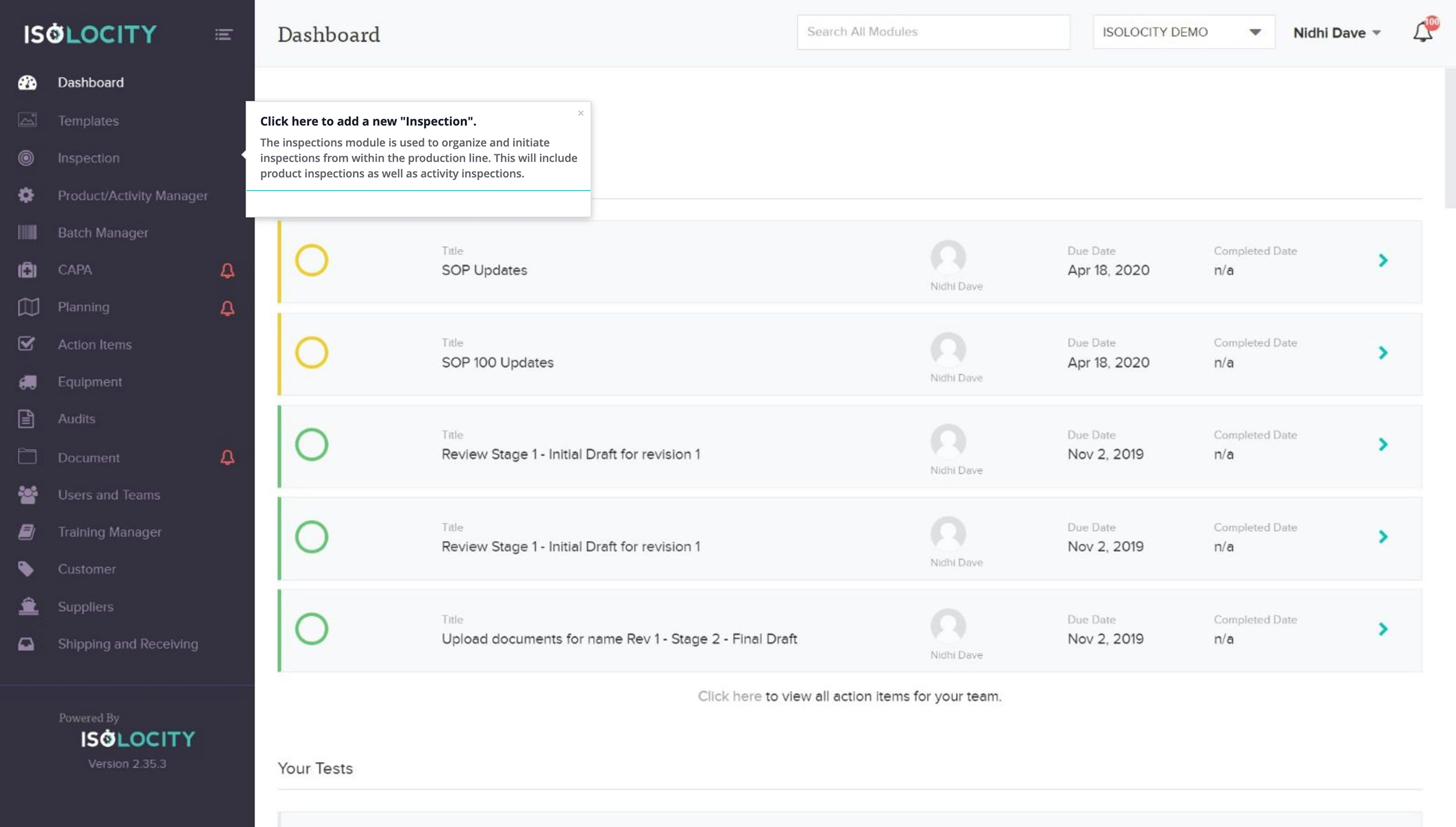

Create A Inspection

Step #1

Click here to add a new “Inspection”.

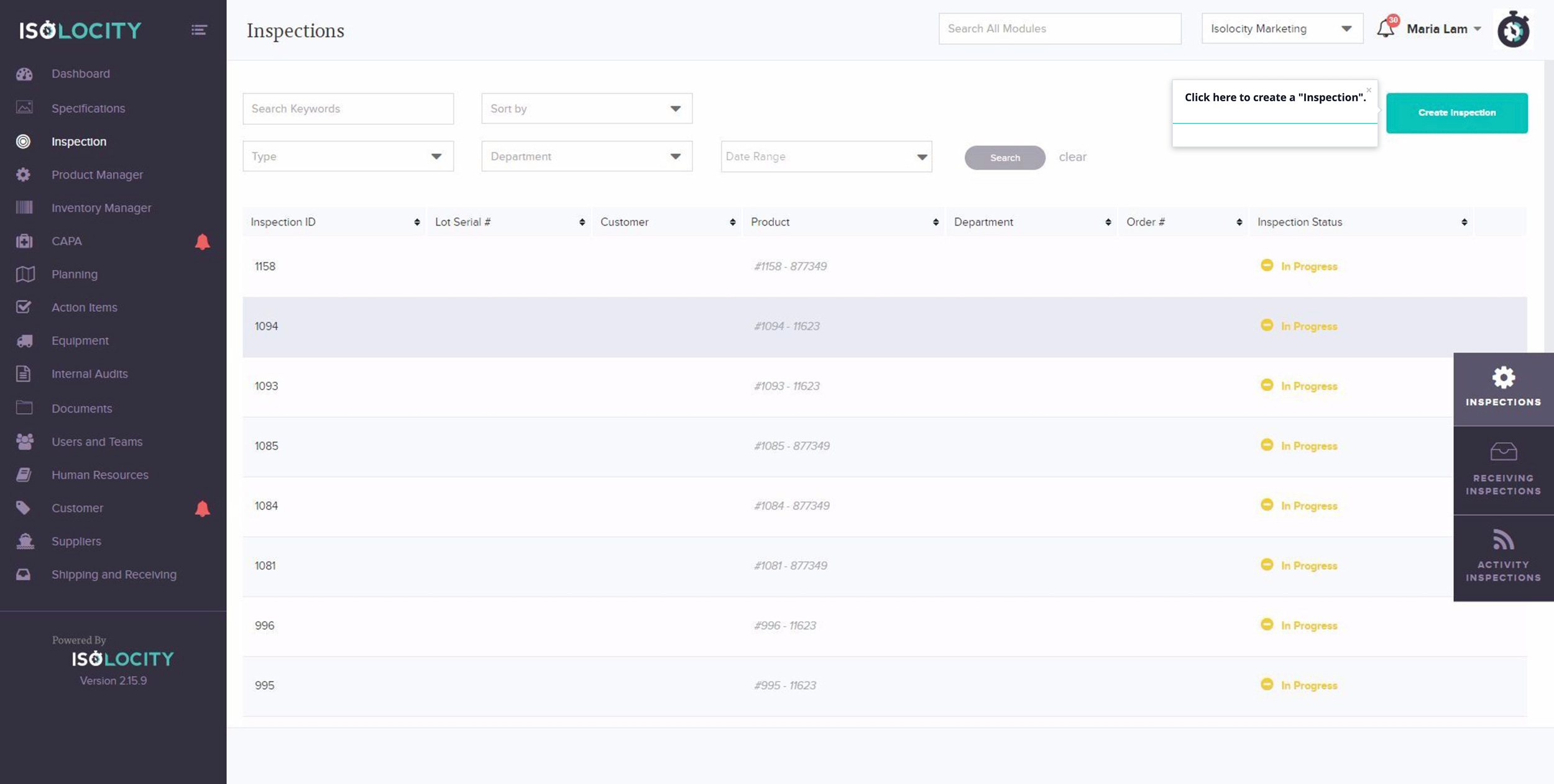

Step #2

Click here to create a “Inspection”.

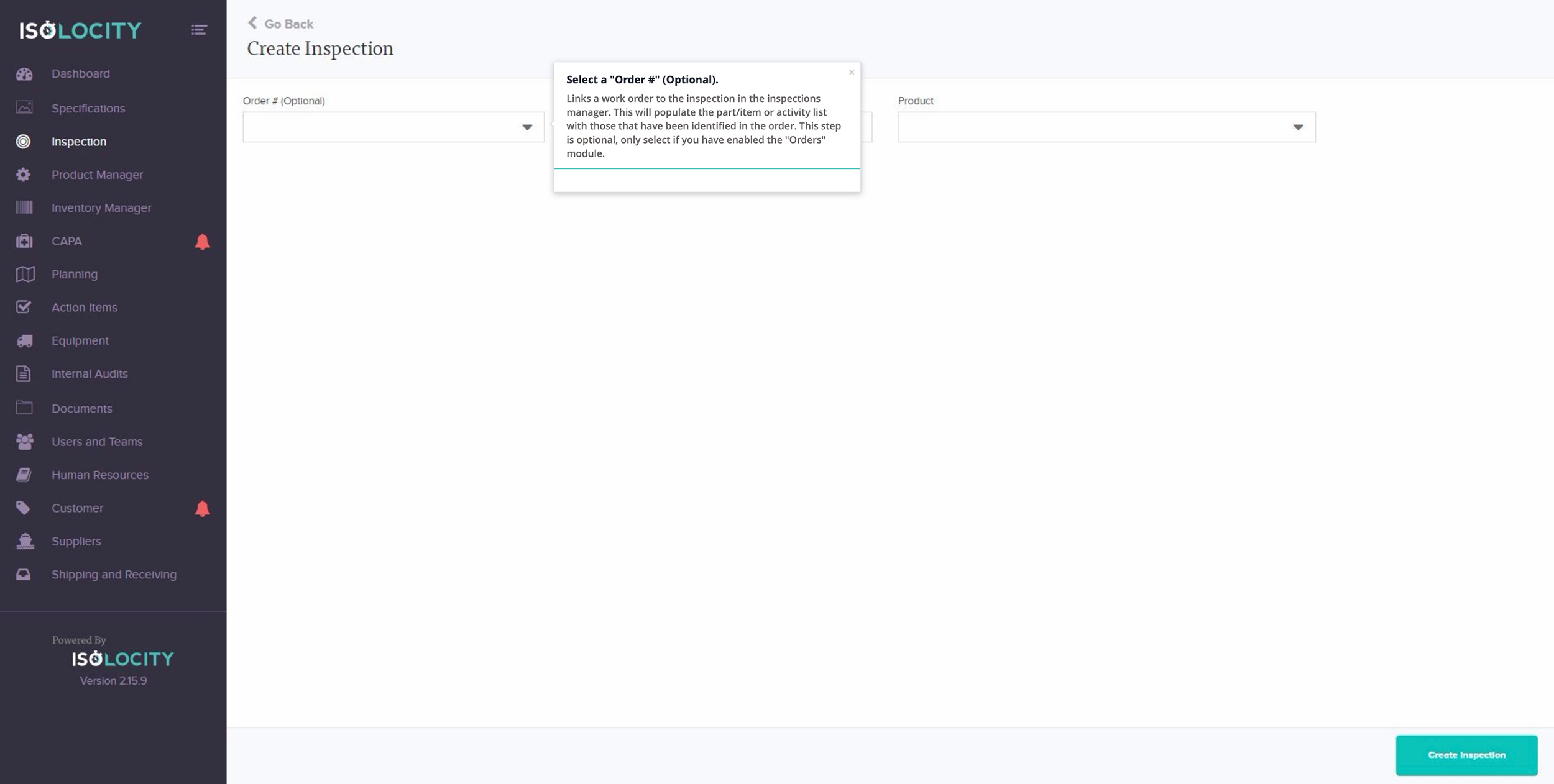

Step #3

Select a “Order #” (Optional).

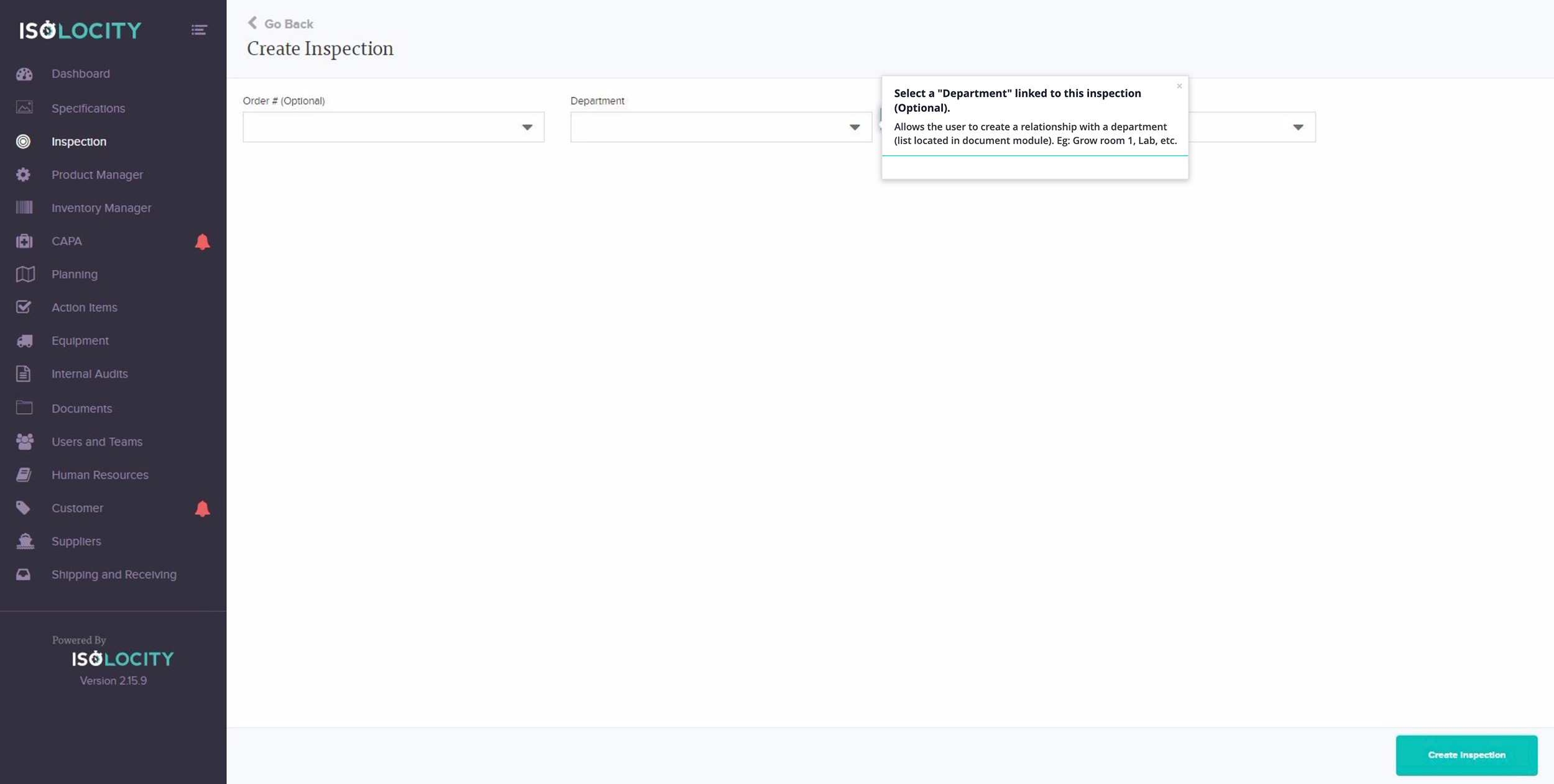

Step #4

Select a “Department” linked to this inspection (Optional).

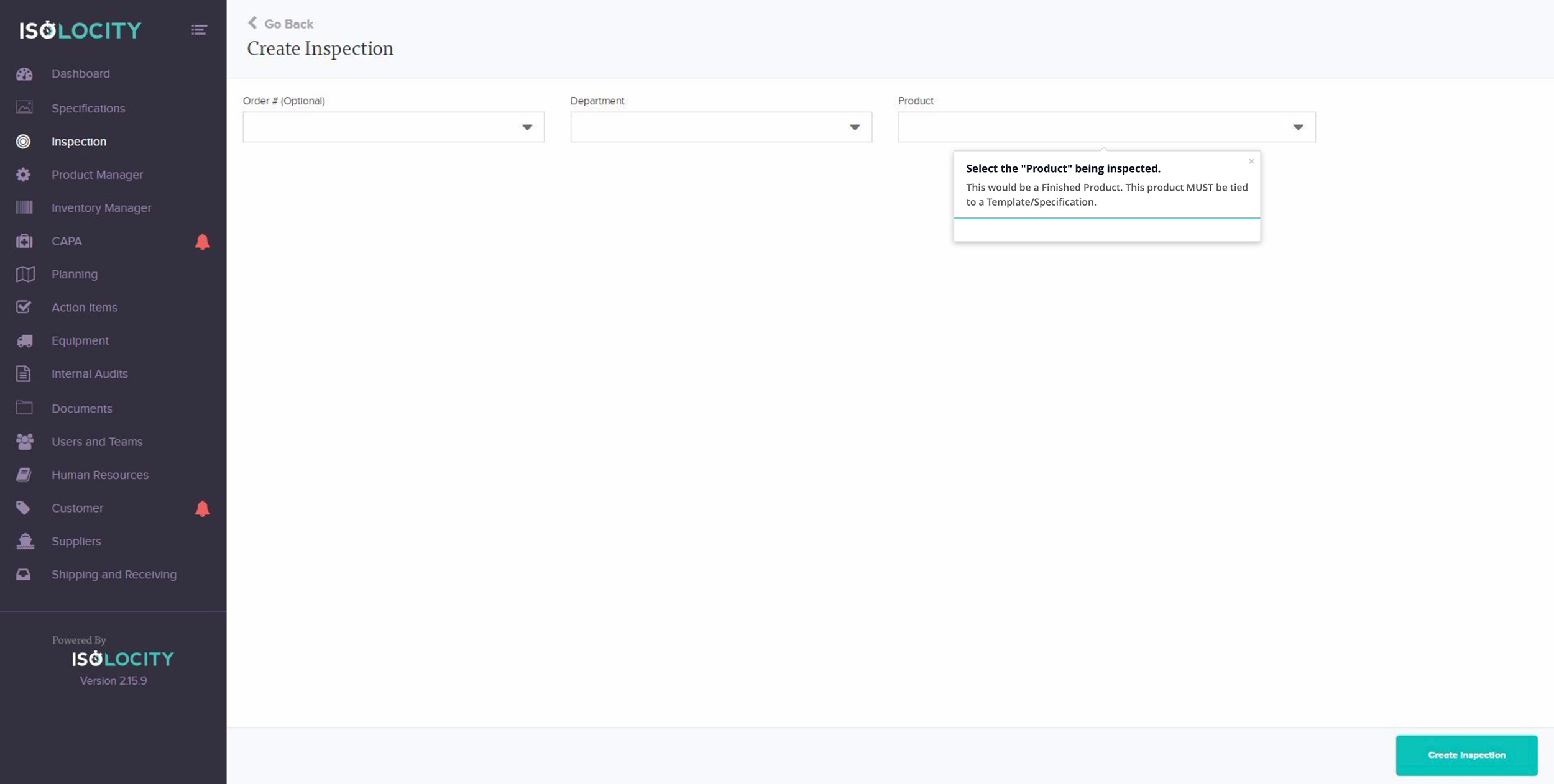

Step #5

Select the “Product” being inspected.

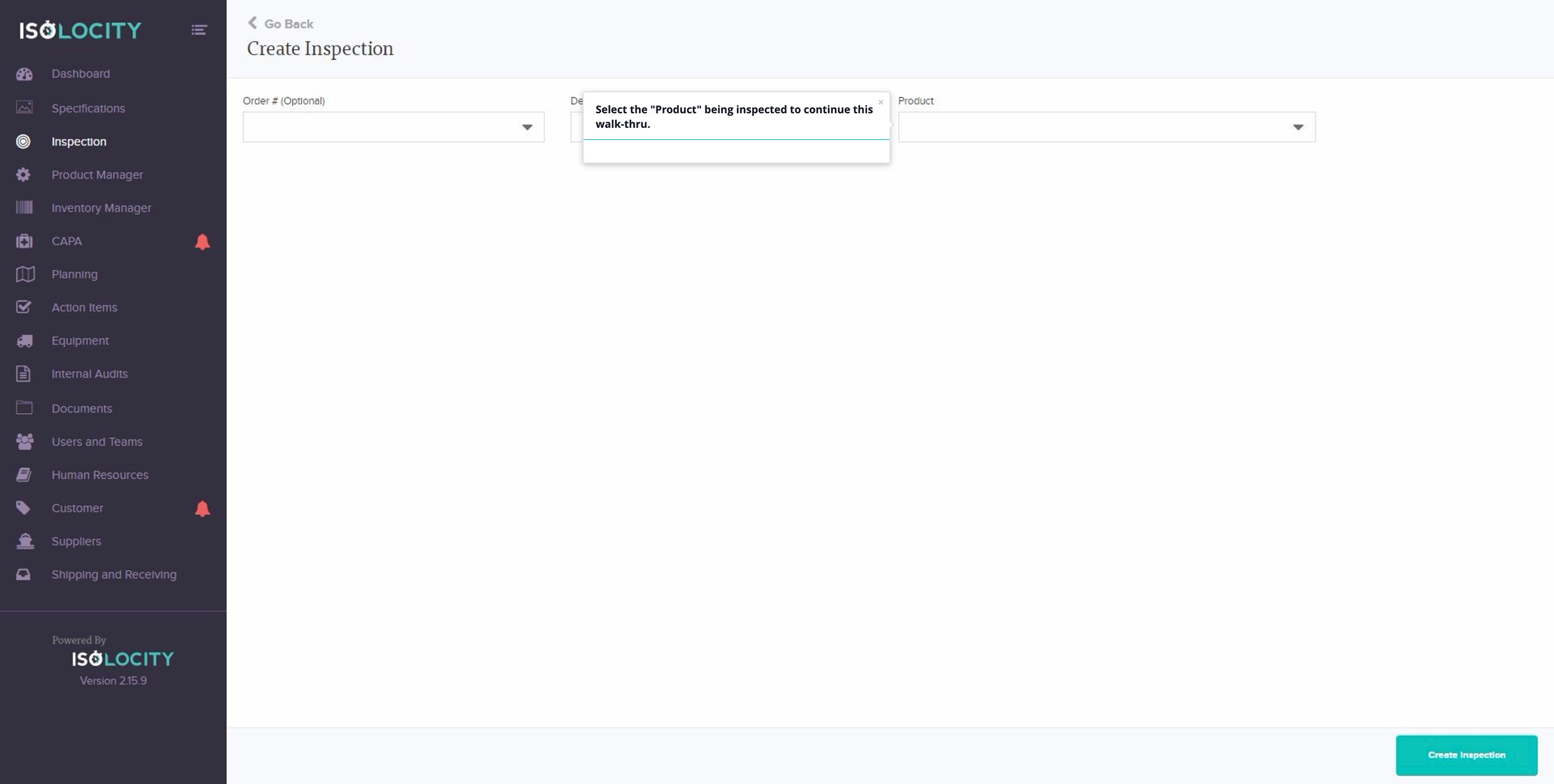

Step #6

Select the “Product” being inspected to continue this walk-thru.

