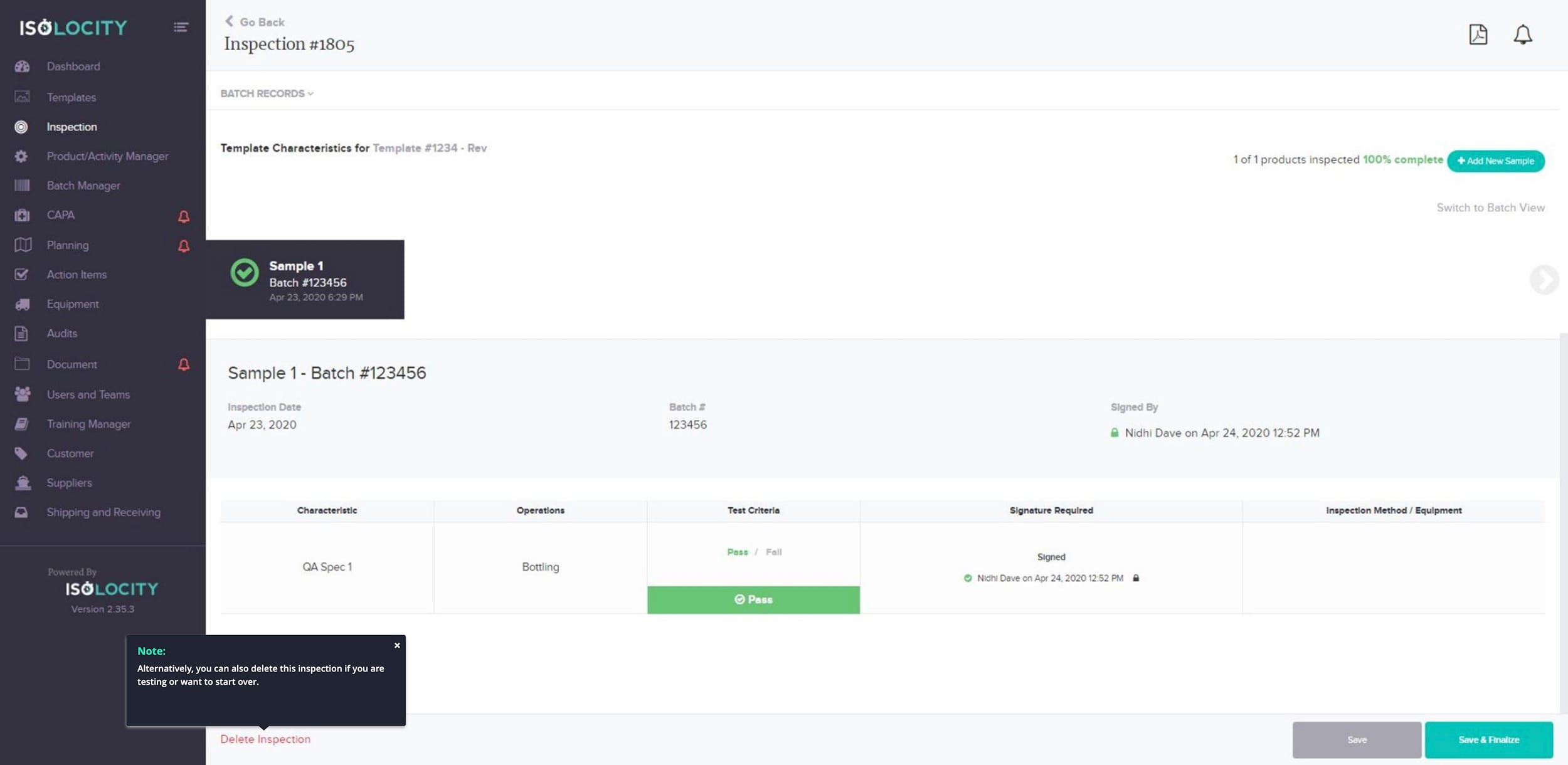

Step 46

Note:

Step 47

If the product Inspection has failed, it is possible to Initiate a Corrective Action Report or a Non-Conformance Report or an OOS Report.

Step 48

Click the PDF icon

Step 49

Click here to download the “Barcode Label” (Optional).

Step 50

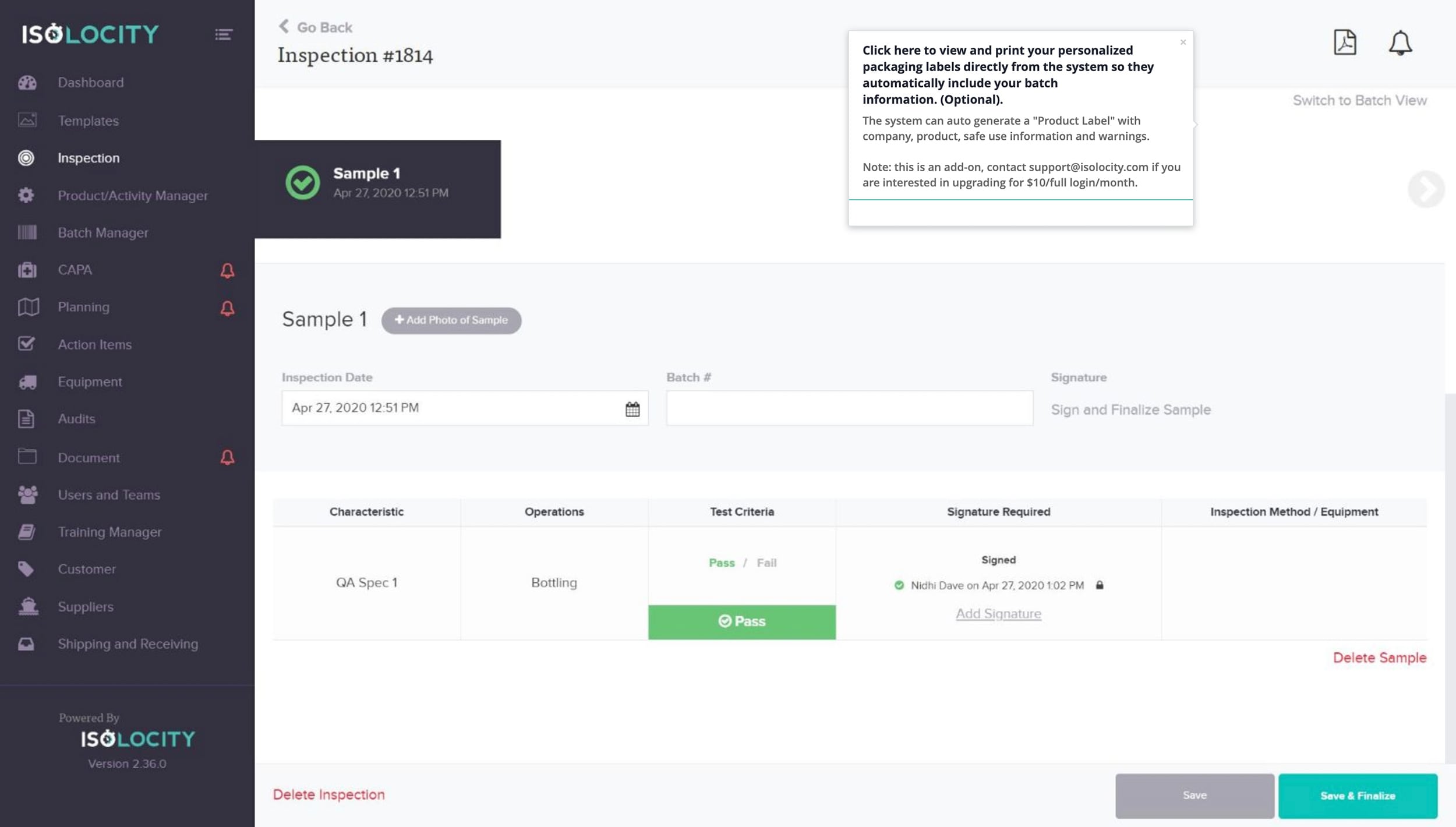

Note:

Step 51

Click here to view and print your personalized packaging labels directly from the system so they automatically include your batch information. (Optional).