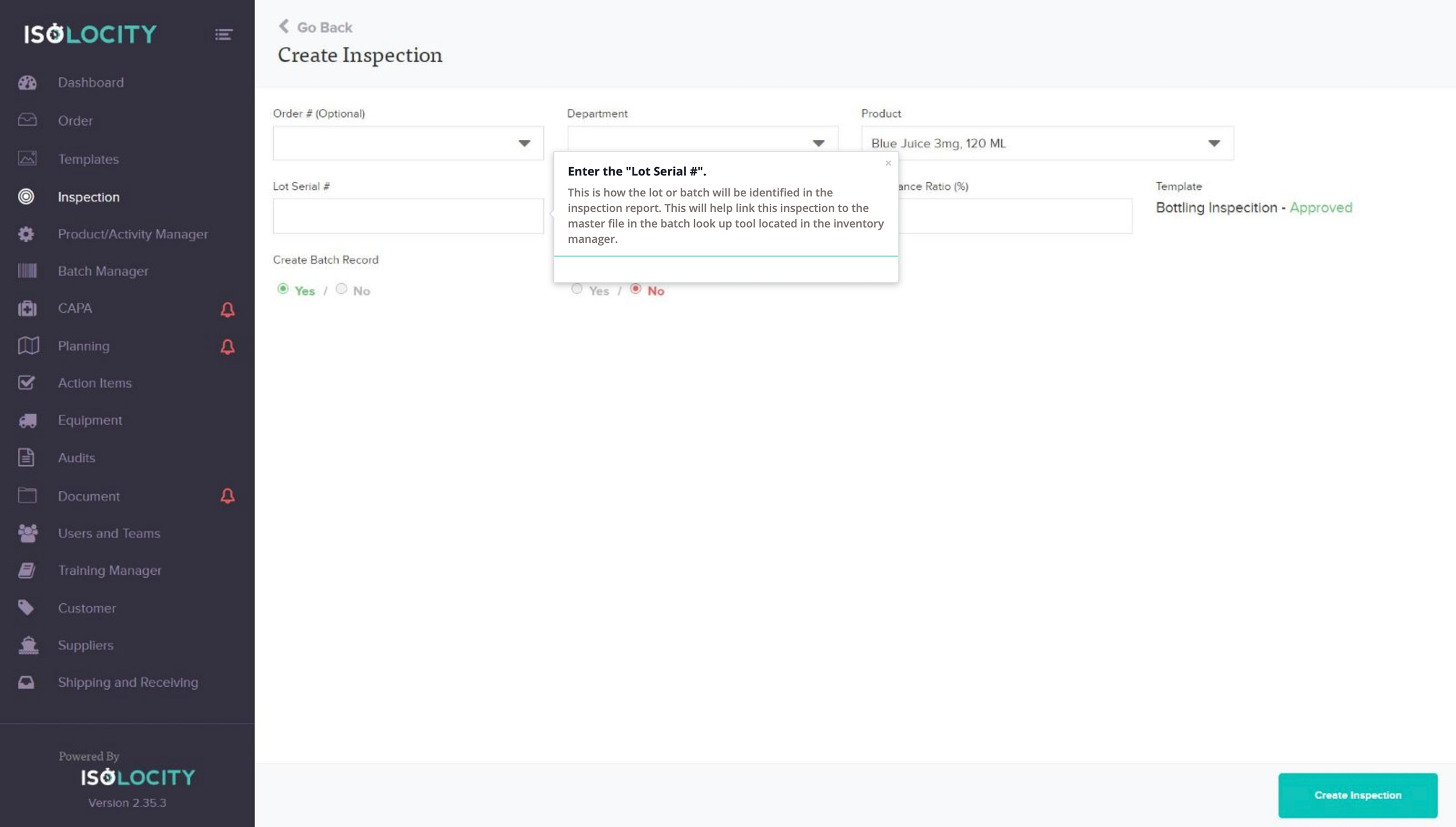

Step #7

Enter the “Lot Serial #”.

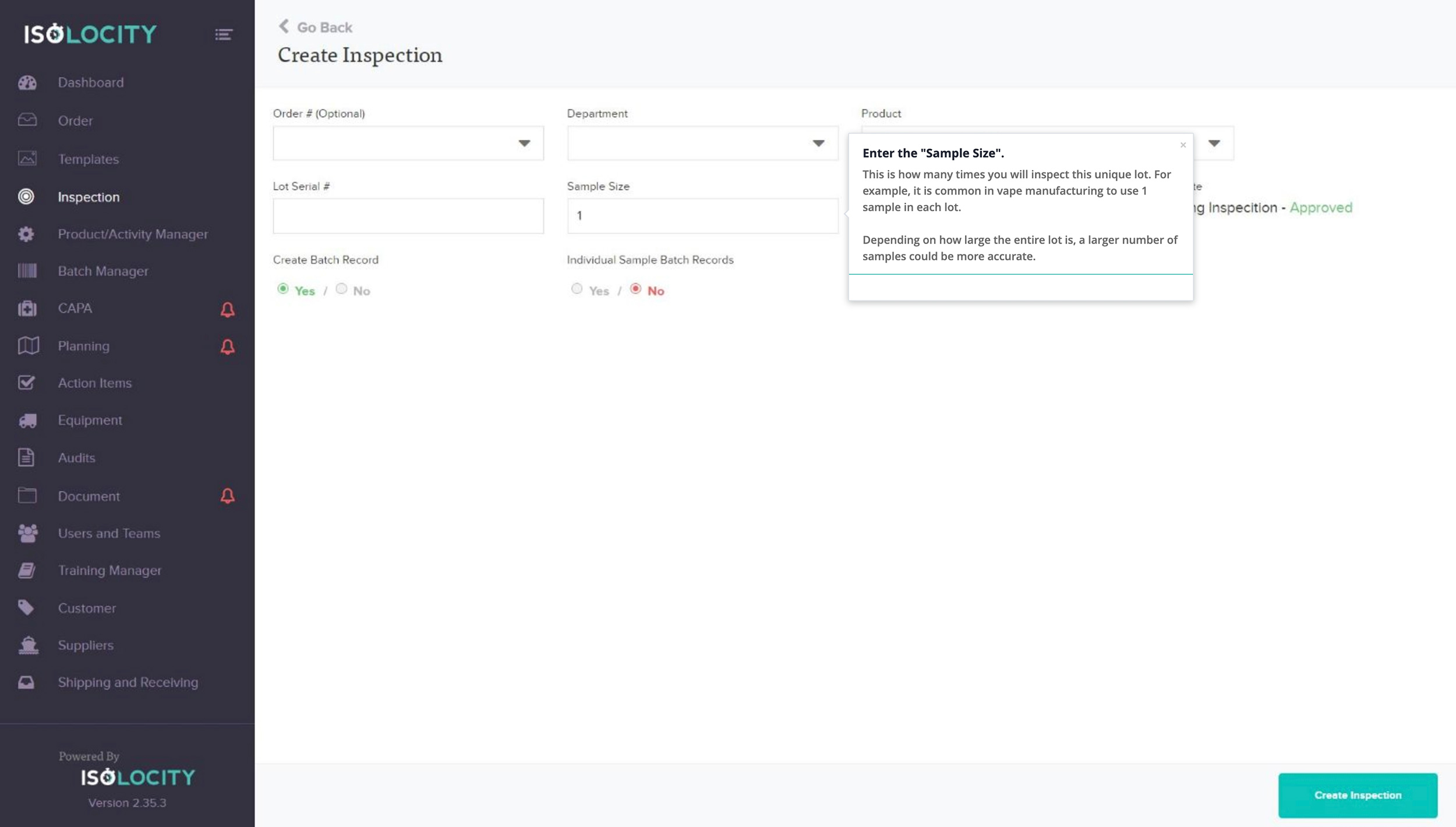

Step #8

Enter the “Sample Size”.

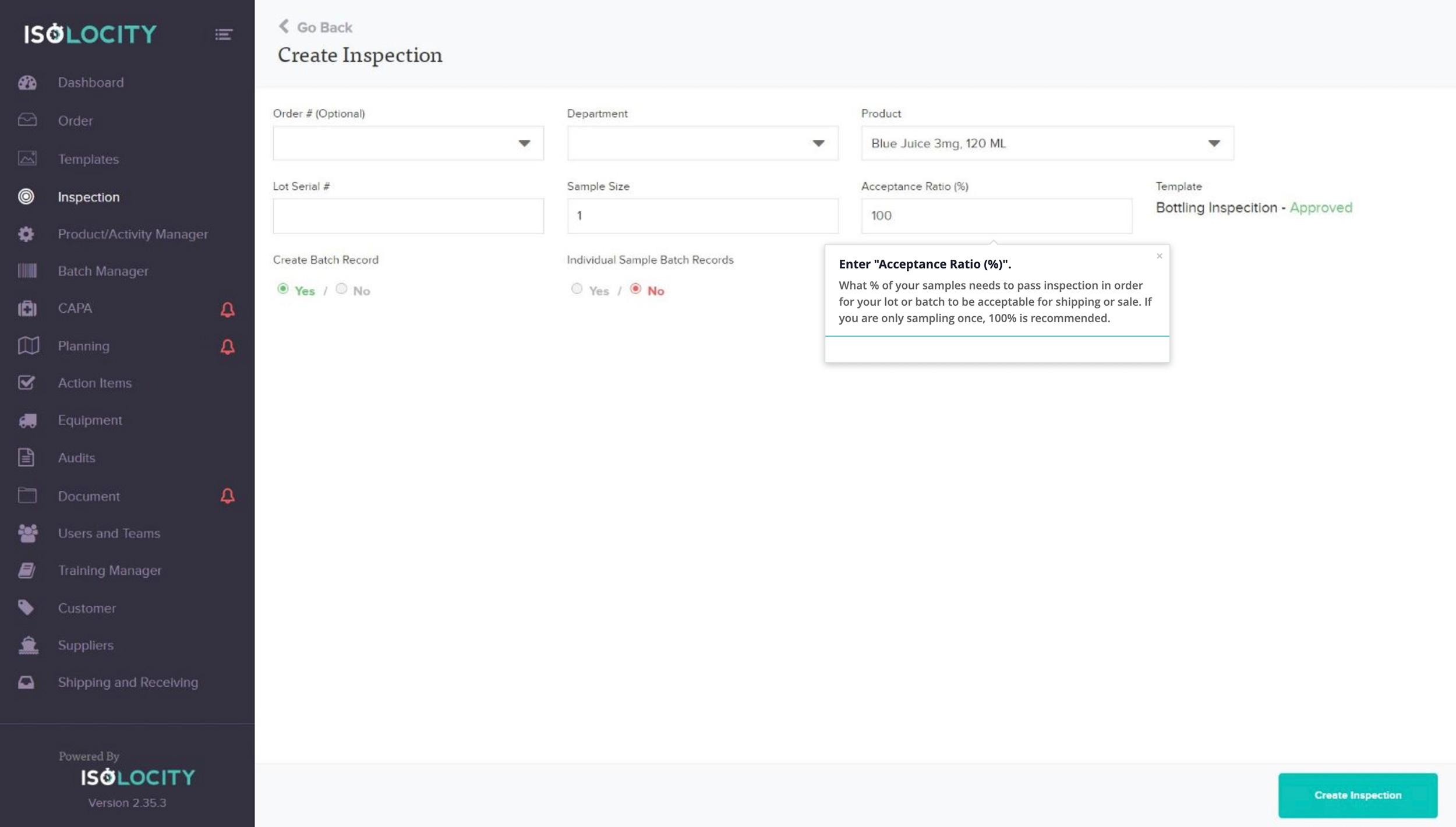

Step #9

Enter “Acceptance Ratio (%)”.

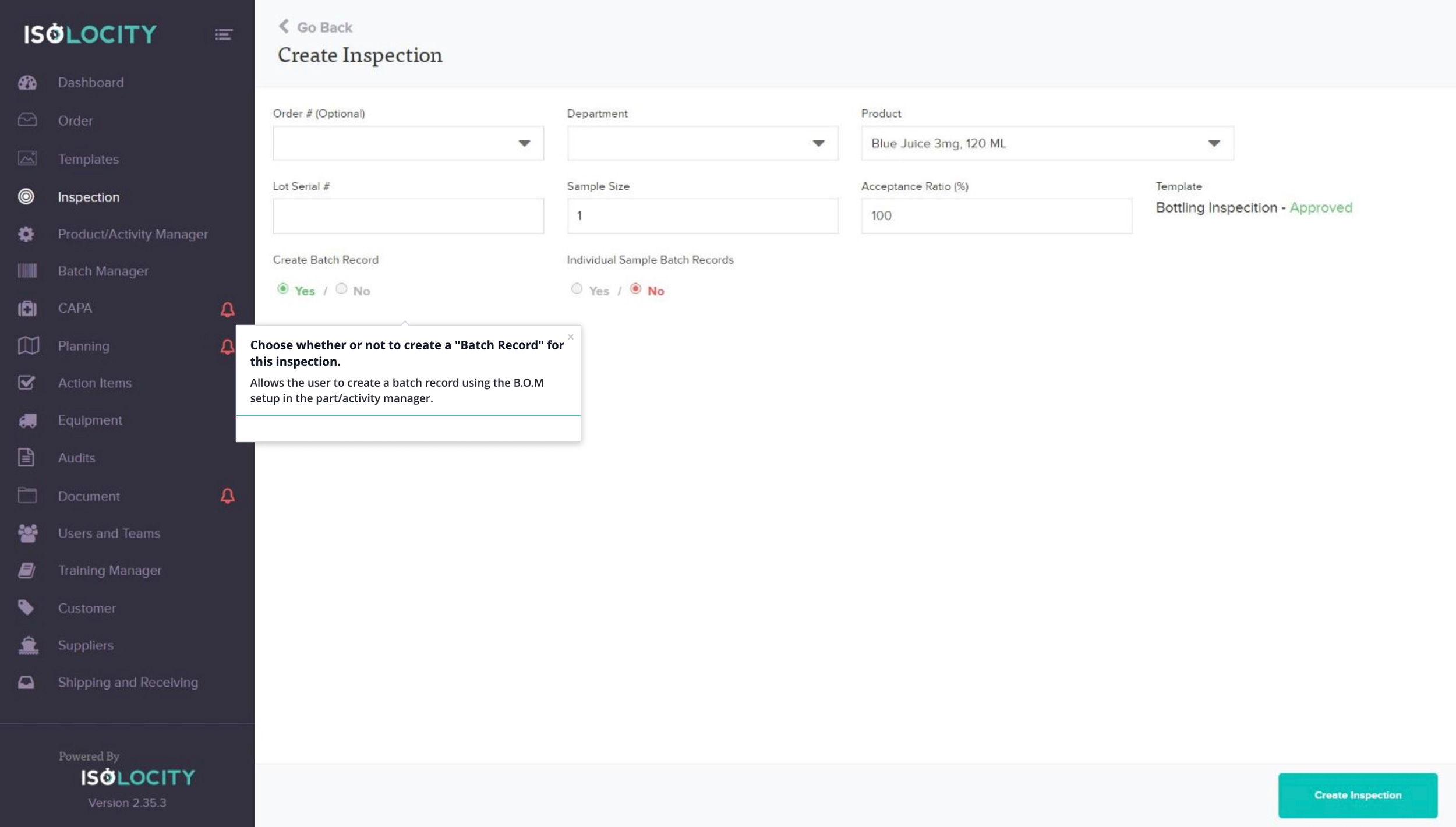

Step #10

Choose whether or not to create a “Batch Record” for this inspection.

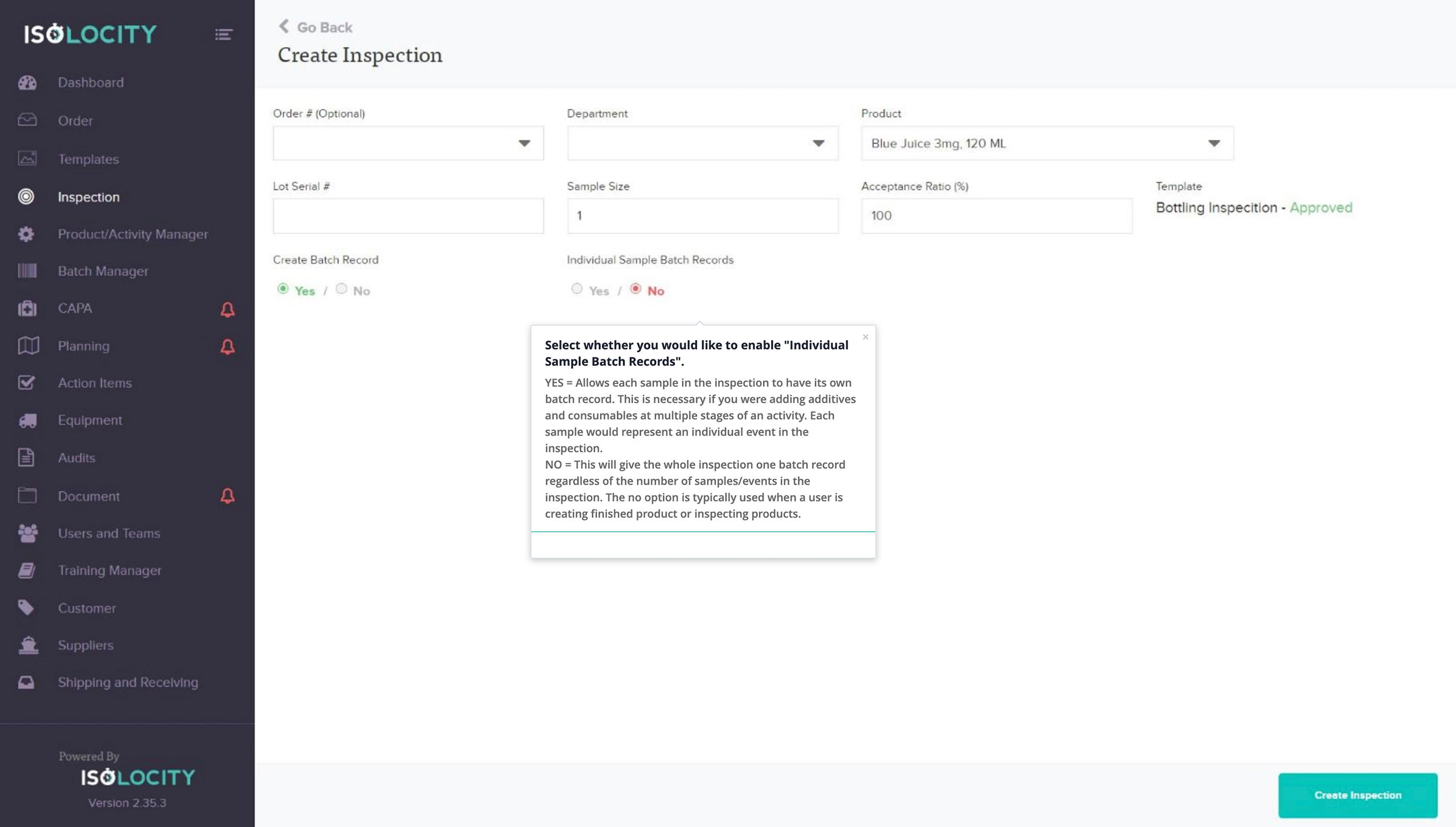

Step #11

Select whether you would like to enable “Individual Sample Batch Records”.

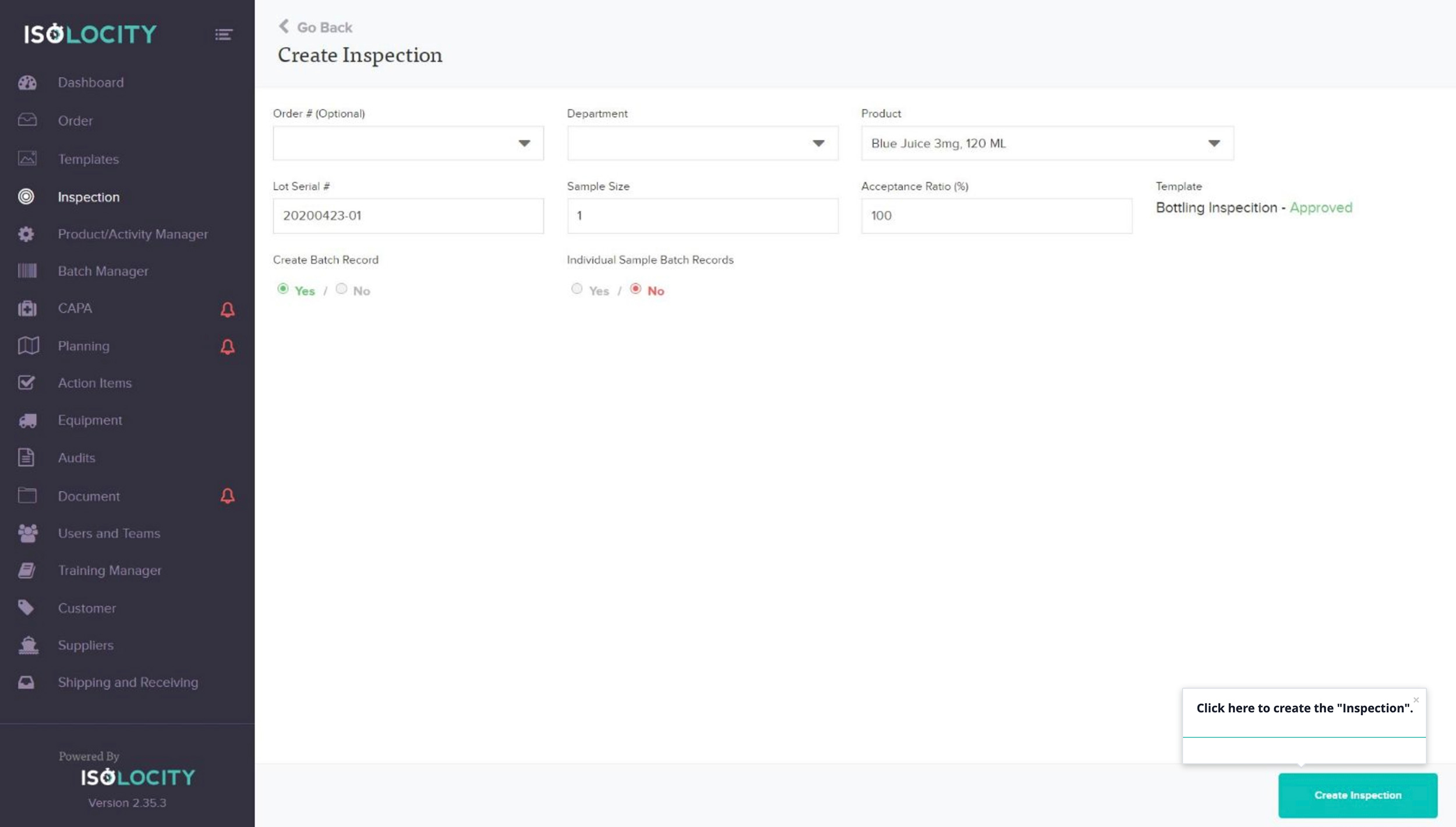

Step #12

Click here to create the “Inspection”.

Step #13

Errors on screen! Fix errors then click “Create Inspection”

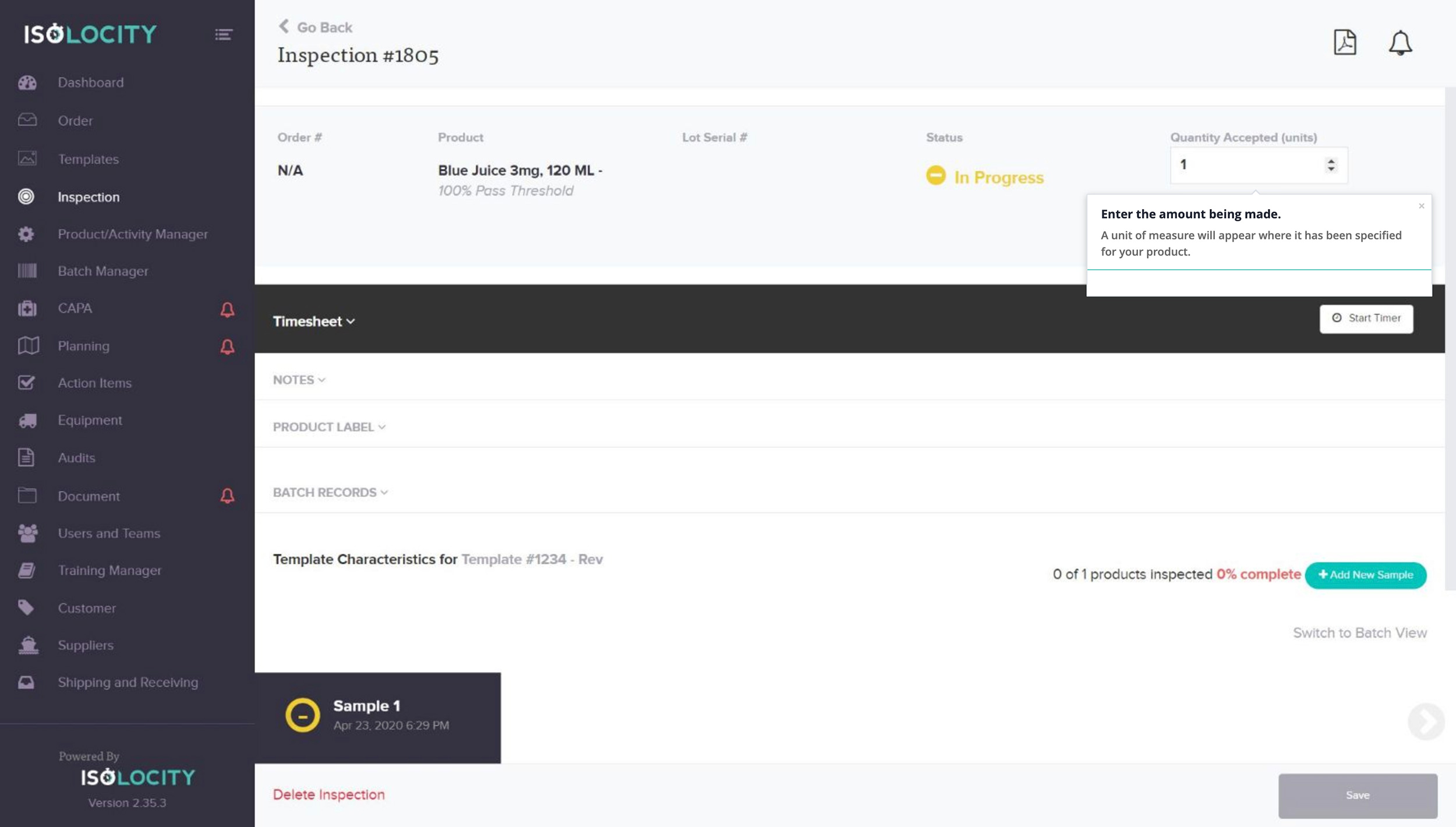

Step #14

Enter the amount being made.

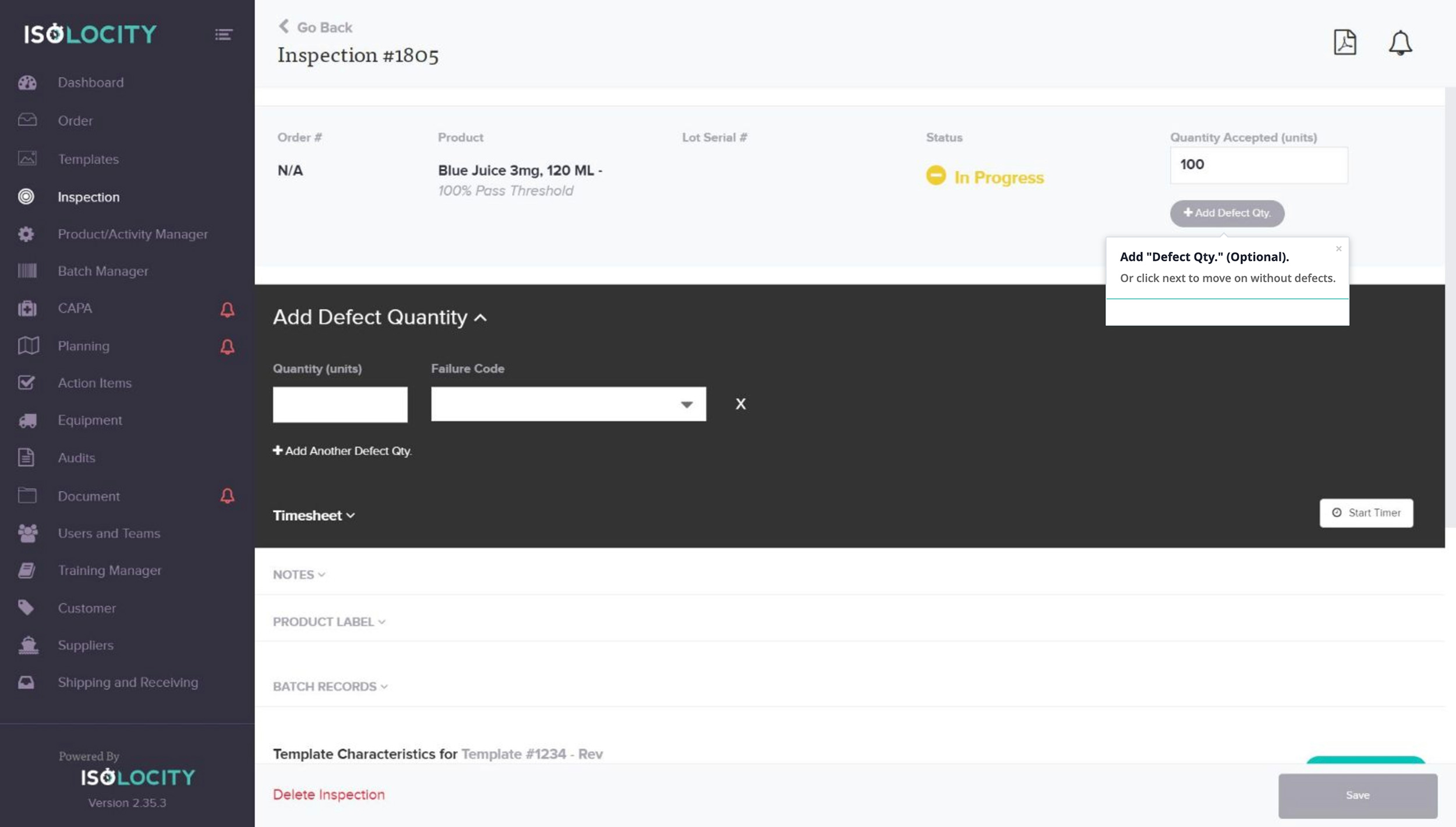

Step #15

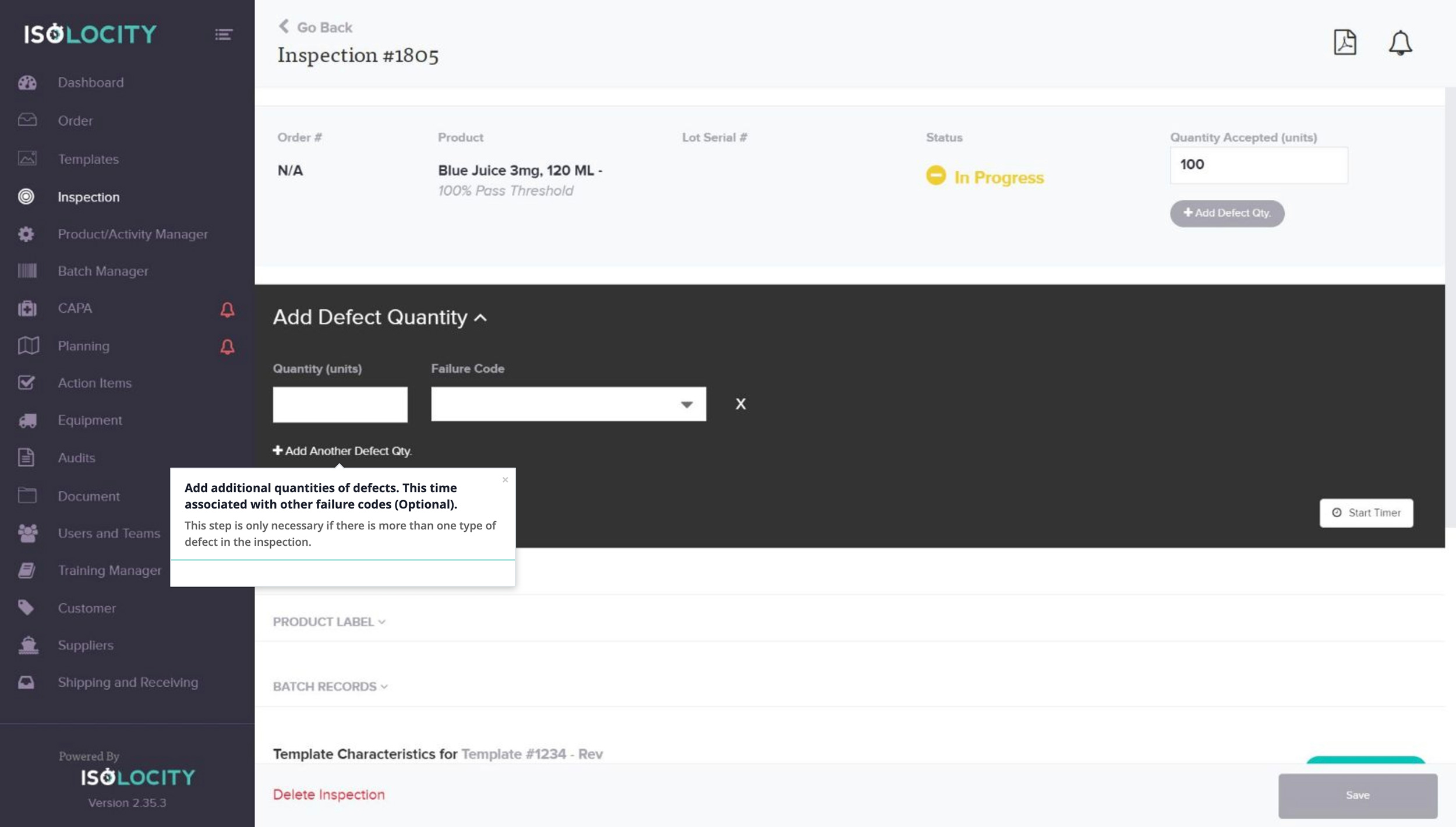

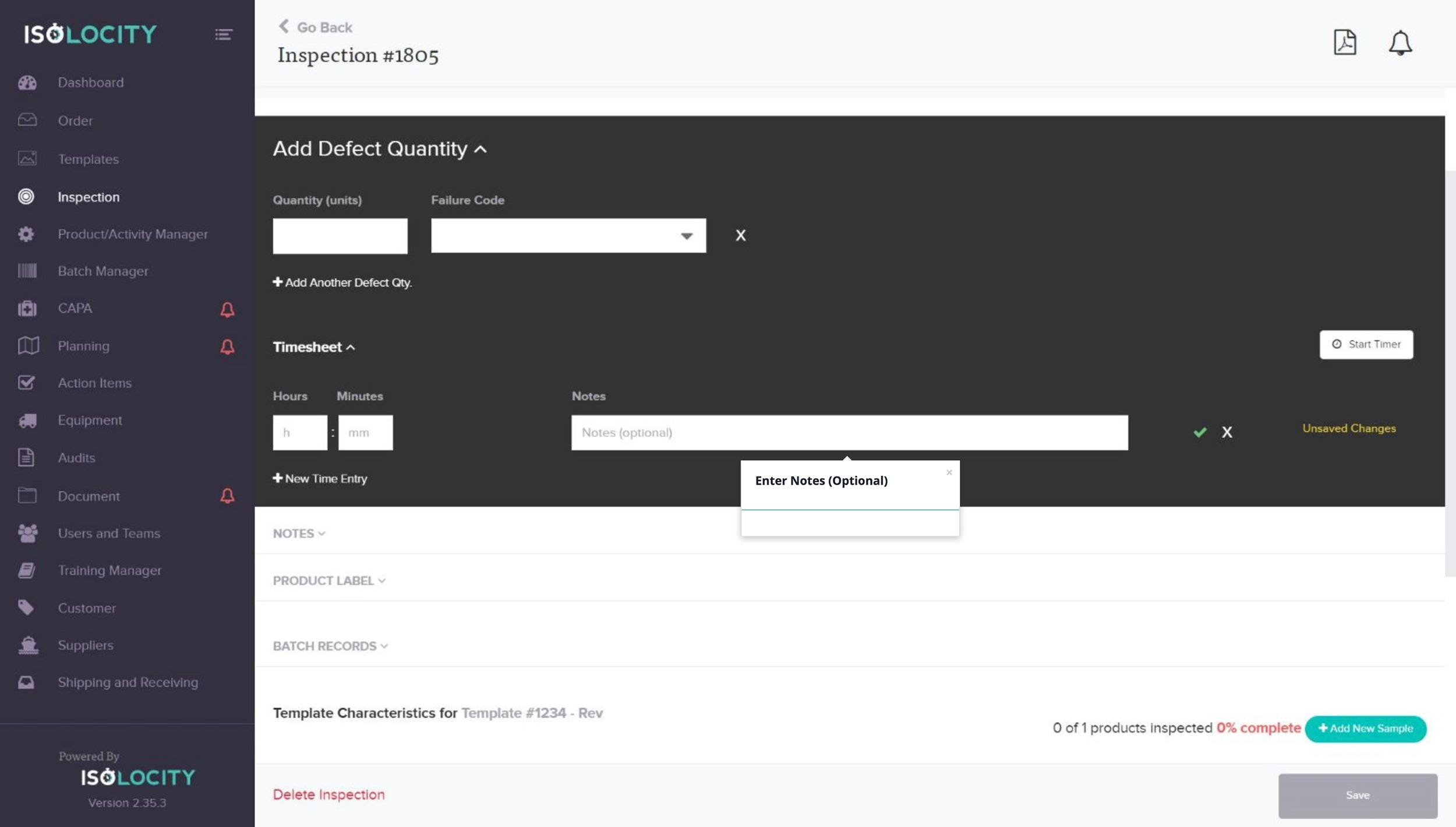

Add “Defect Qty.” (Optional).

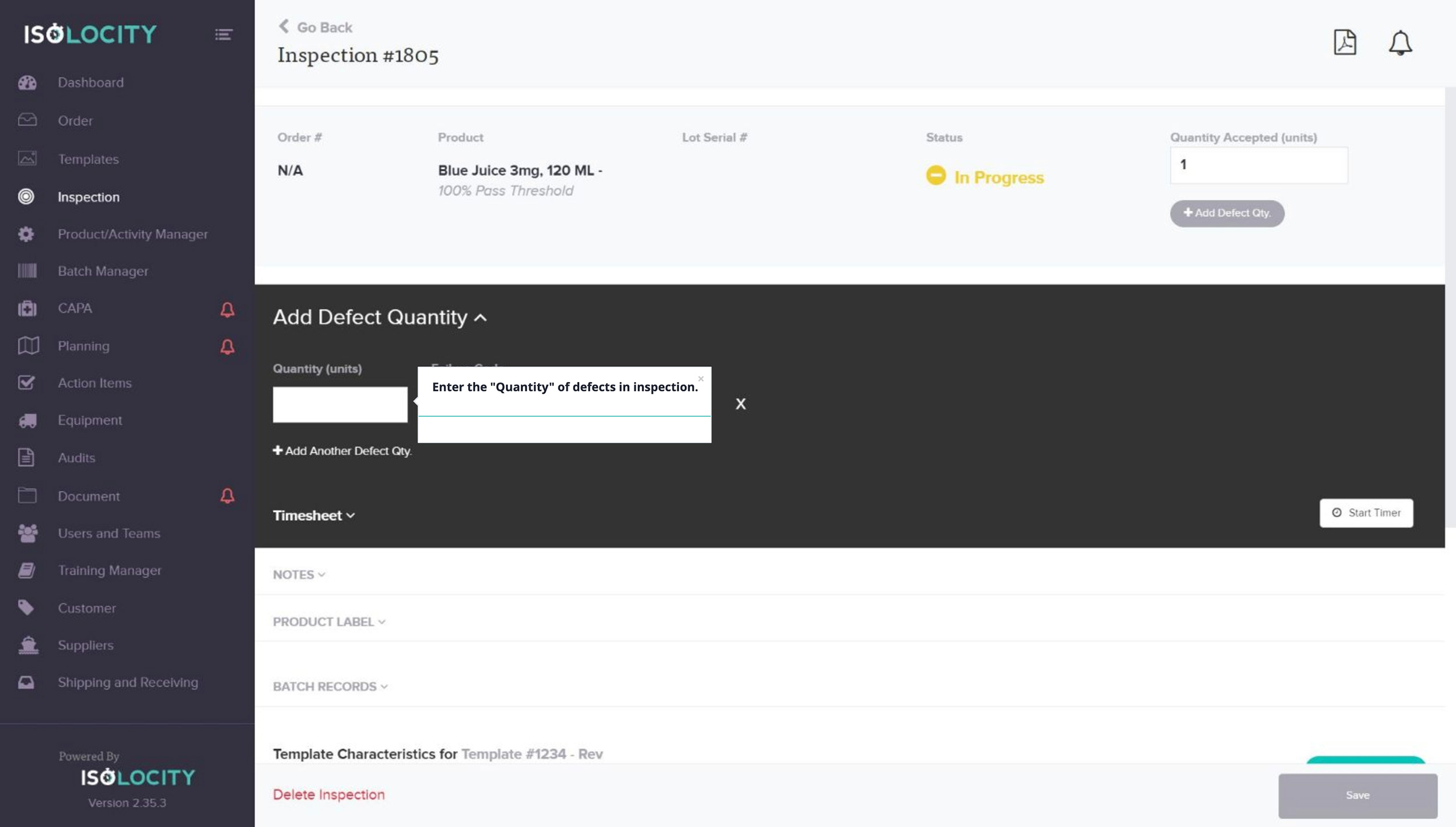

Step #16

Enter the “Quantity” of defects in inspection.

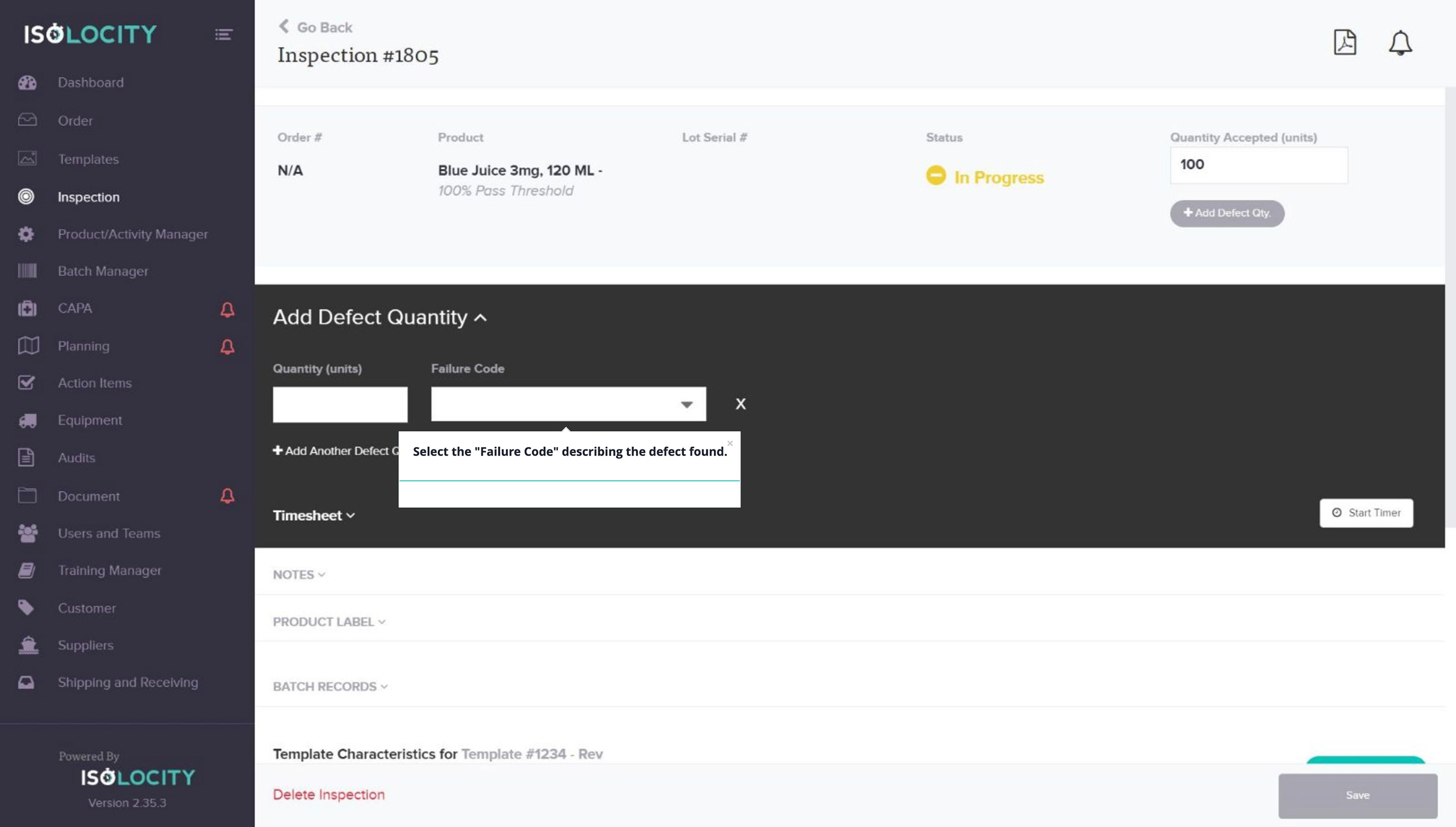

Step #17

Select the “Failure Code” describing the defect found.

Step #18

Add additional quantities of defects. This time associated with other failure codes (Optional).