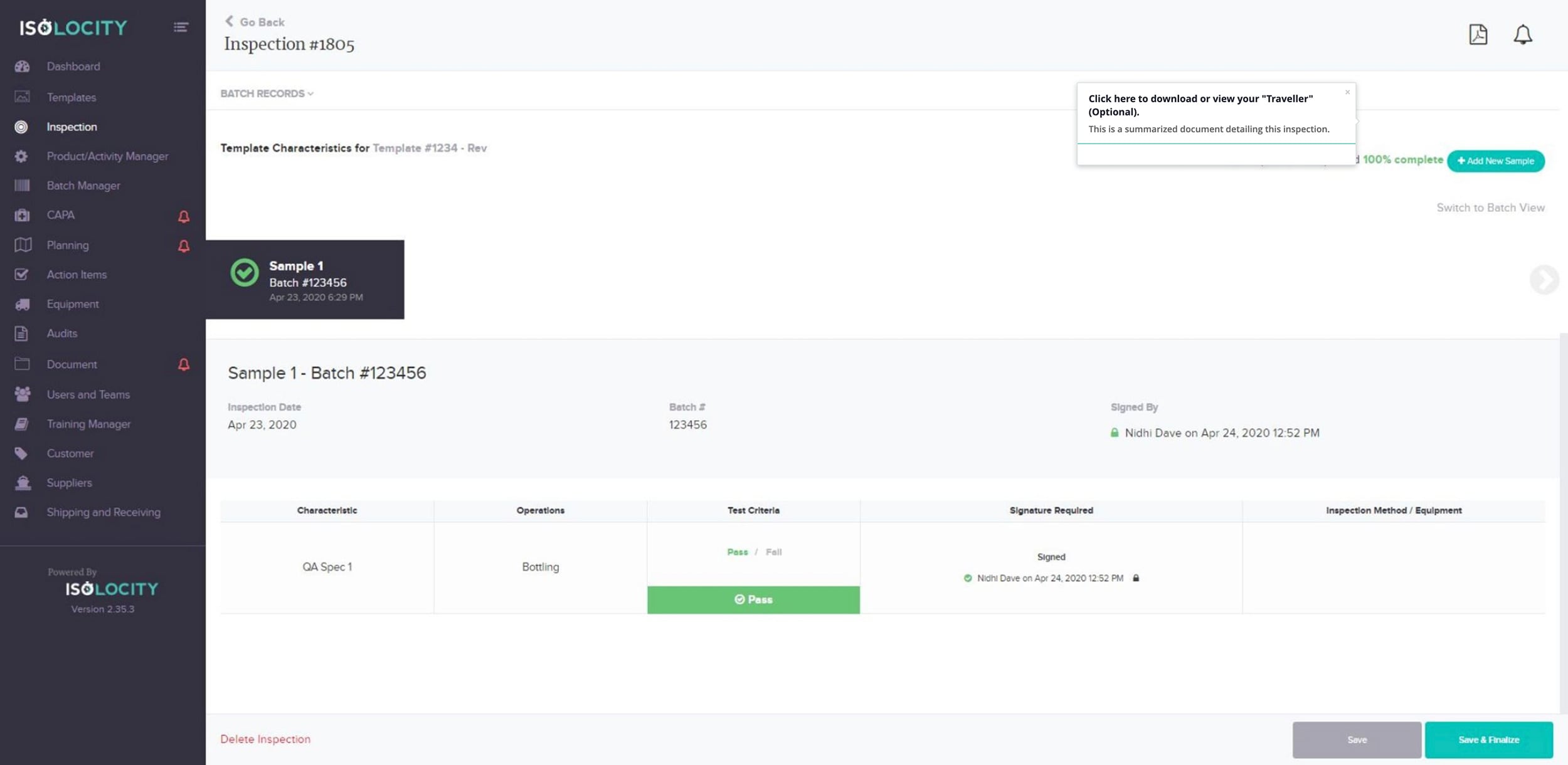

Step 52

Click here to download or view your “Traveller” (Optional).

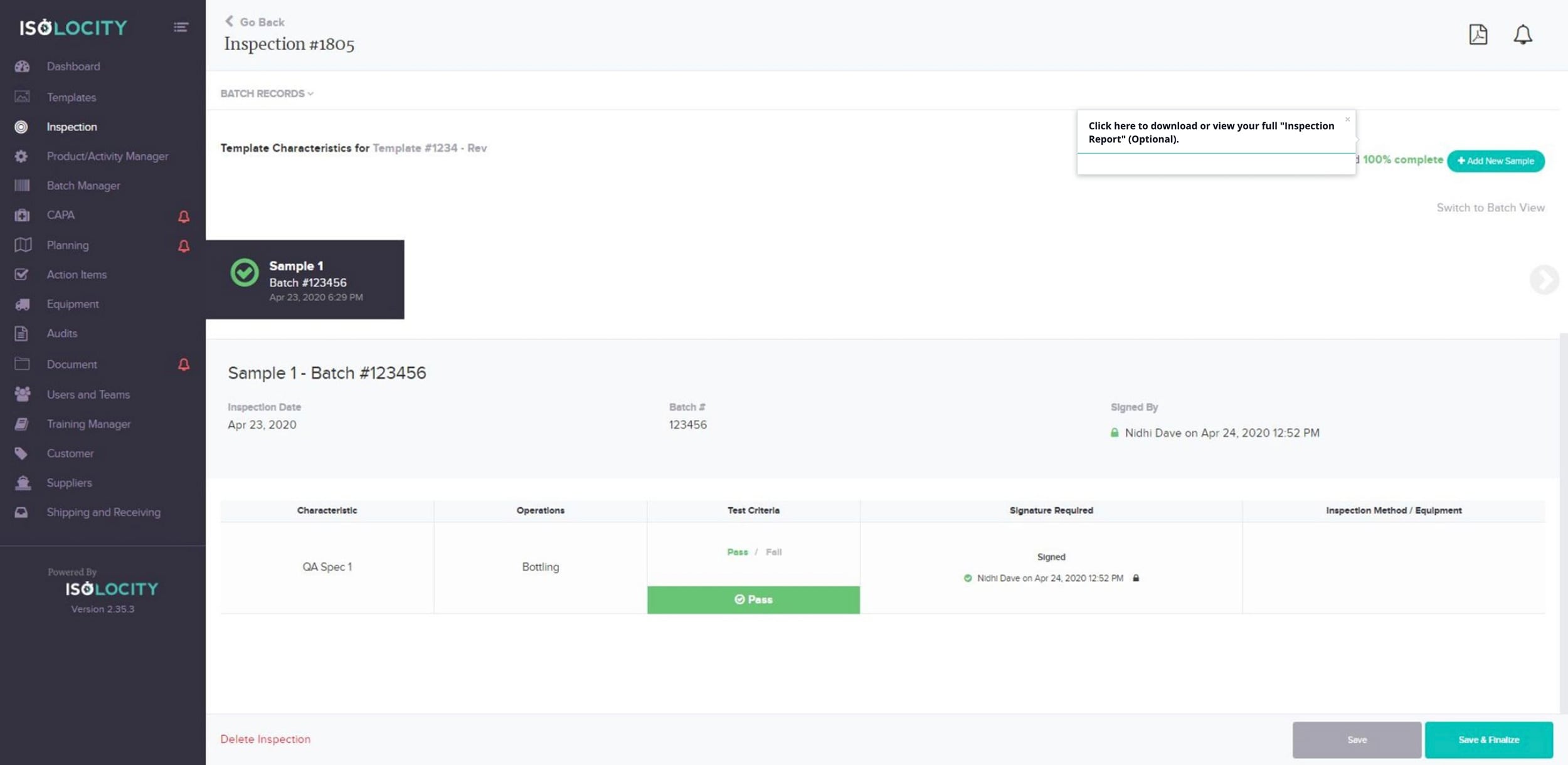

Step 53

Click here to download or view your full “Inspection Report” (Optional).