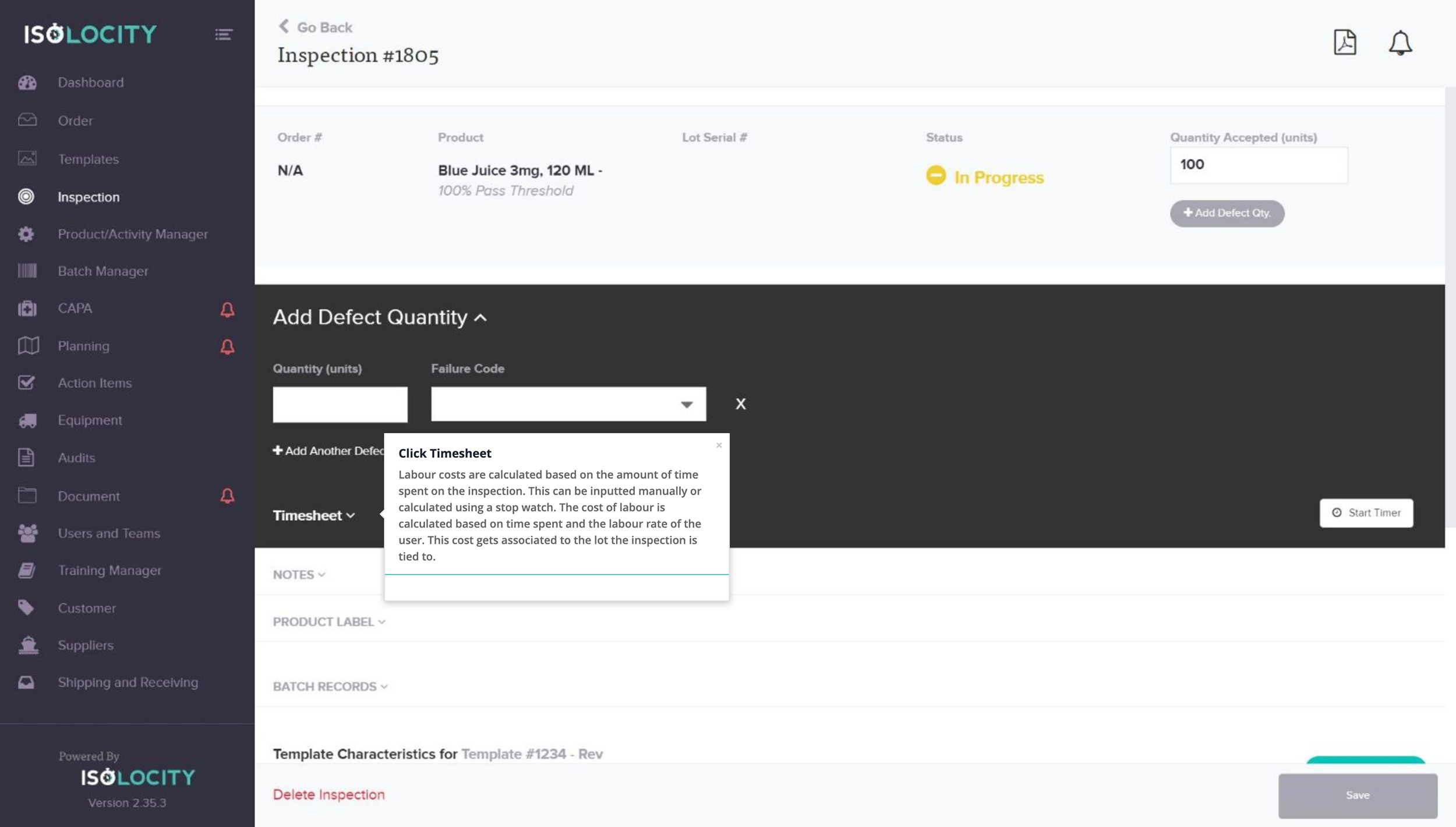

Step #19

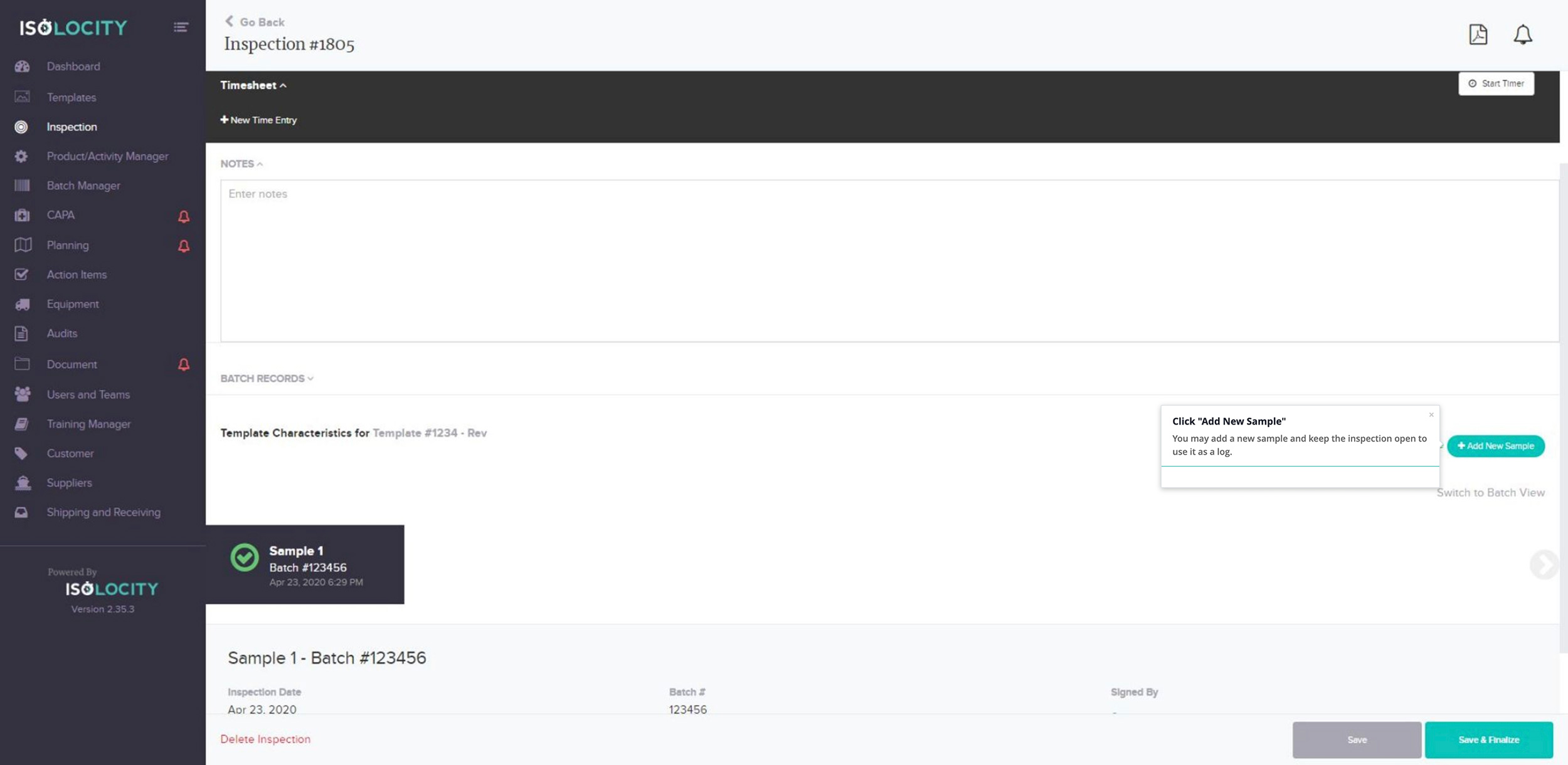

Click Timesheet

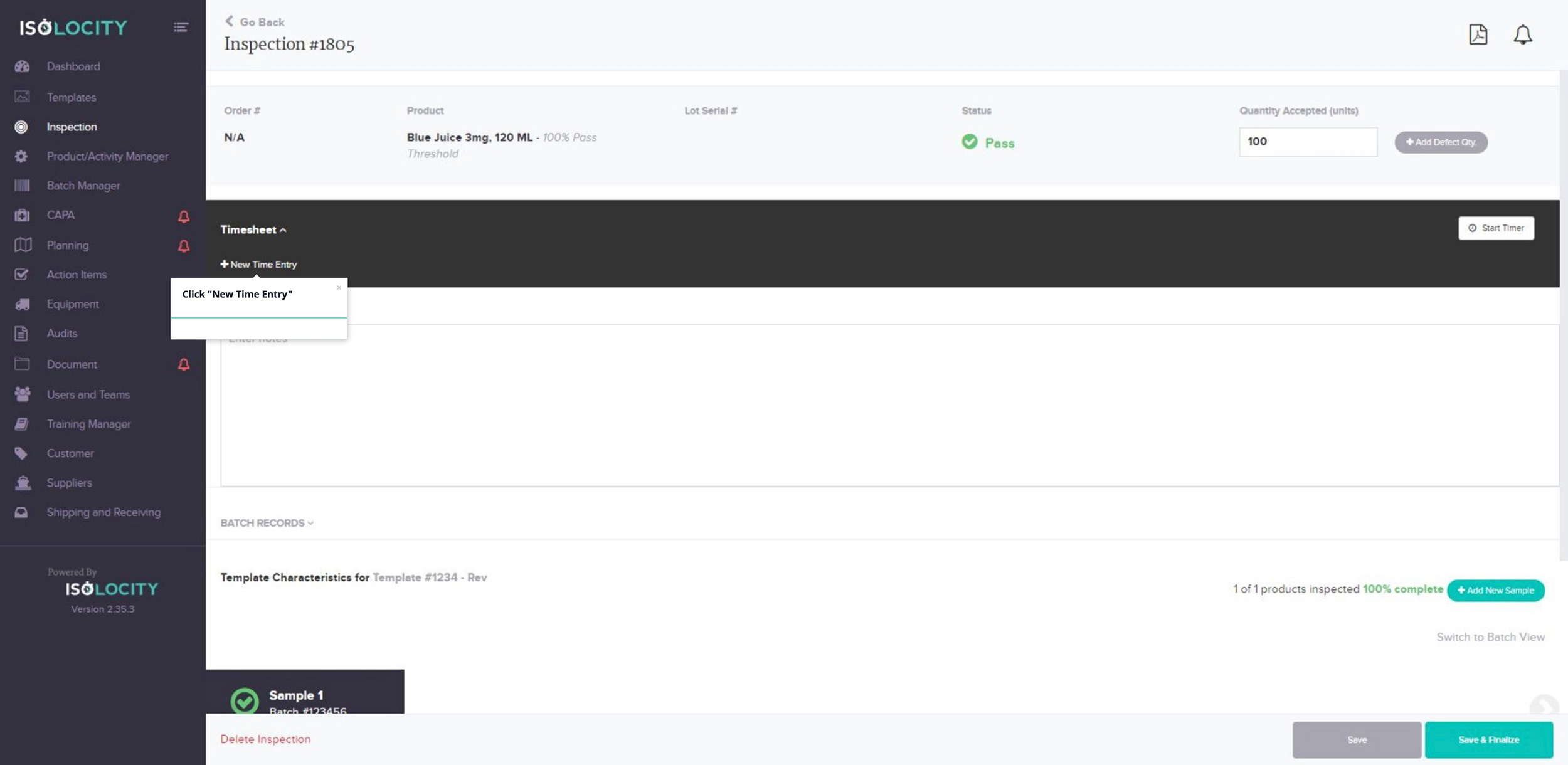

Step #20

Click “New Time Entry”

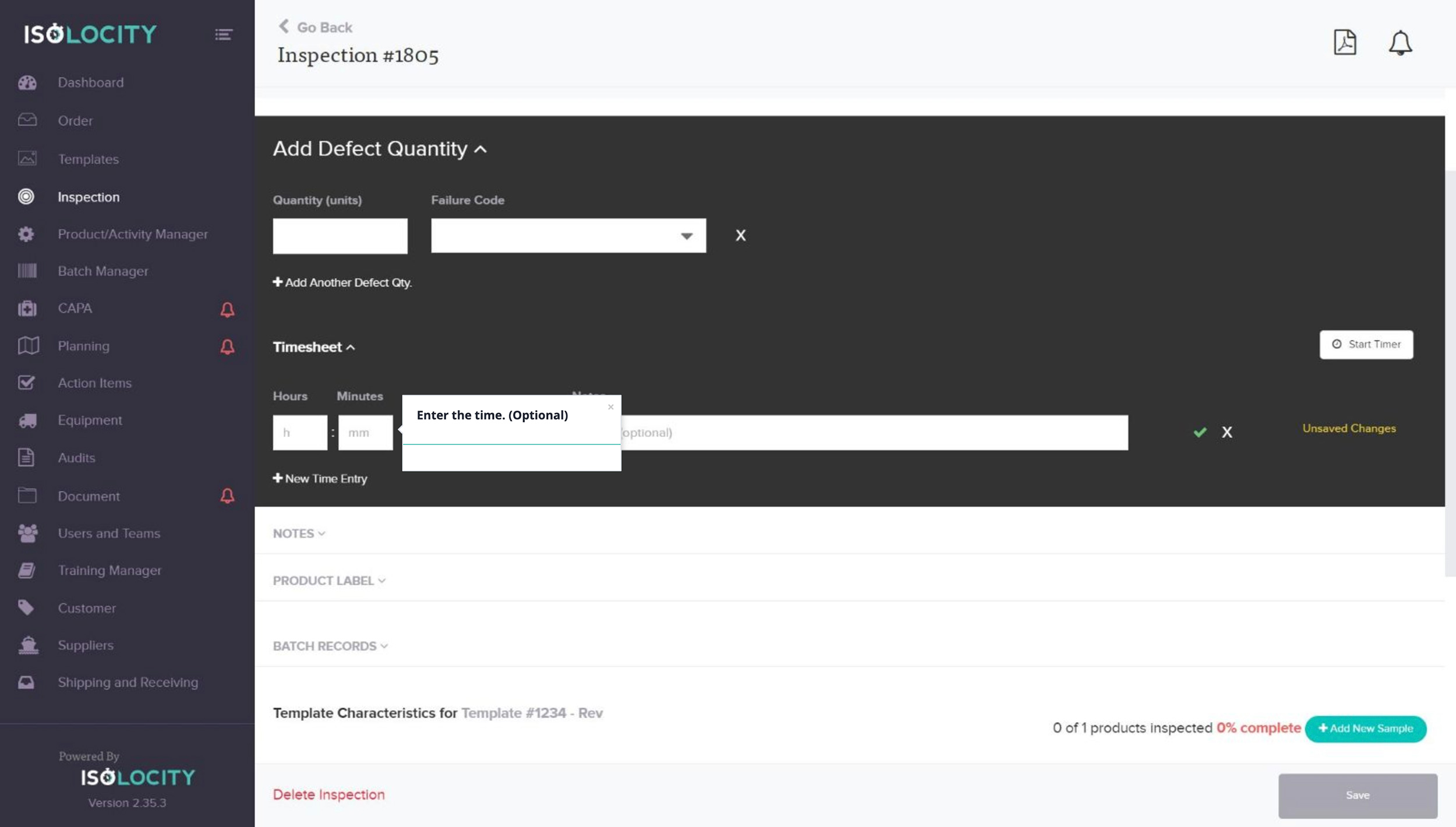

Step #21

Enter the time. (Optional)

Step #22

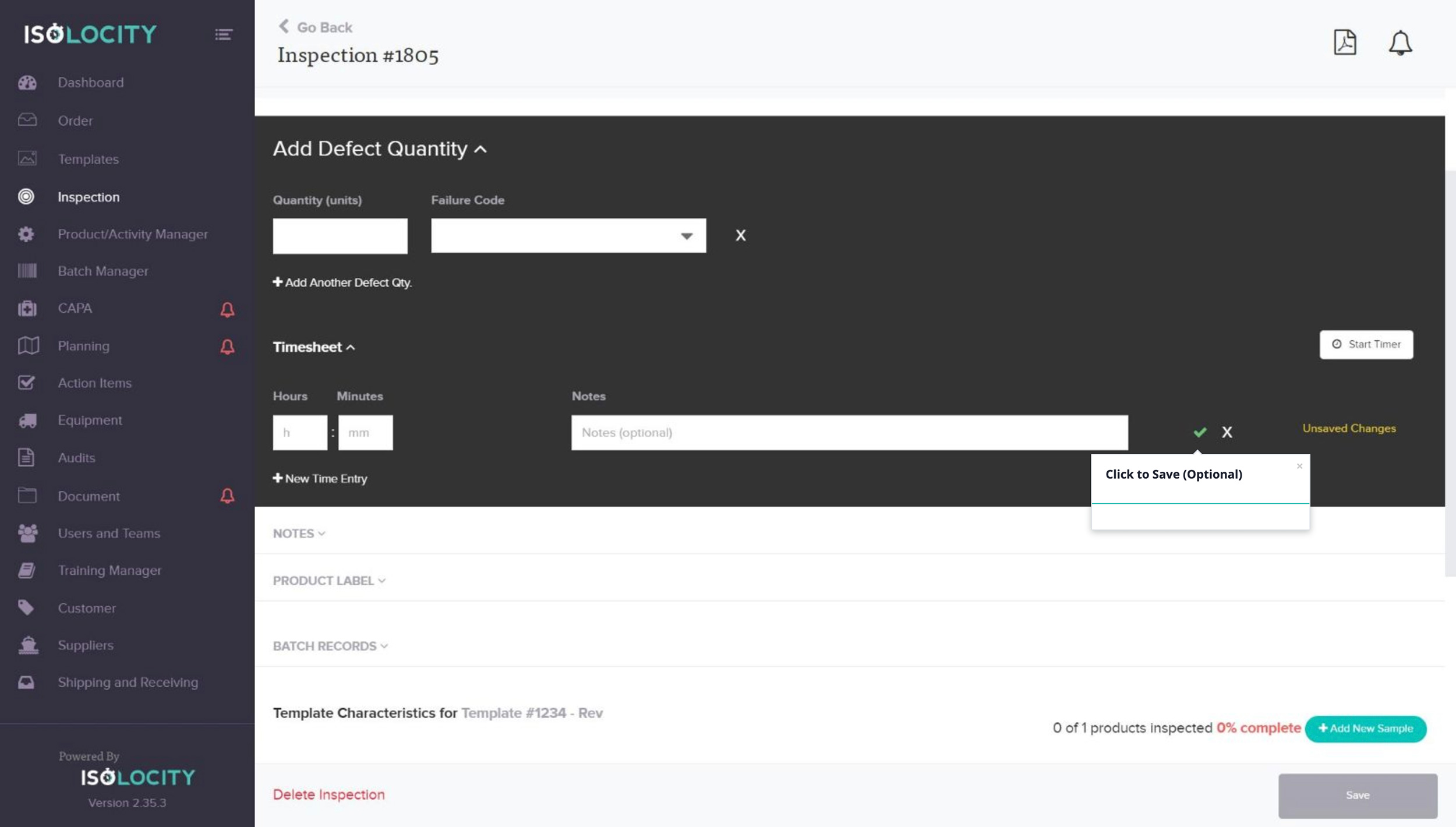

Enter Notes (Optional)

Step #23

Click to Save (Optional)

Step #24

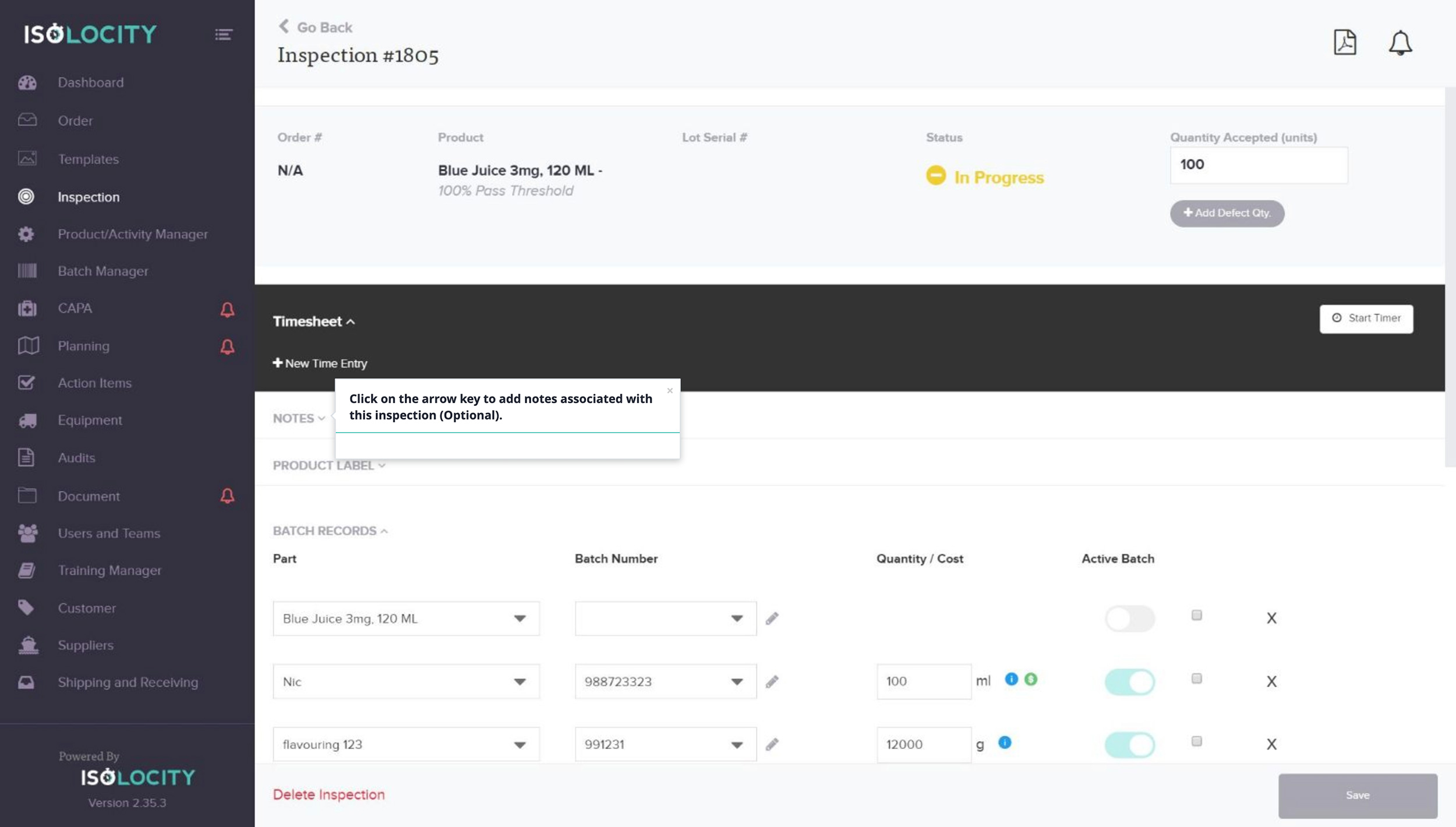

Click on the arrow key to add notes associated with this inspection (Optional).

Step #25

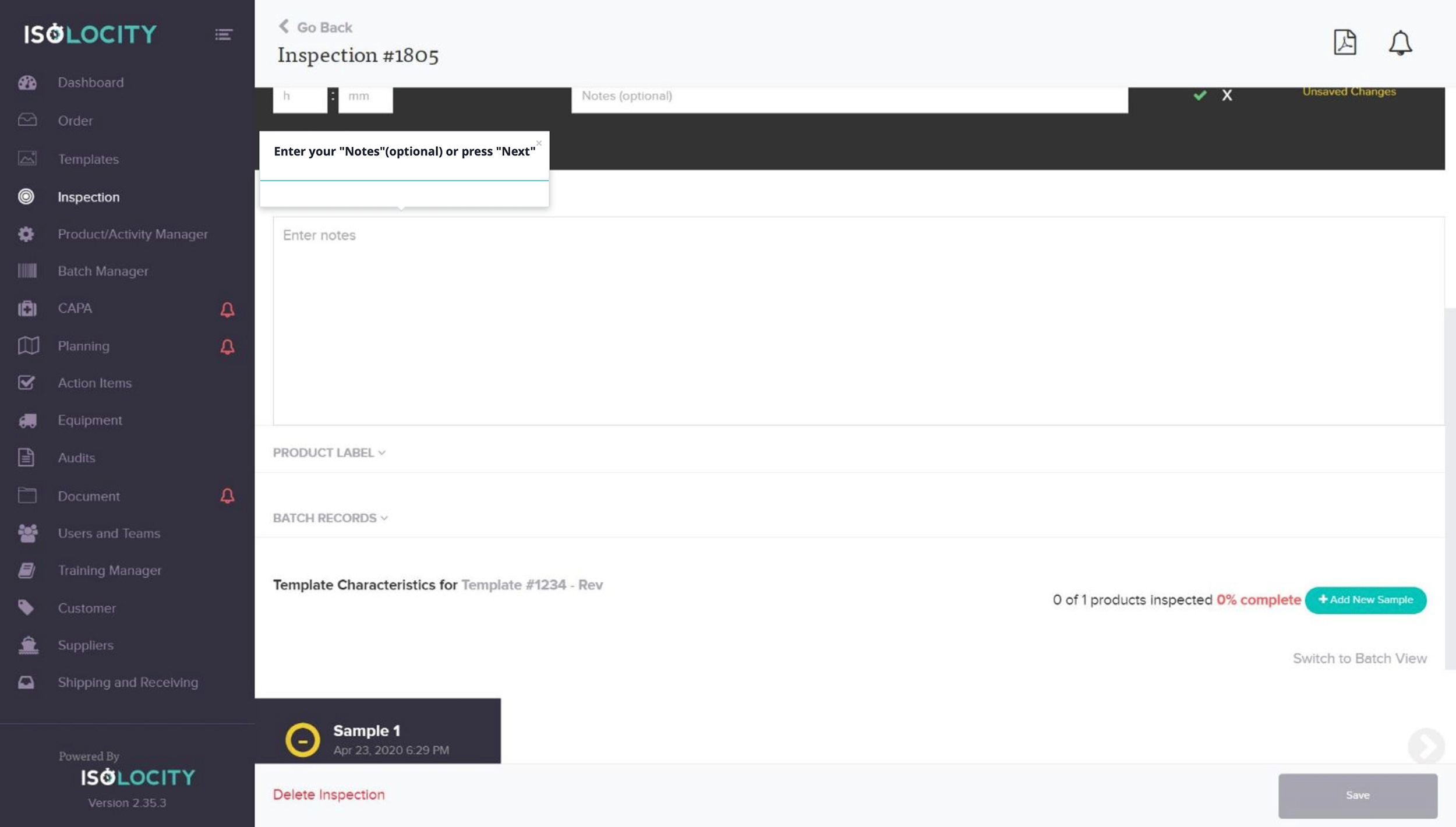

Enter your “Notes”(optional) or press “Next”

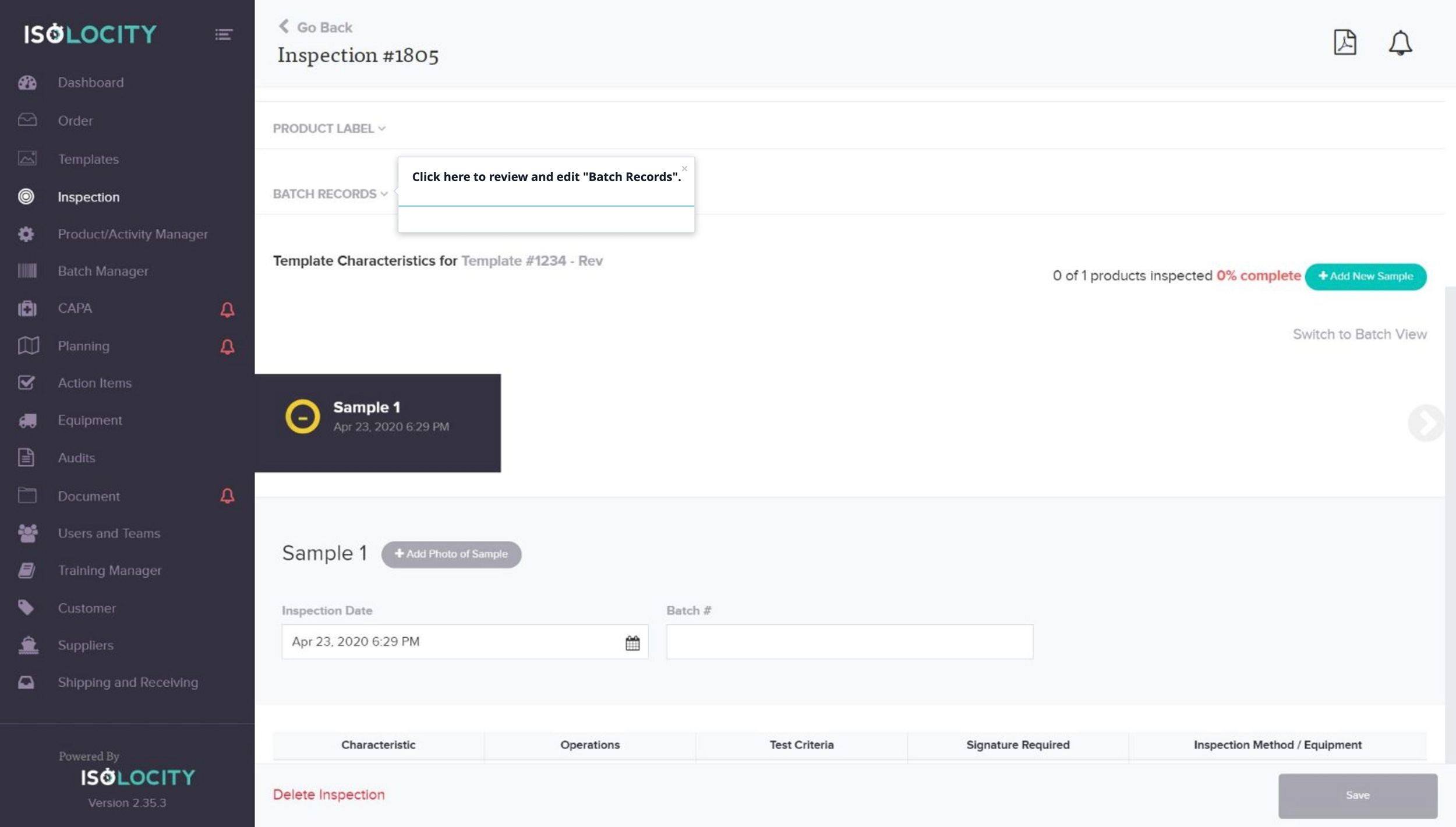

Step #26

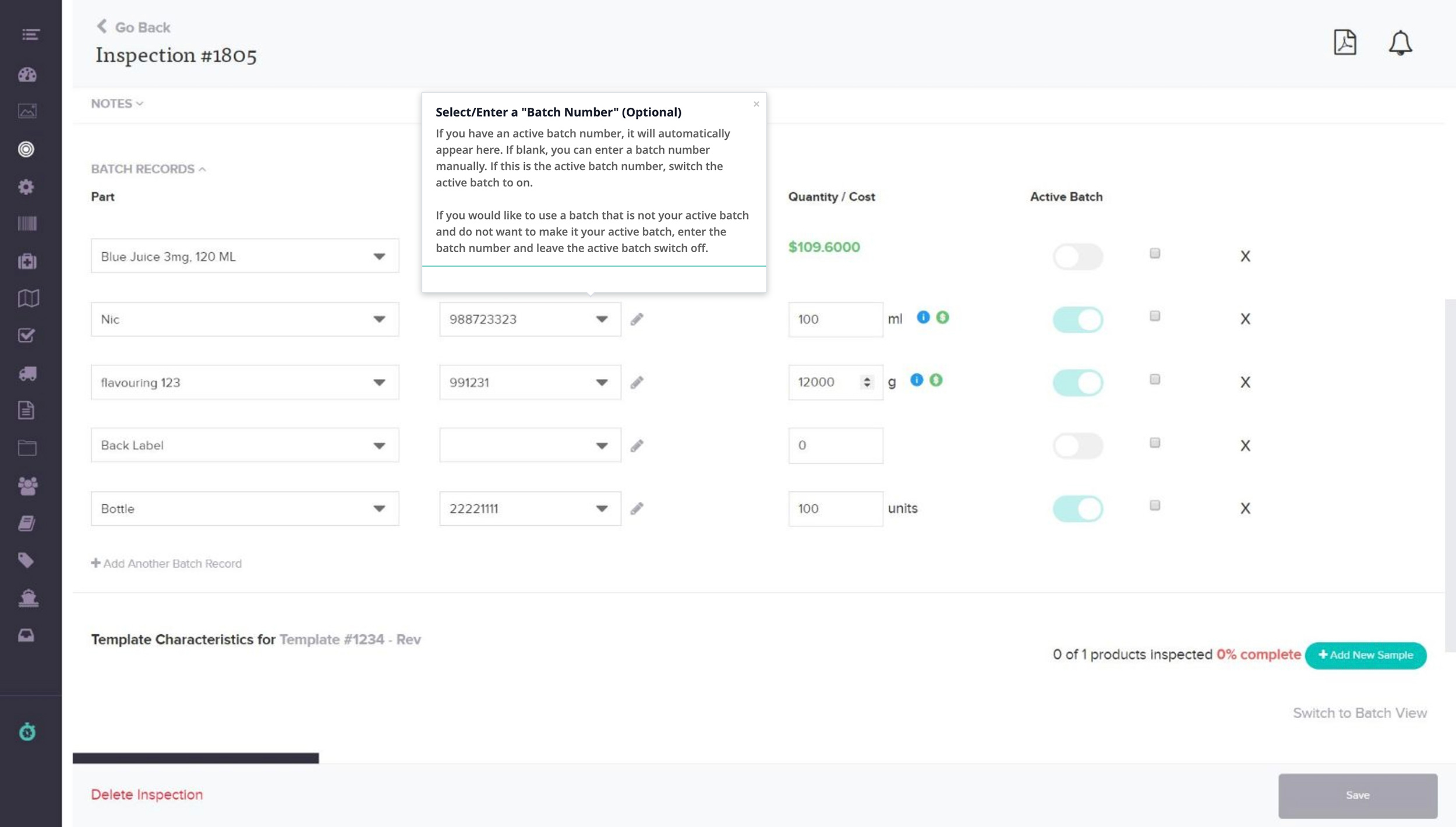

Click here to review and edit “Batch Records”.

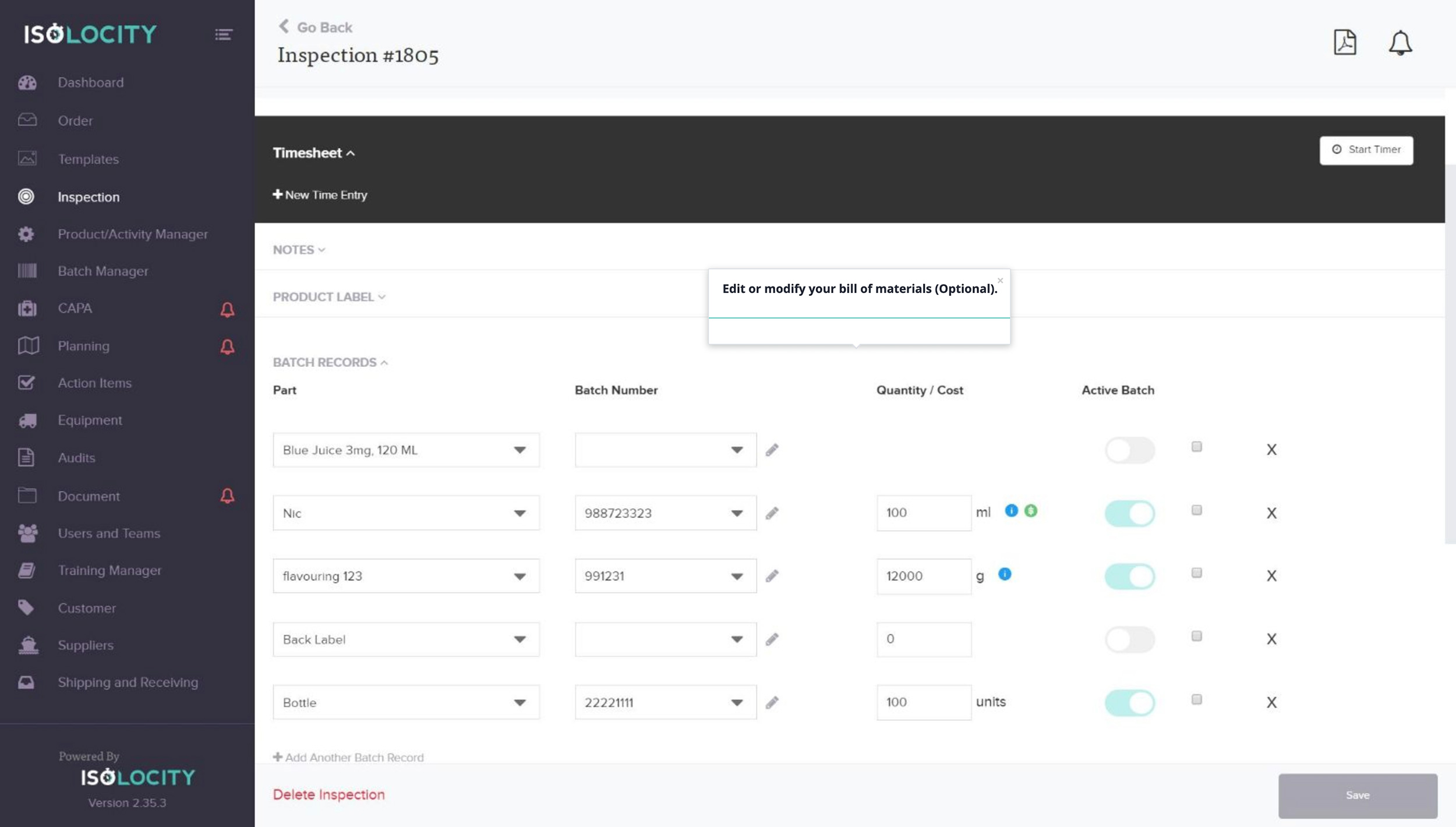

Step #27

Edit or modify your bill of materials (Optional).

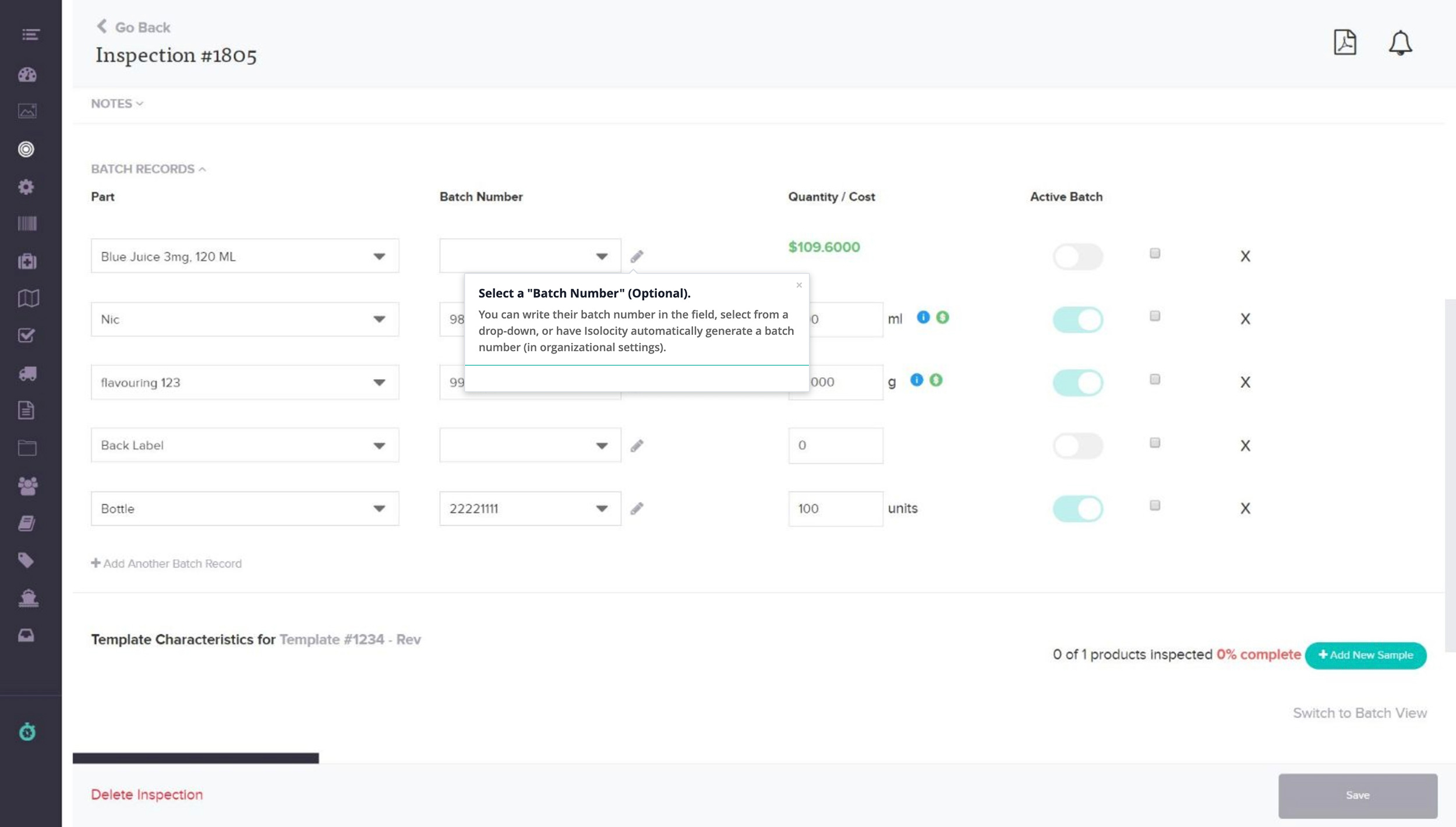

Step #28

Select a “Batch Number” (Optional).

Step #29

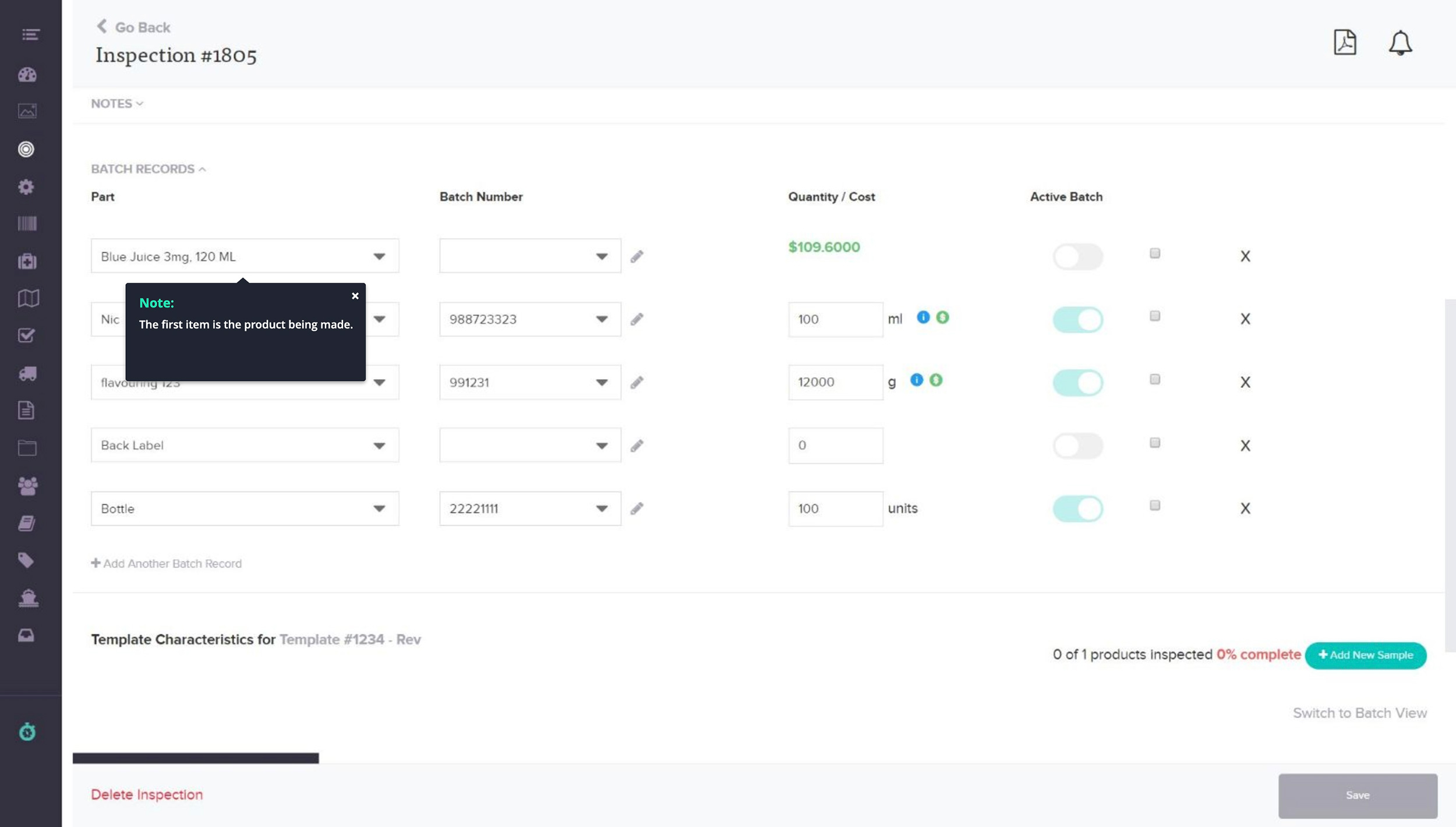

Note

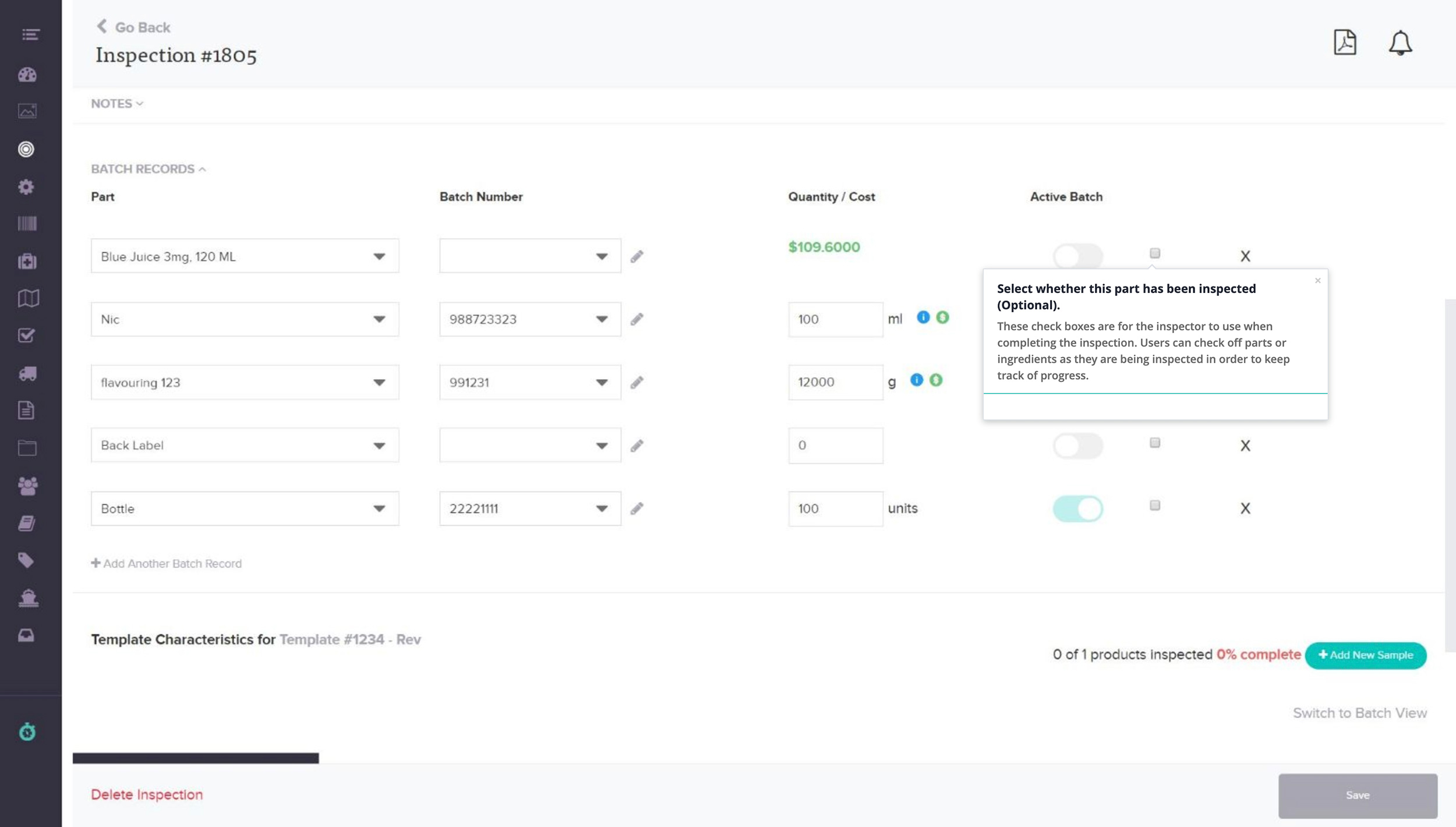

Step #30

Select whether this part has been inspected (Optional).