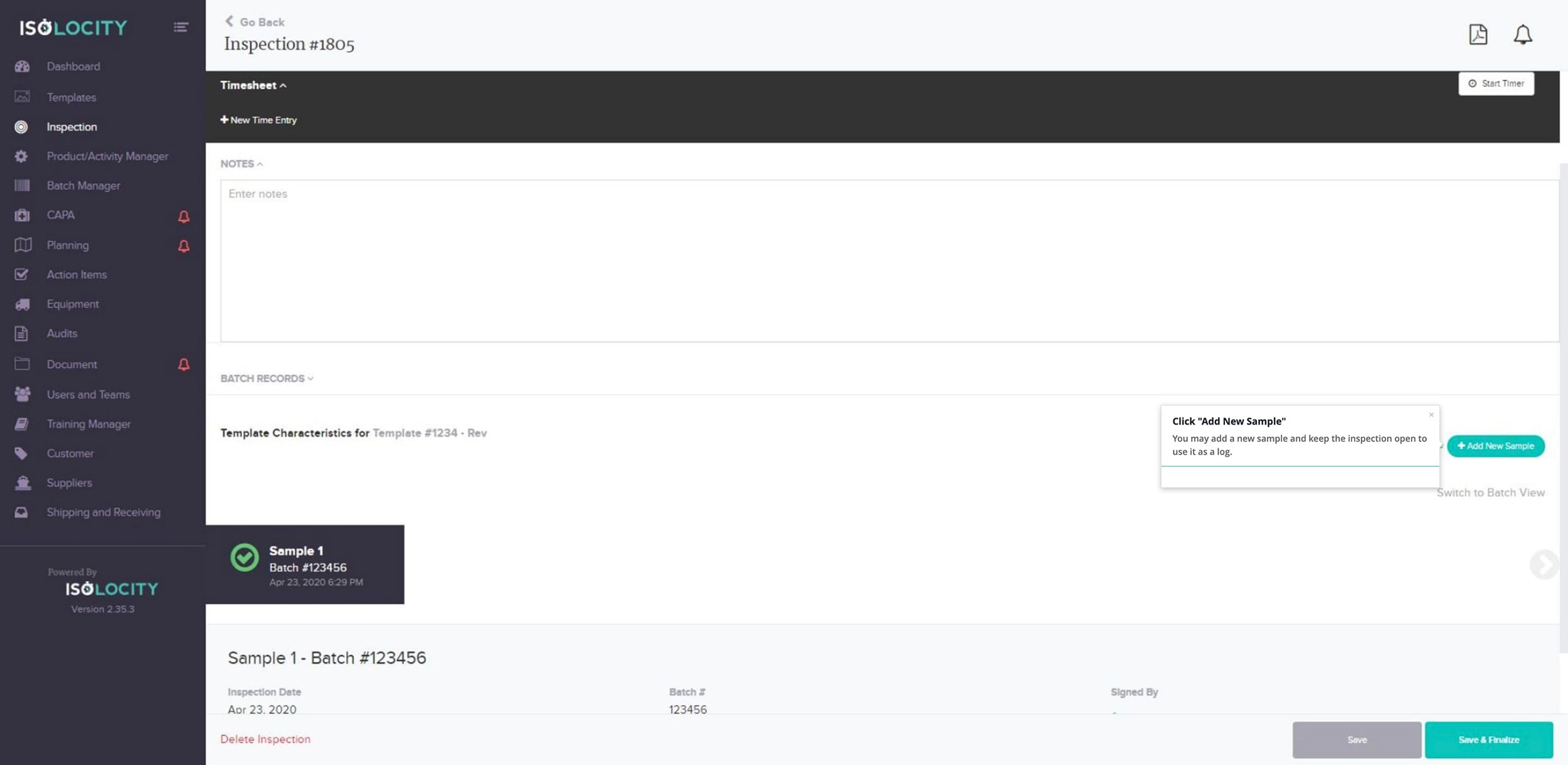

Step 54

Click “Add New Sample”