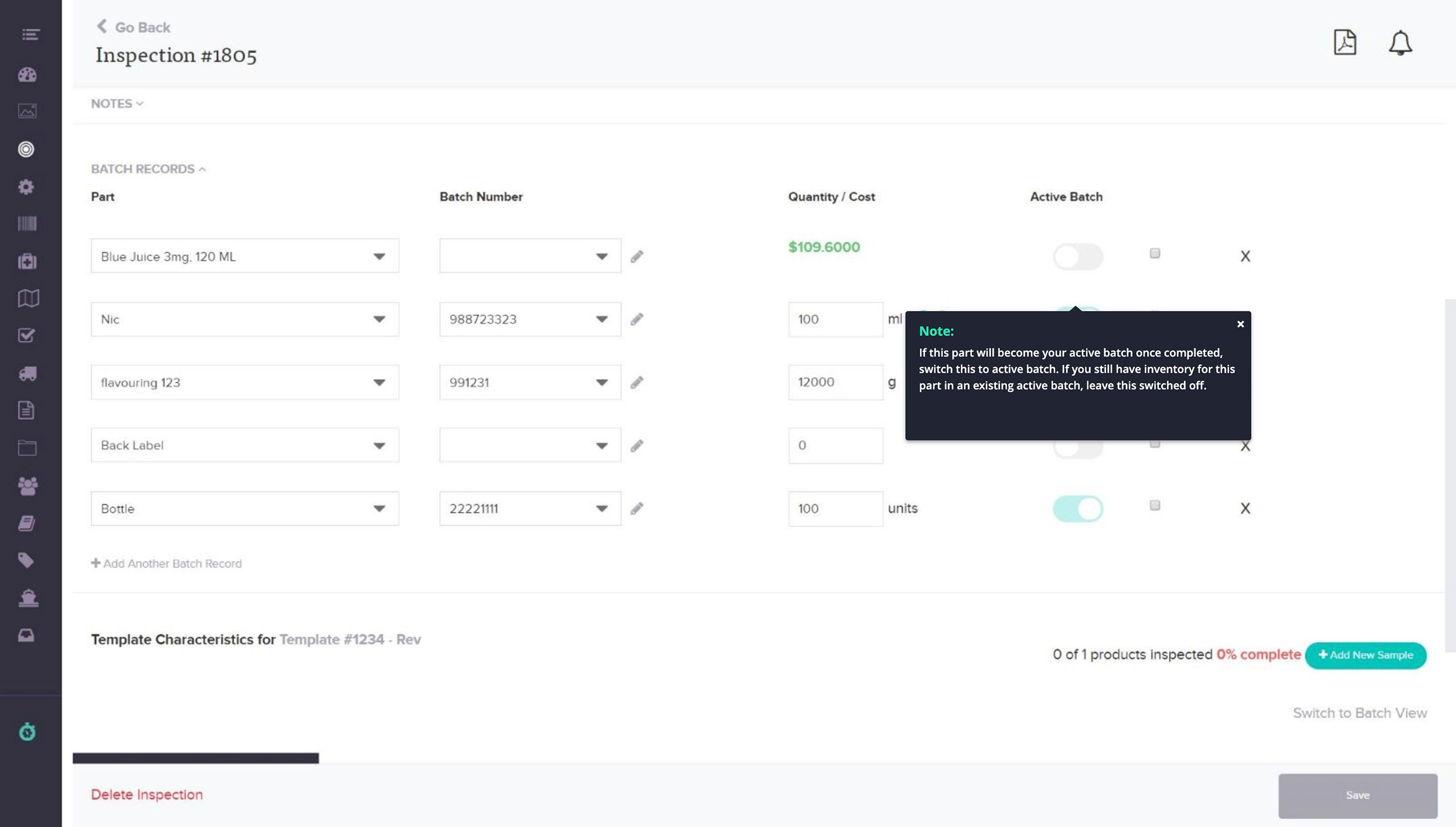

Step #31

Note

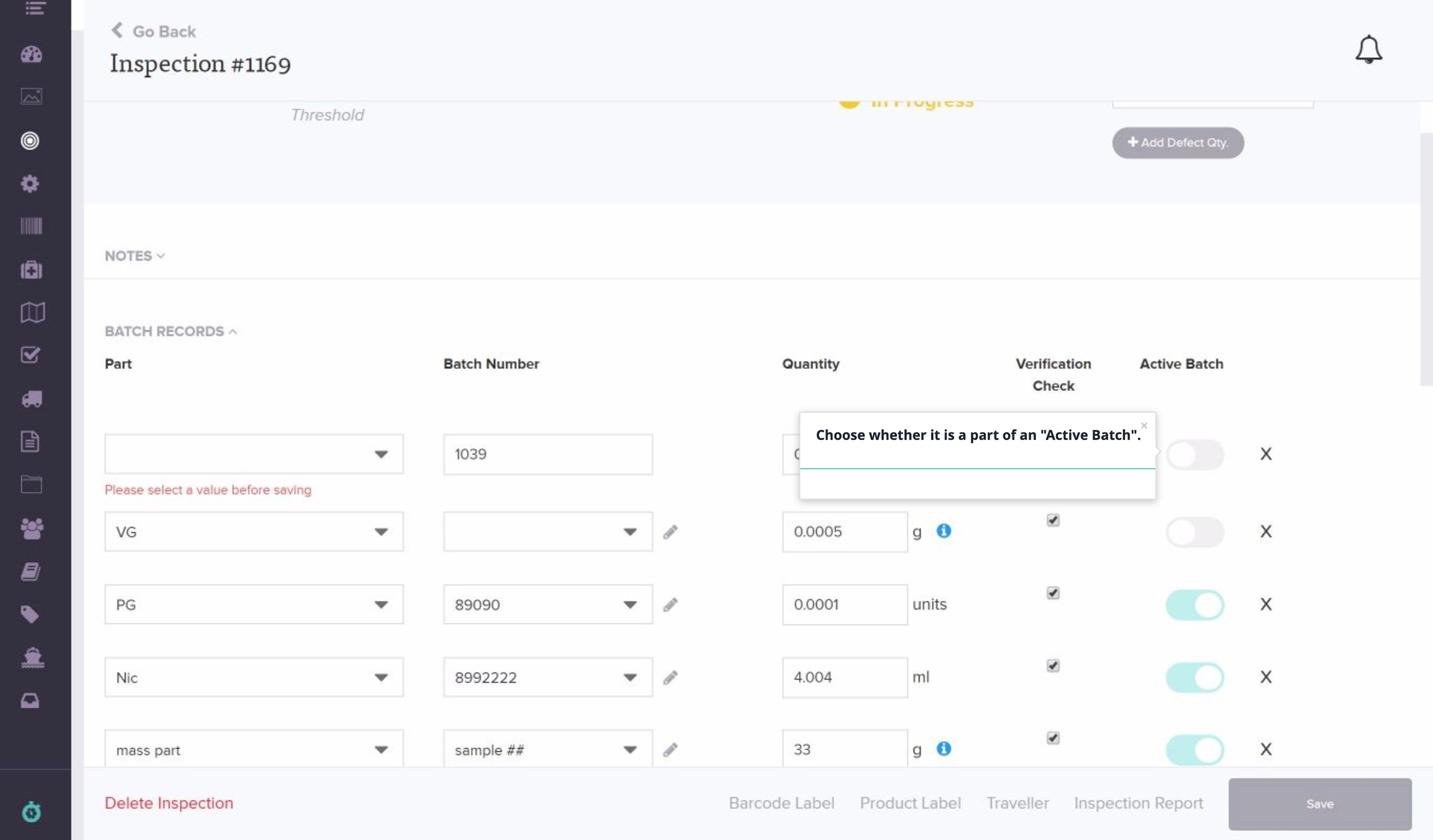

Step #32

Choose whether it is a part of an “Active Batch”.

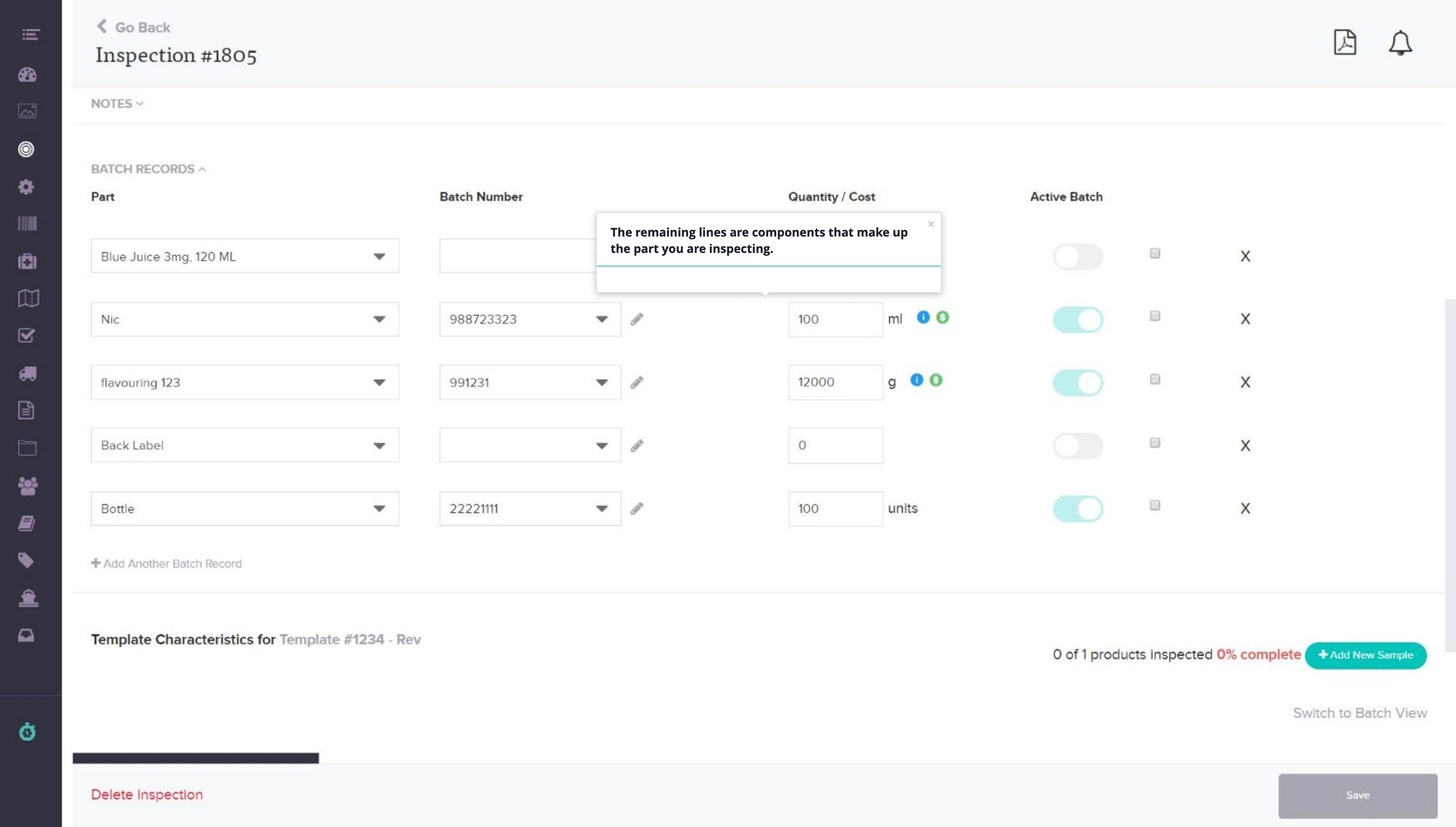

Step #33

The remaining lines are components that make up the part you are inspecting.

Step #34

Select/Enter a “Batch Number” (Optional)

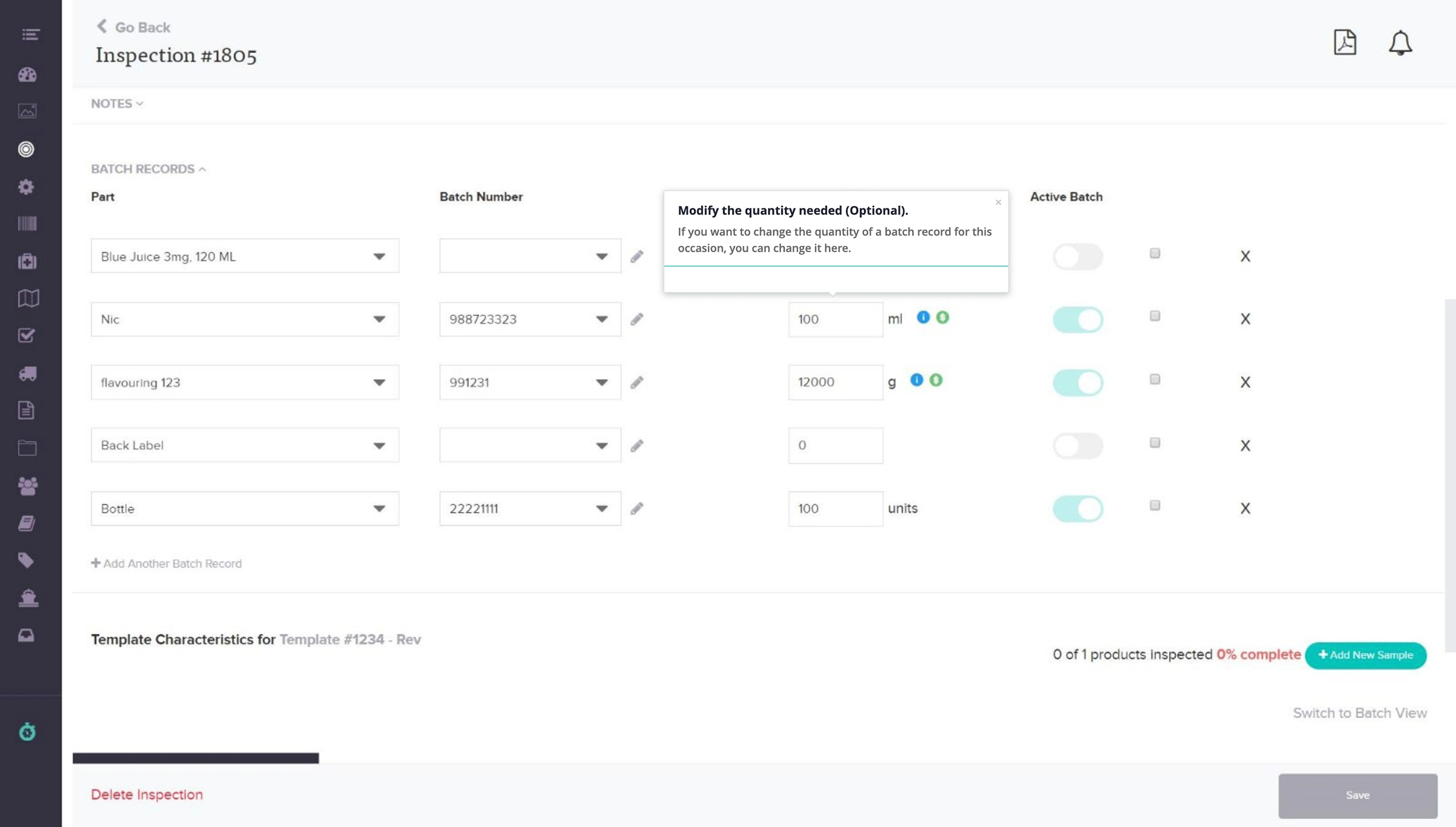

Step #35

Modify the quantity needed (Optional).

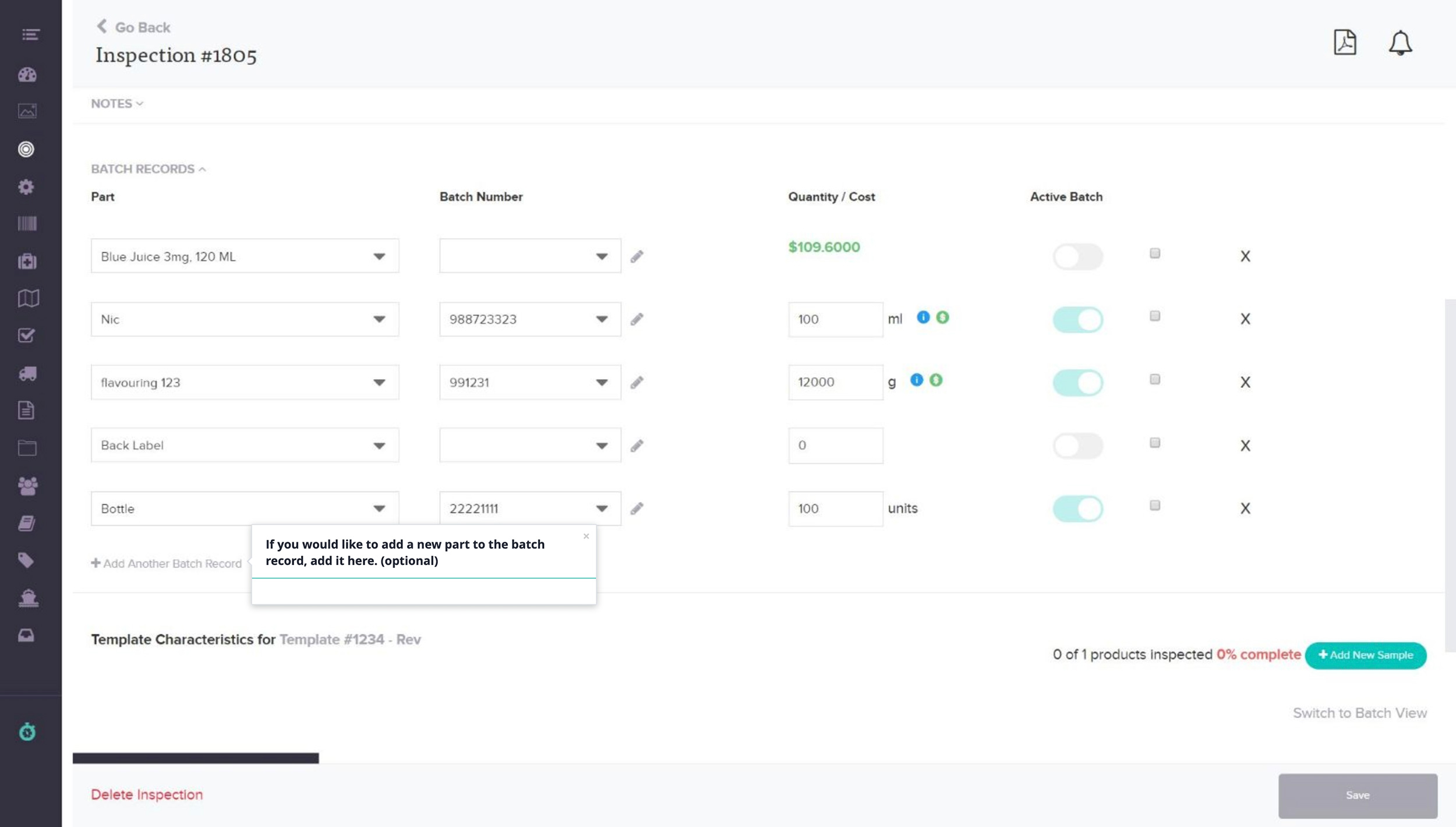

Step #36

If you would like to add a new part to the batch record, add it here. (optional)

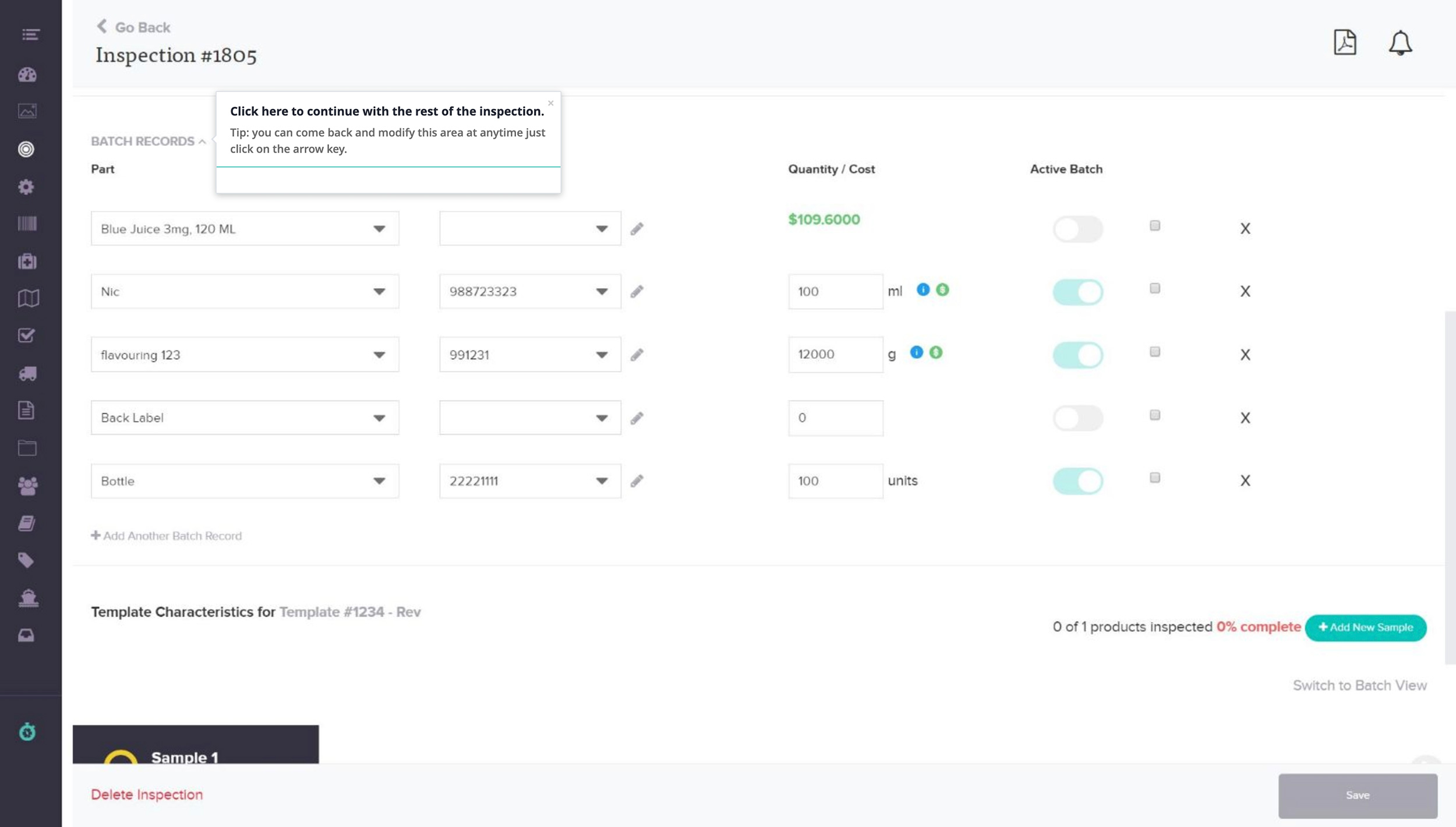

Step #37

Click here to continue with the rest of the inspection.