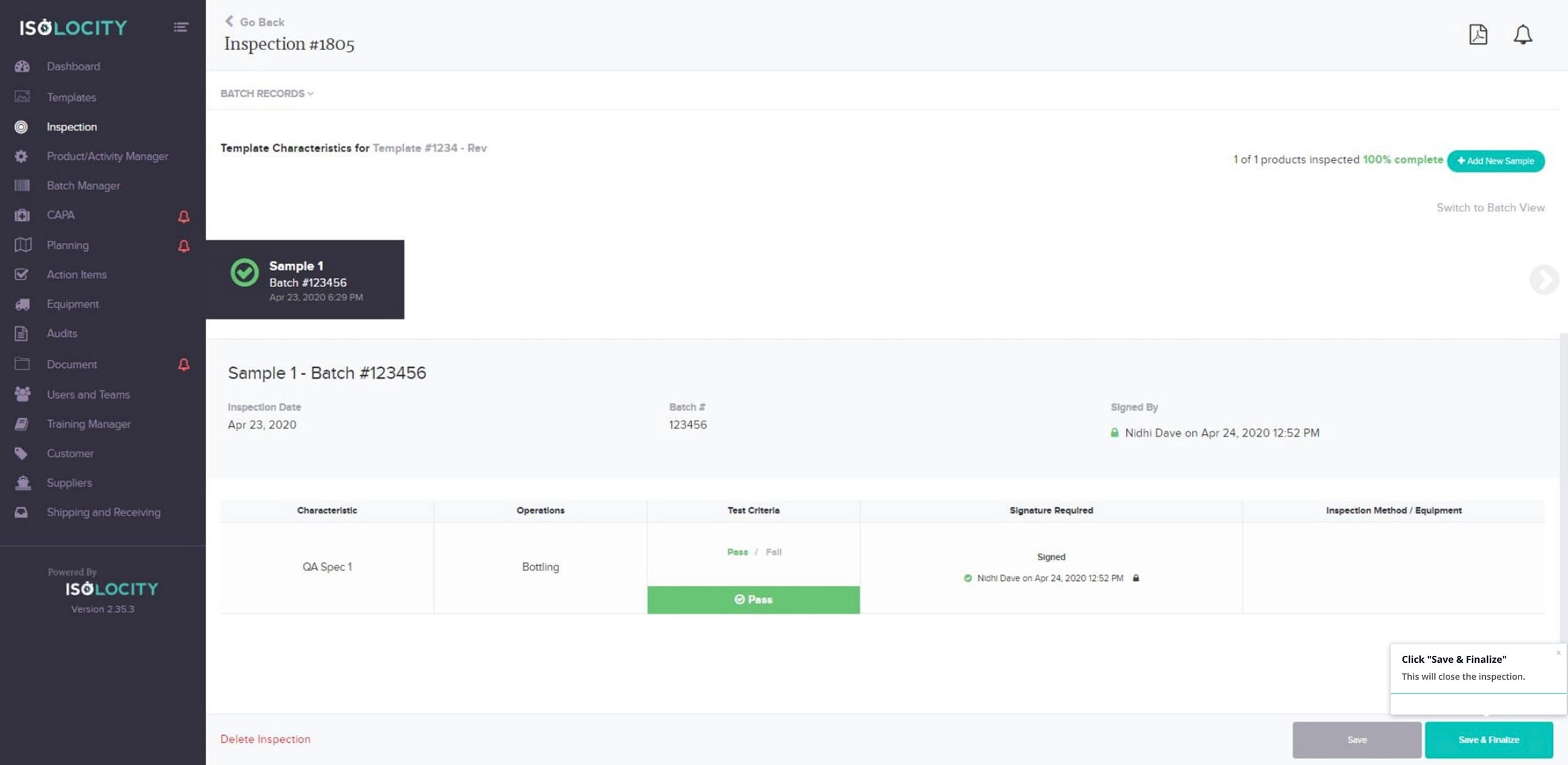

Step 55

Click “Save & Finalize”

Step 56

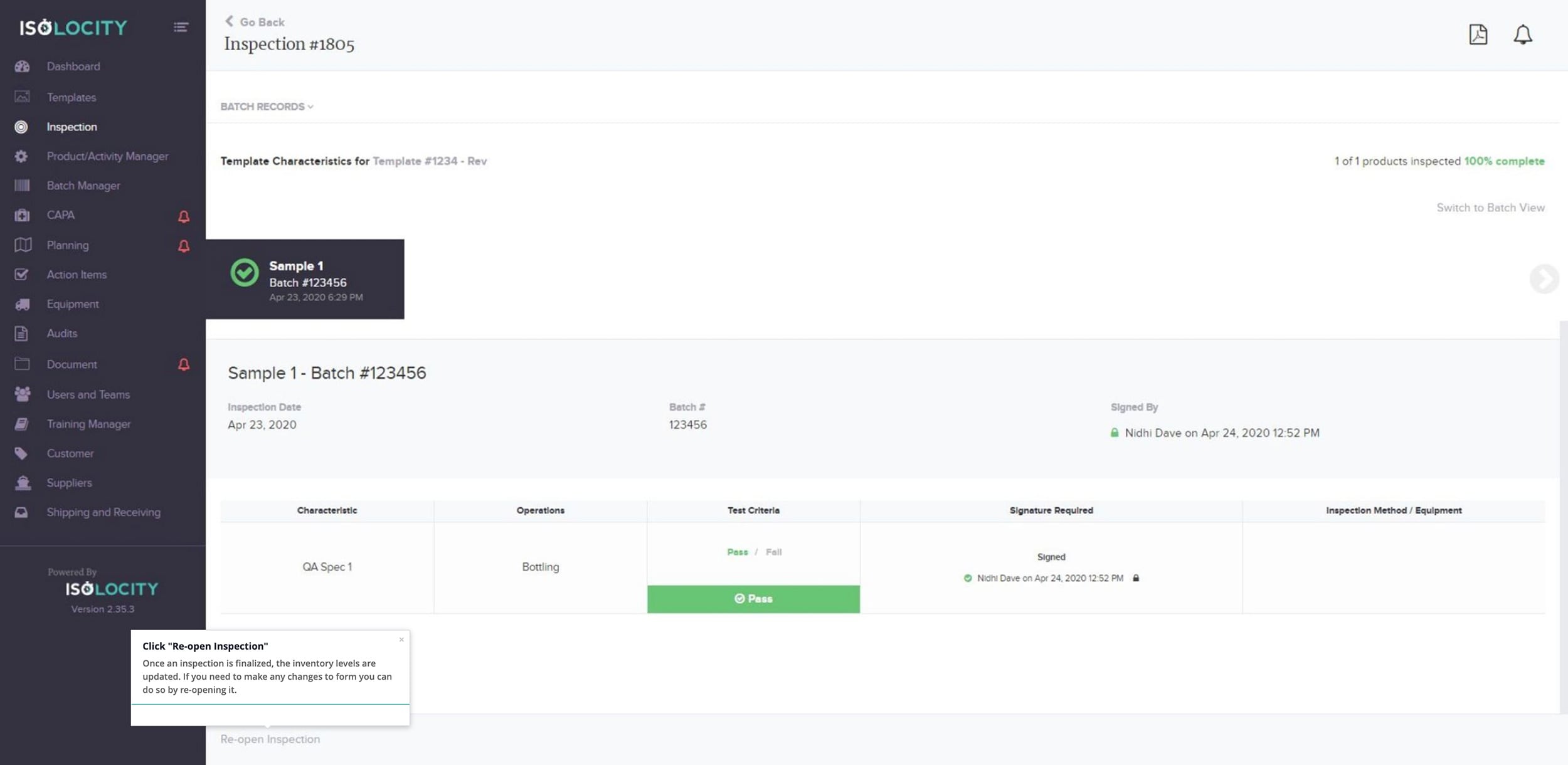

Click “Re-open Inspection”

Step 57

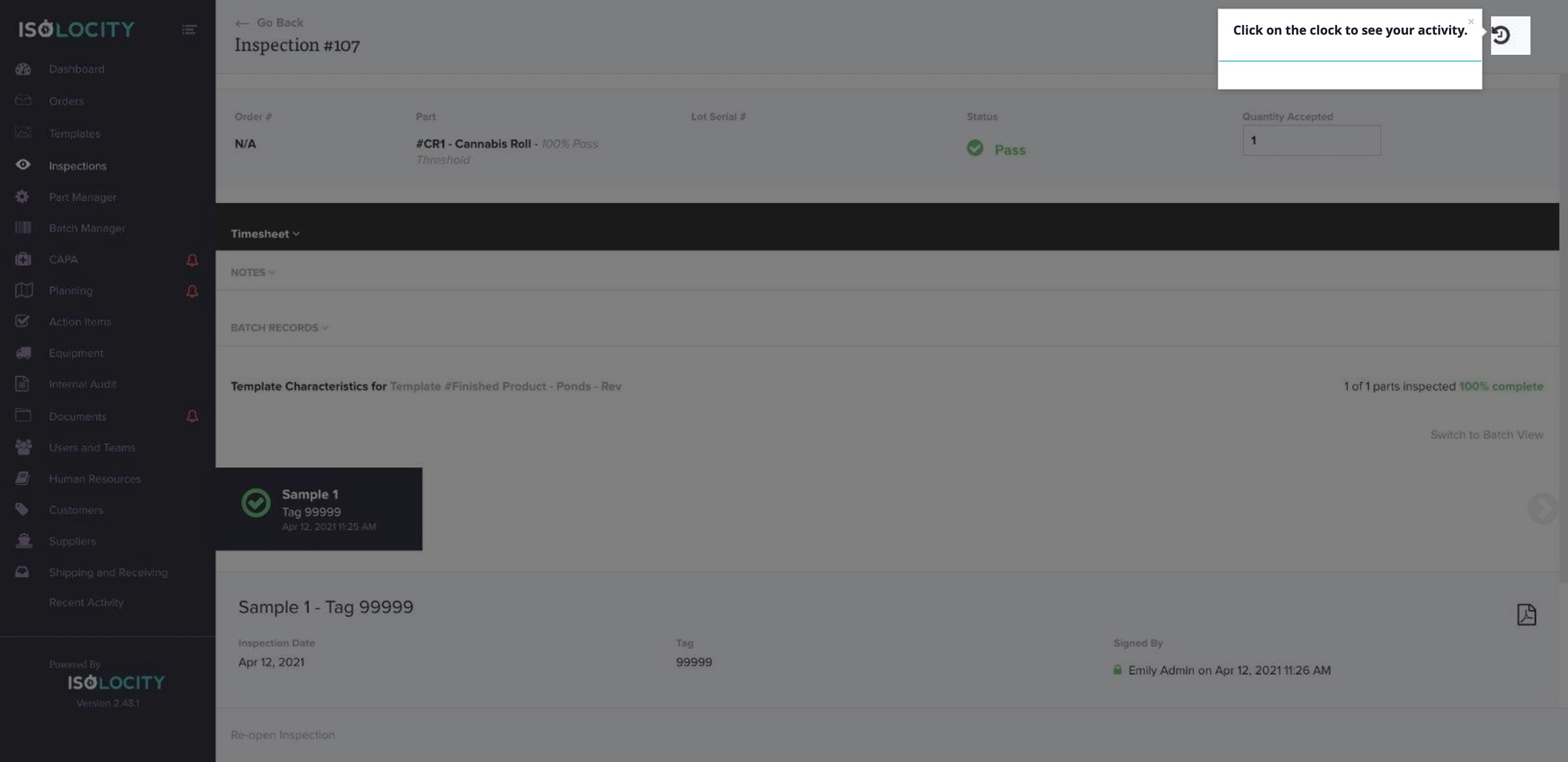

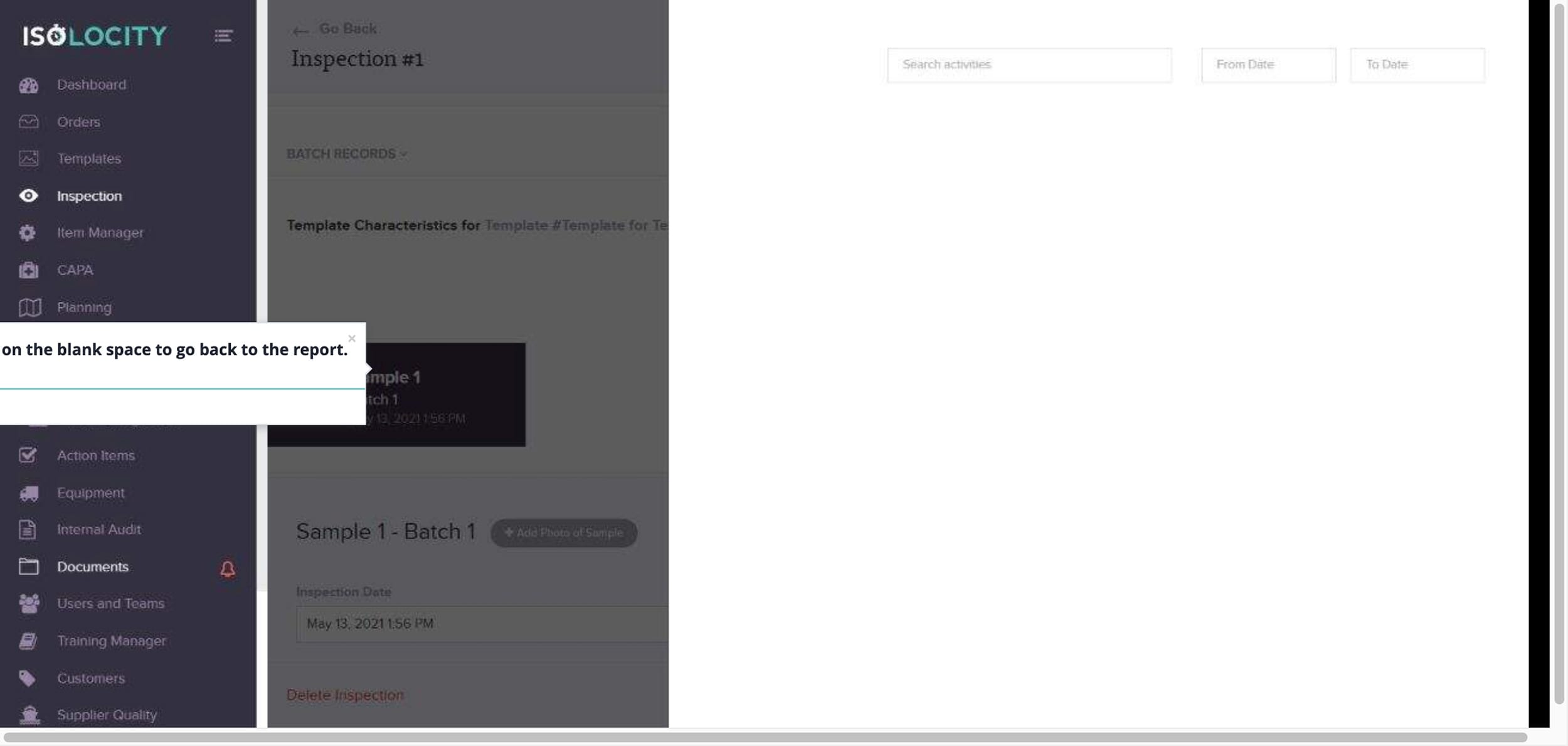

Click on the clock to see your activity.