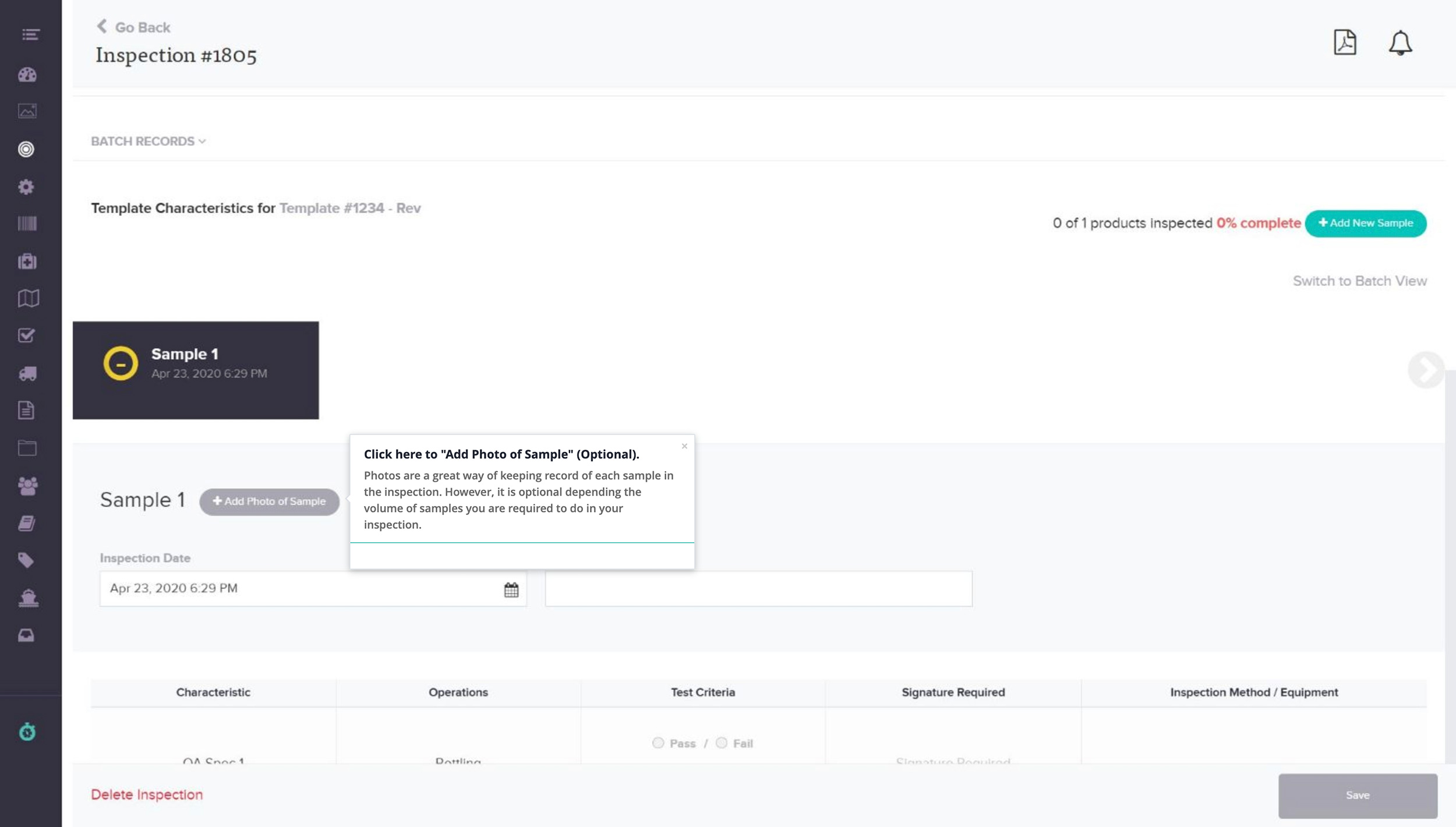

Step #38

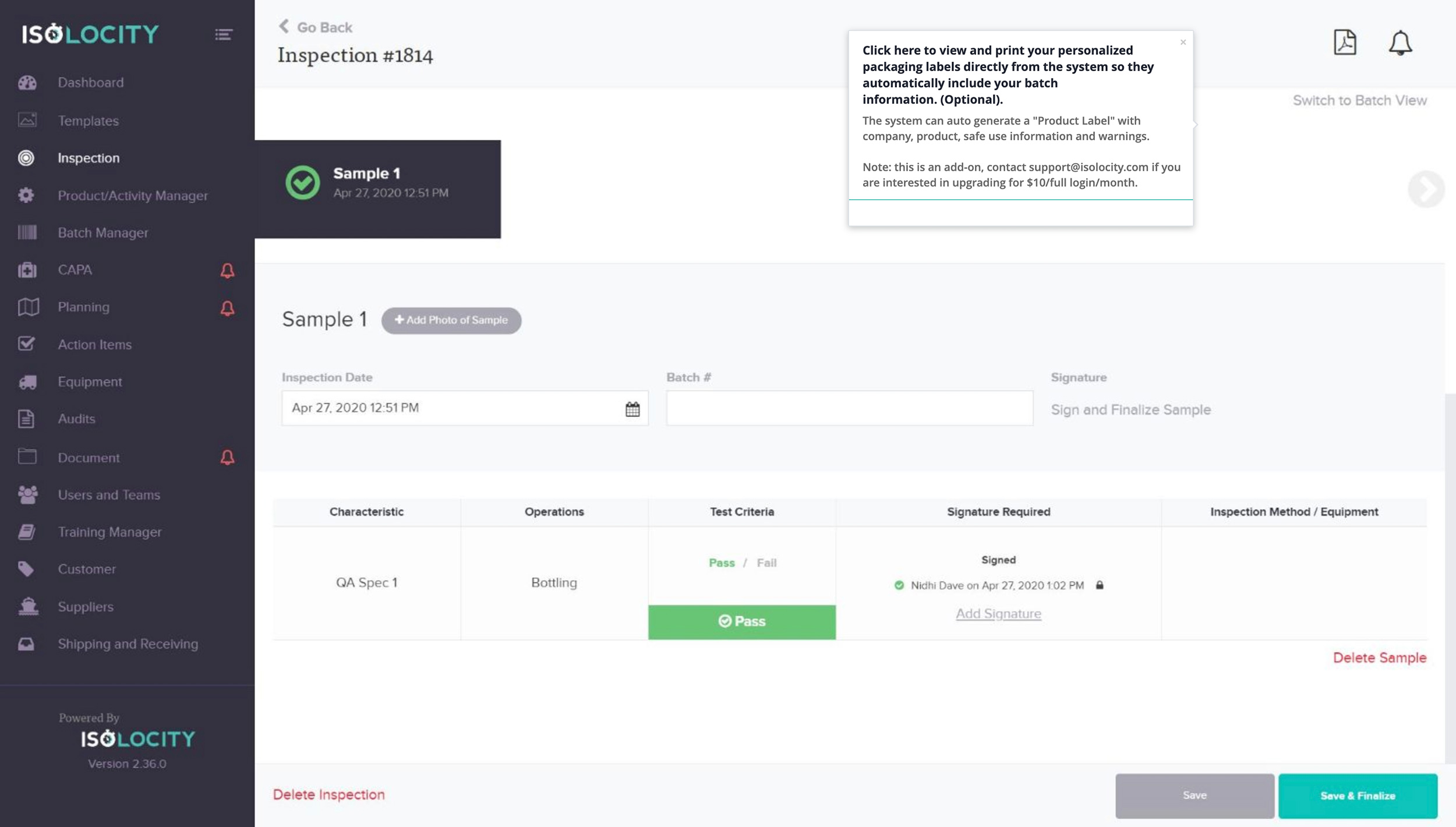

Click here to “Add Photo of Sample” (Optional).

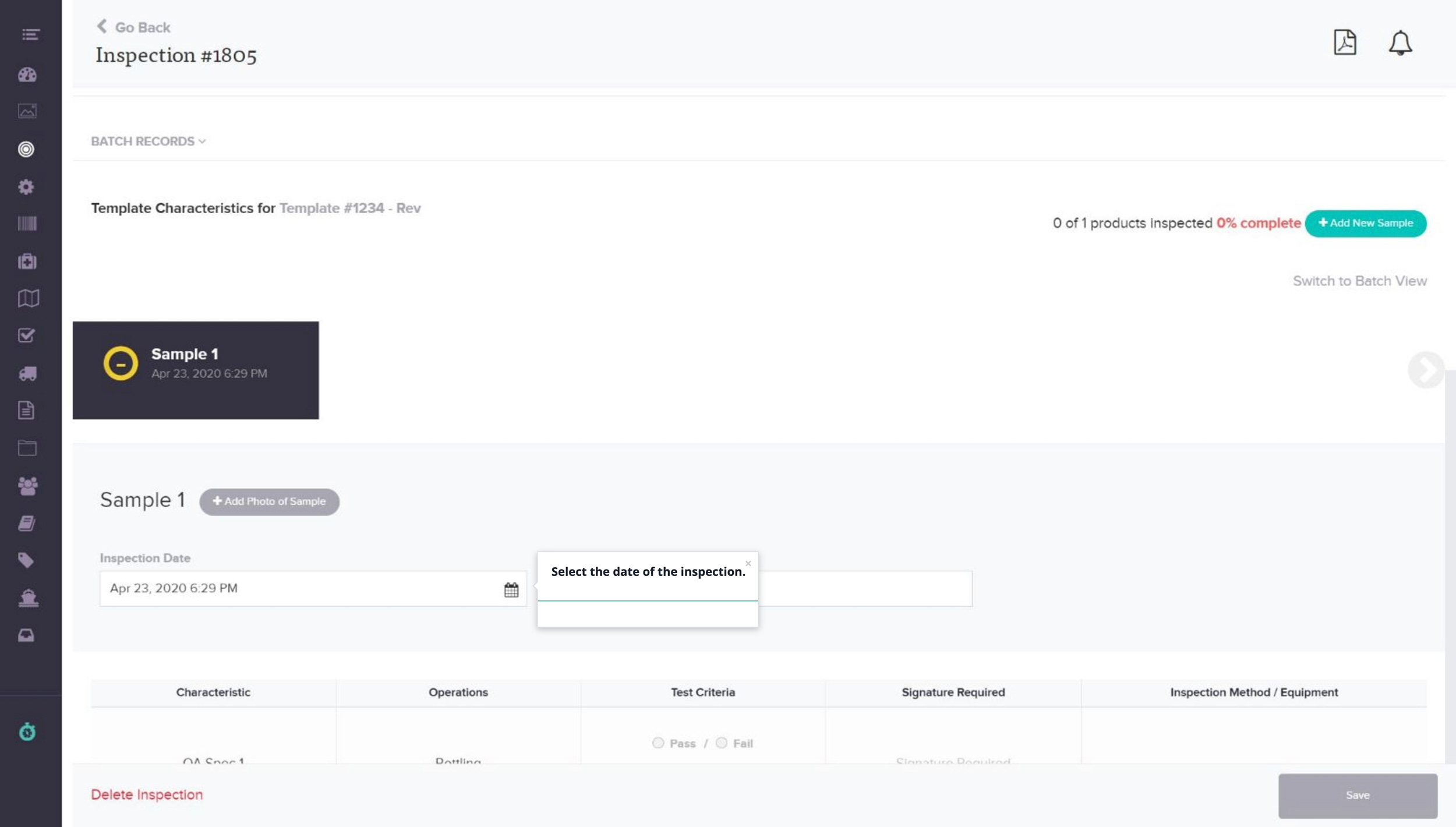

Step #39

Select the date of the inspection.

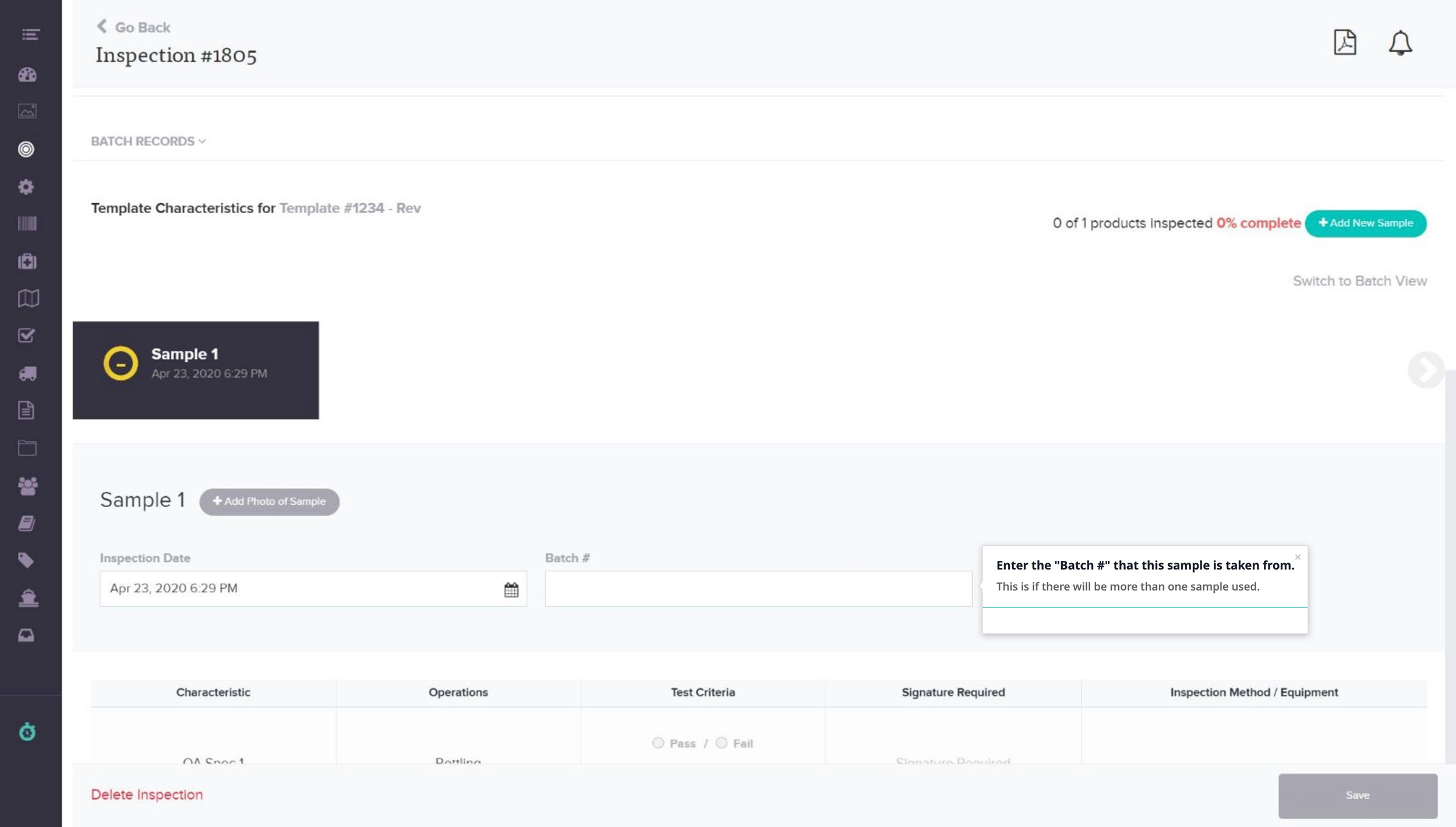

Step #40

Enter the “Batch #” that this sample is taken from.

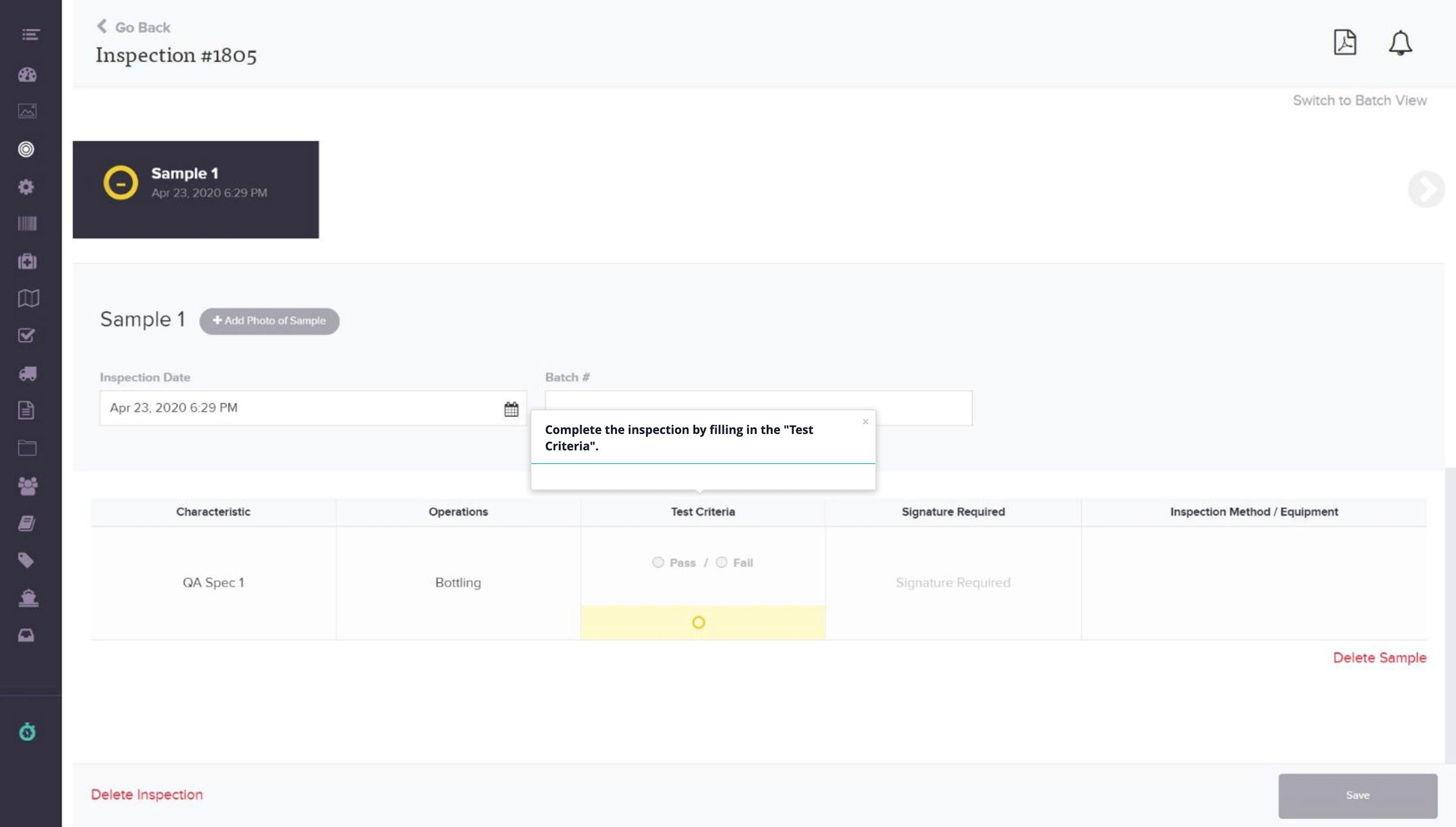

Step #41

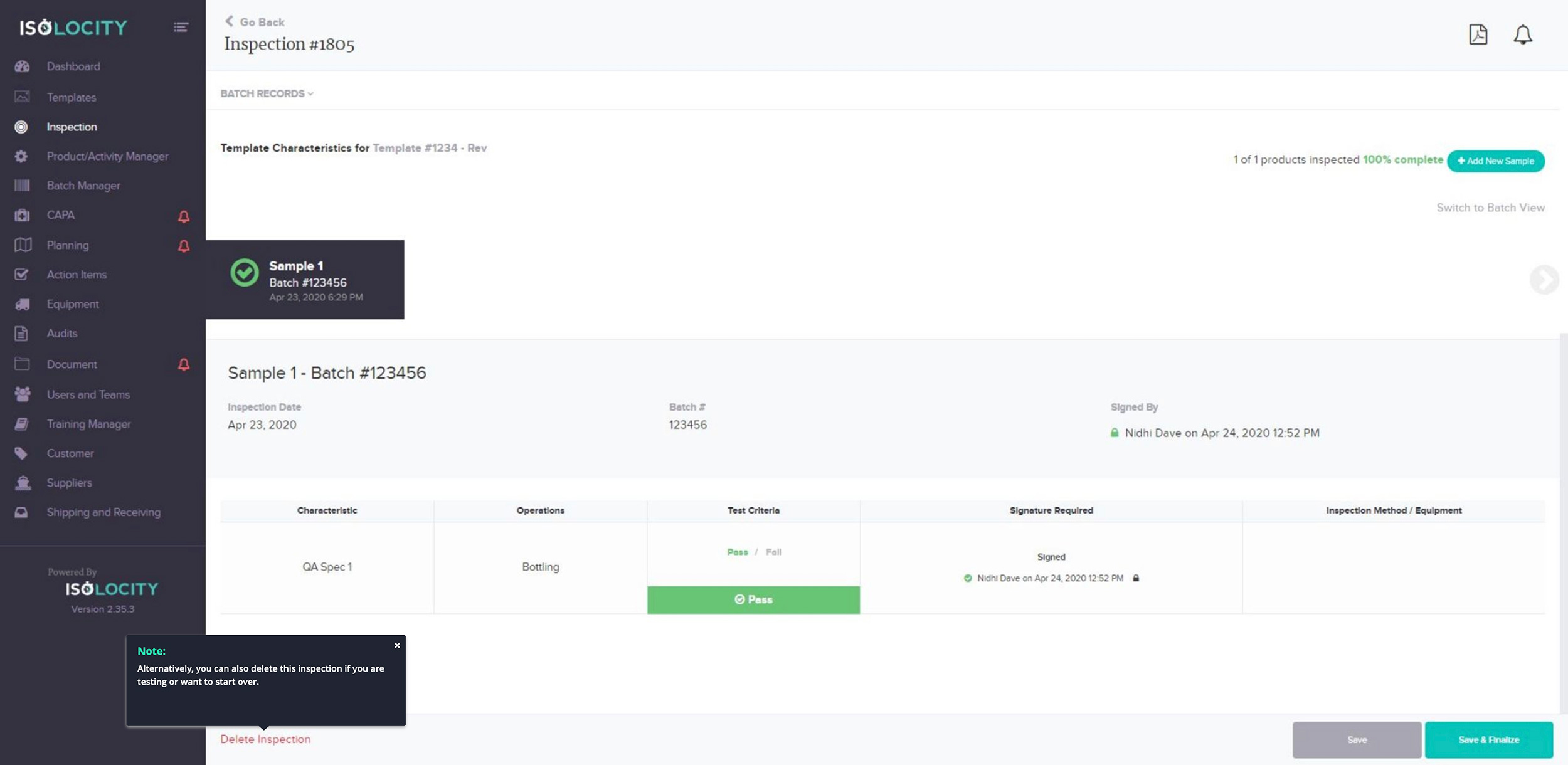

Complete the inspection by filling in the “Test Criteria”.