Step 58

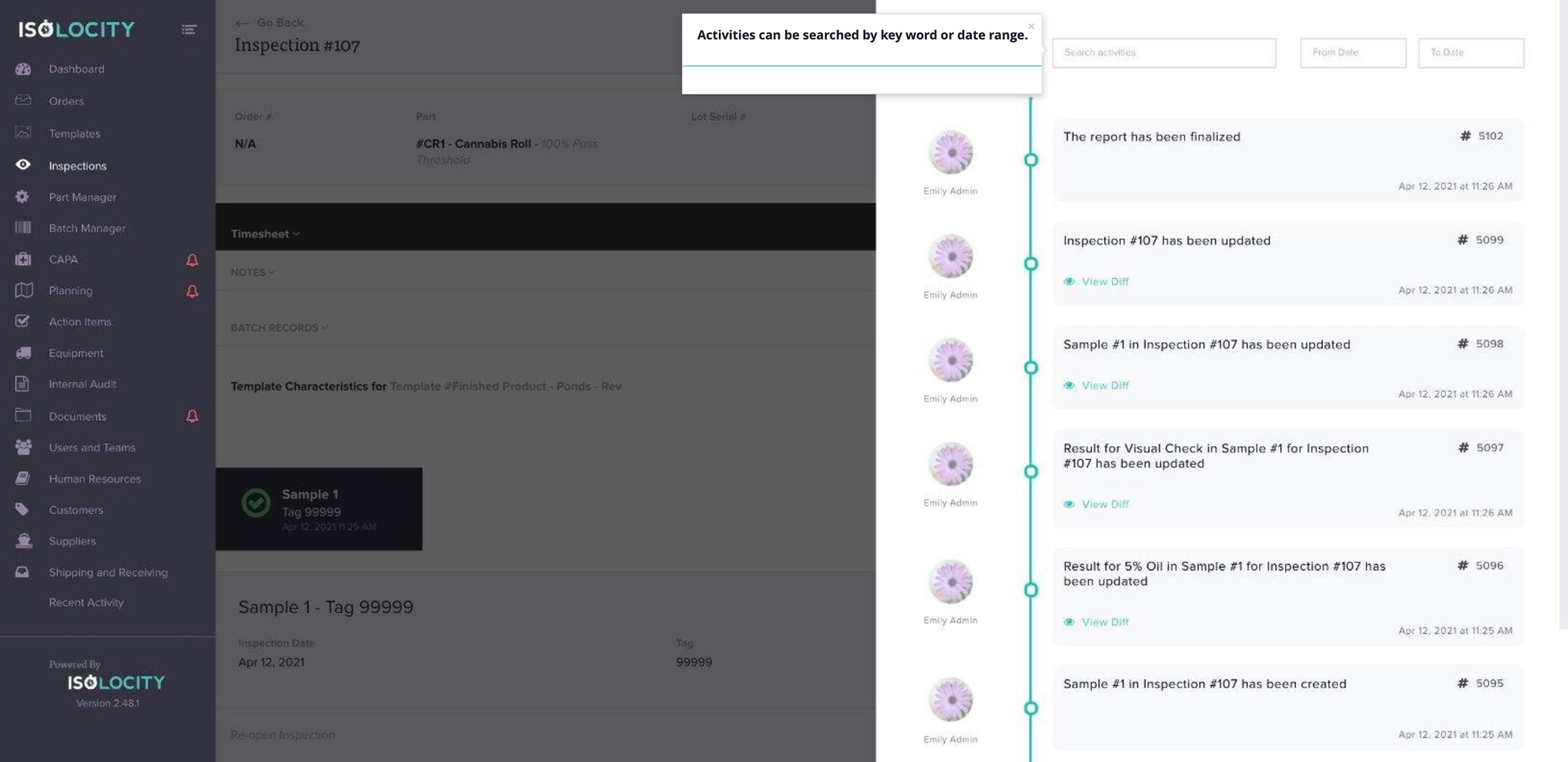

The activity tracker shows all activity for this report.

Step 59

Activities can be searched by key word or date range.

Step 60

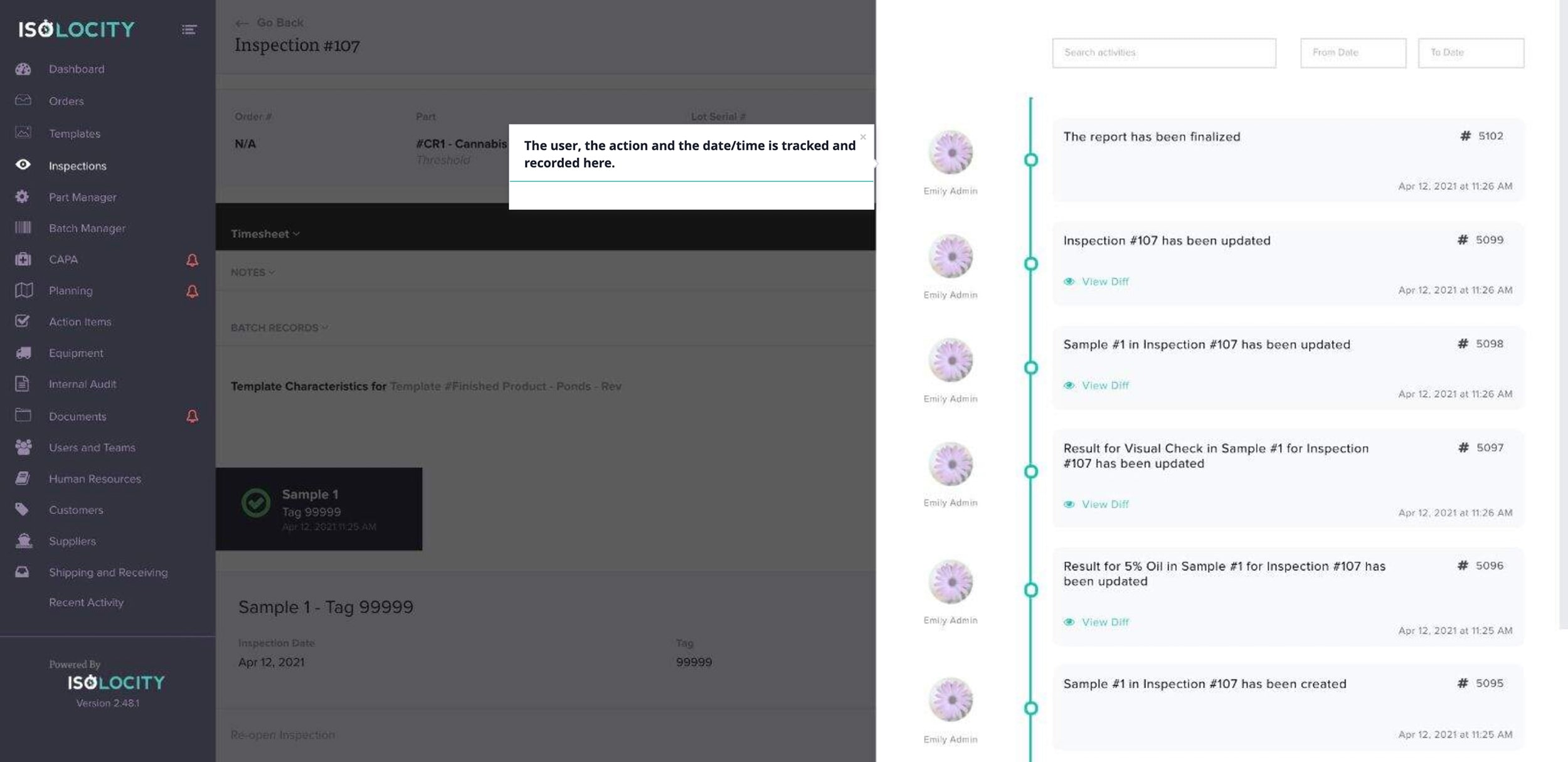

The user, the action and the date/time is tracked and recorded here.

Step 61

Click on the blank space to go back to the report.