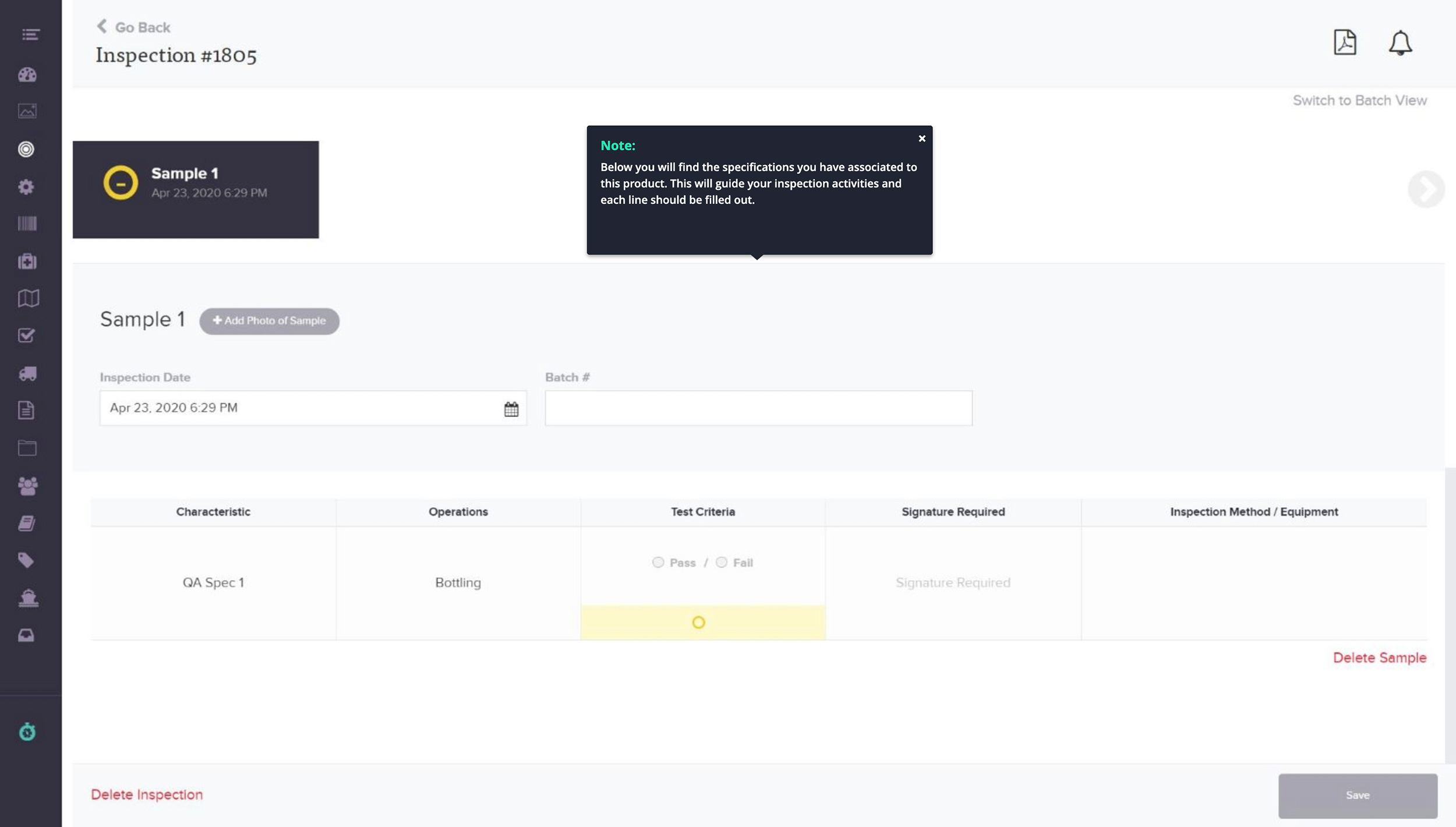

Step #42

Note

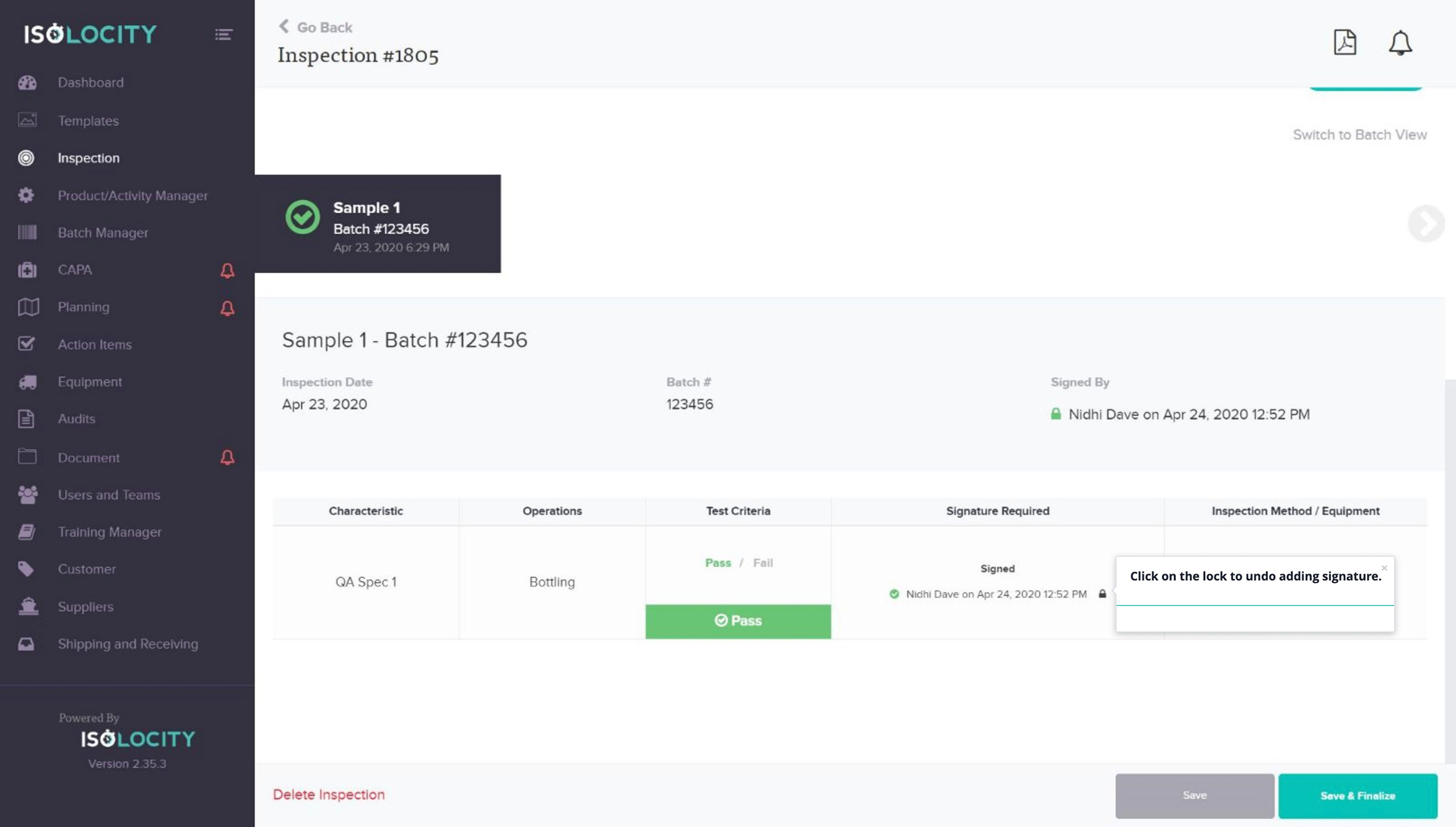

Step #43

Click on the lock to undo adding signature.

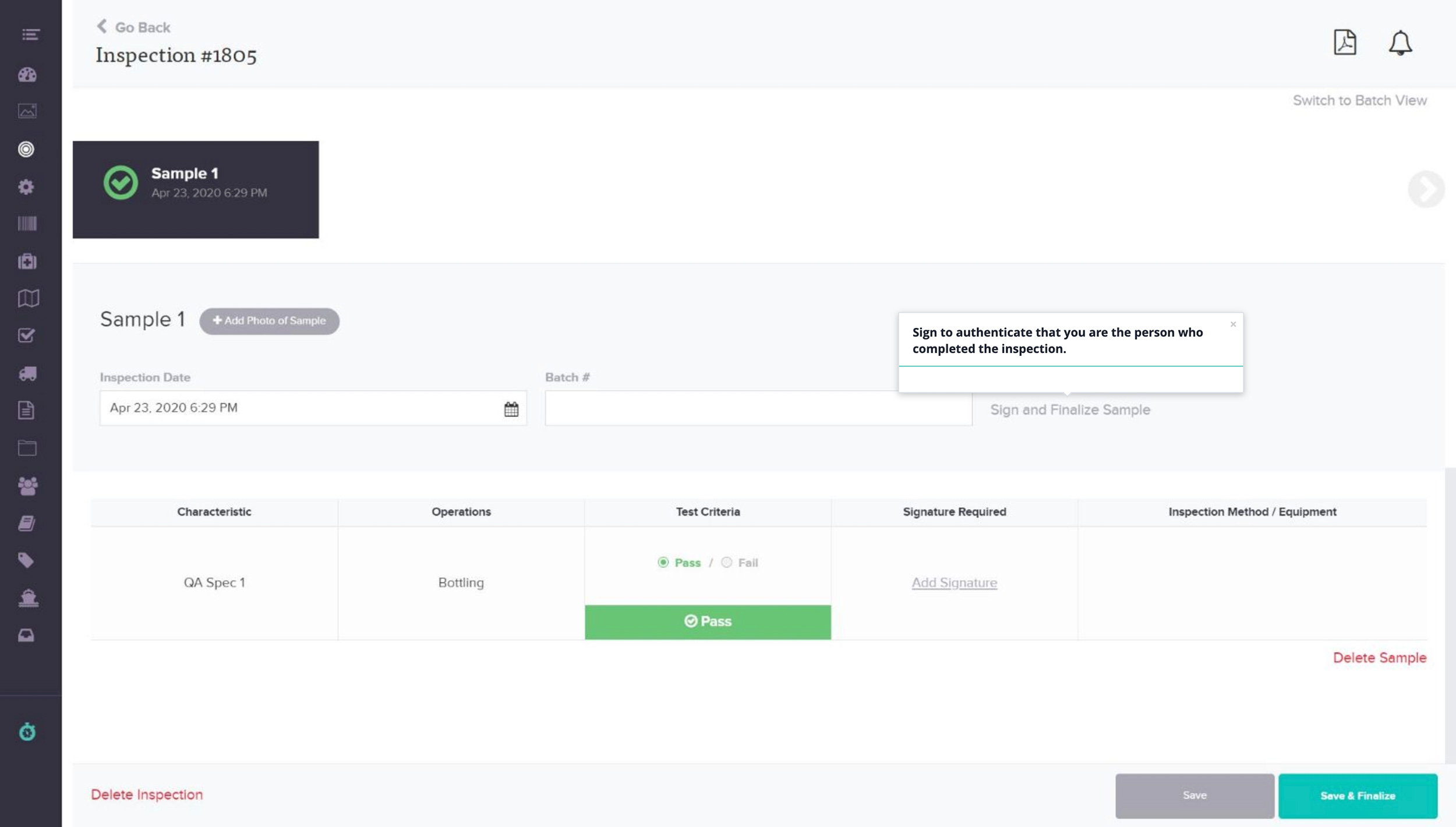

Step #44

Sign to authenticate that you are the person who completed the inspection.

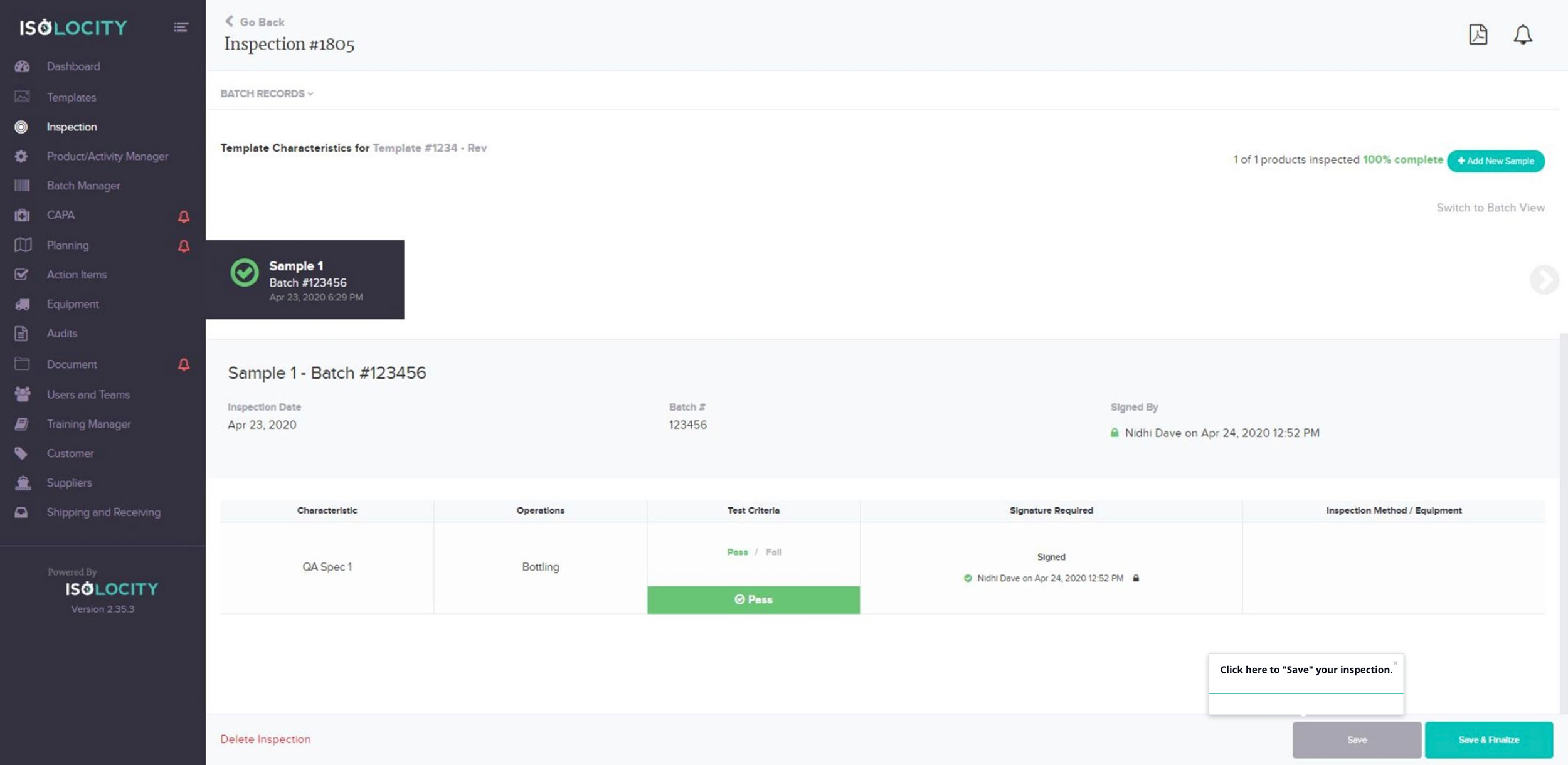

Step #45

Click here to “Save” your inspection.

Step #46

Note

Step #47

If the product Inspection has failed, it is possible to Initiate a Corrective Action Report or a Non-Conformance Report or an OOS Report.

Step #48

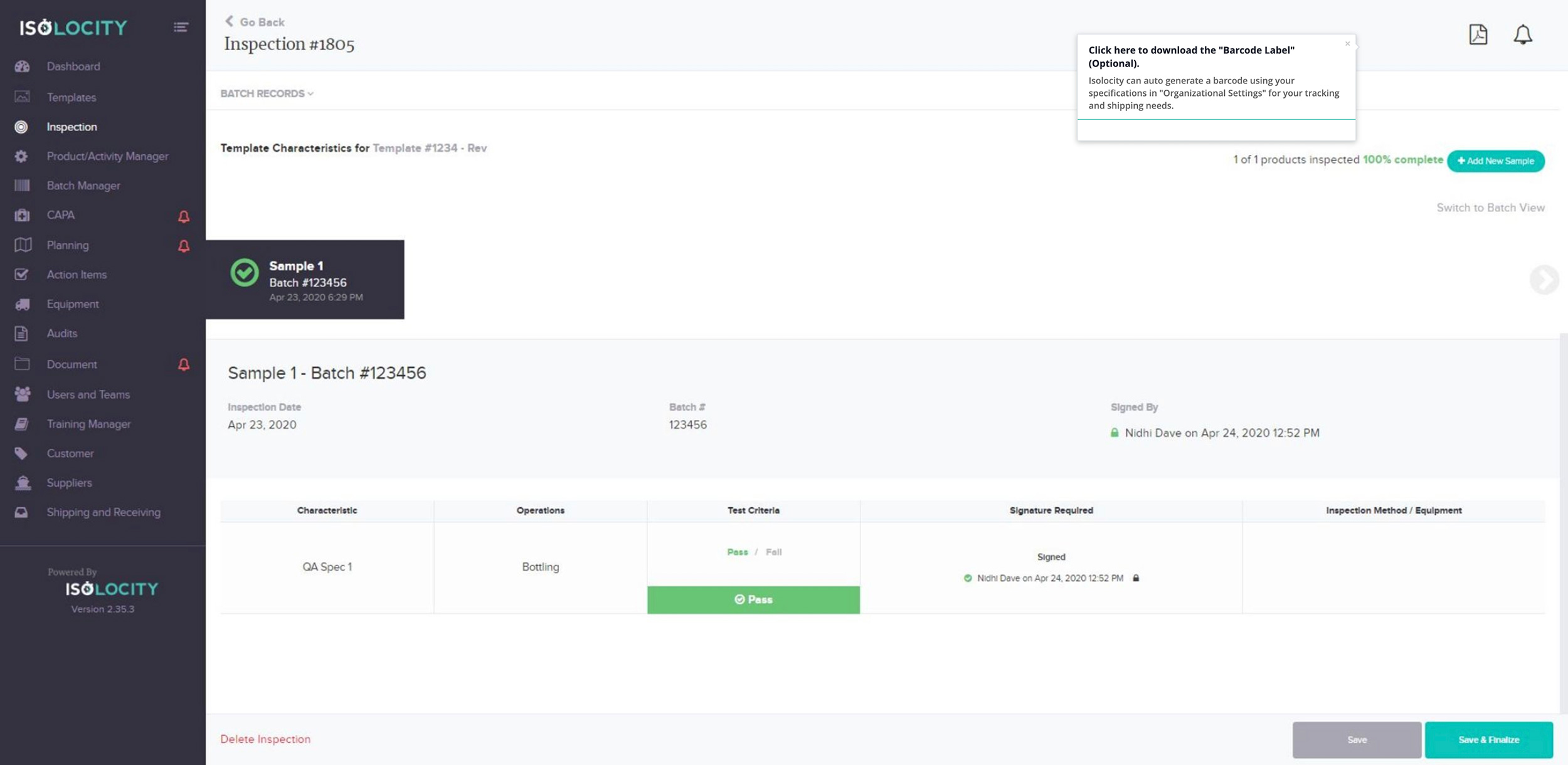

Click the PDF icon

Step #49

Click here to download the “Barcode Label” (Optional).

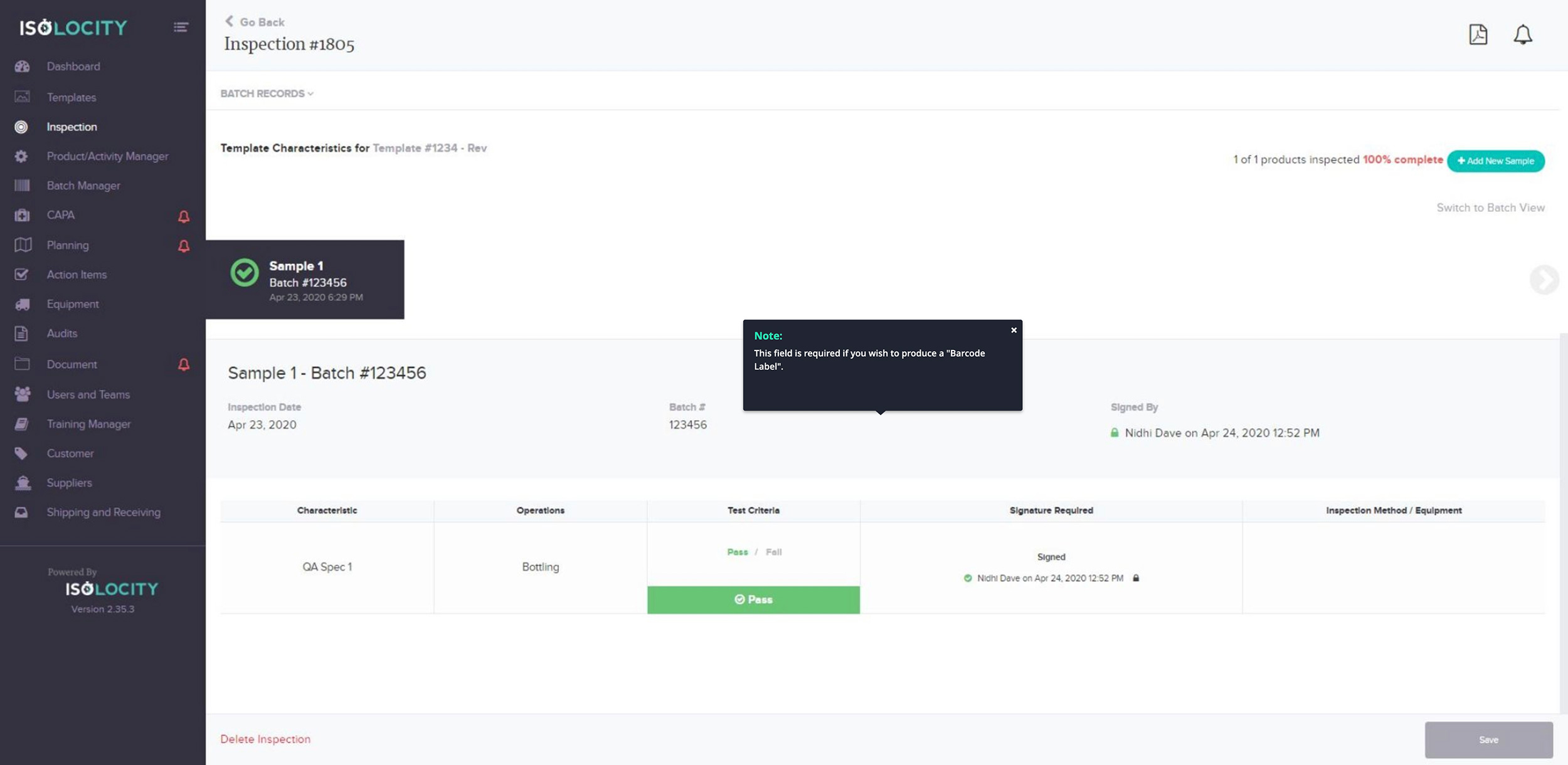

Step #50

Note

Step #51

Click here to view and print your personalized packaging labels directly from the system so they automatically include your batch information. (Optional).

Step #52

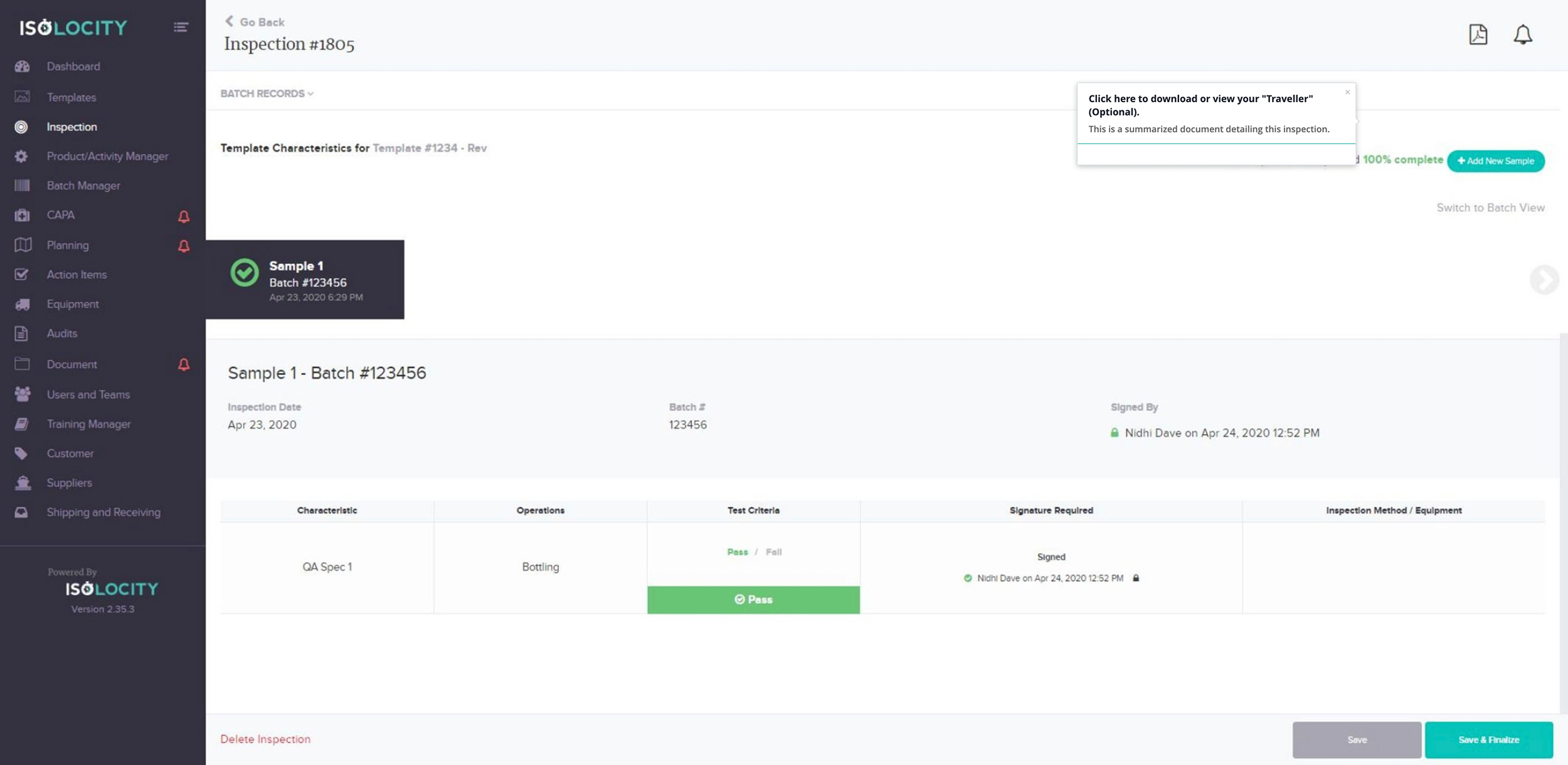

Click here to download or view your “Traveller” (Optional).

Step #53

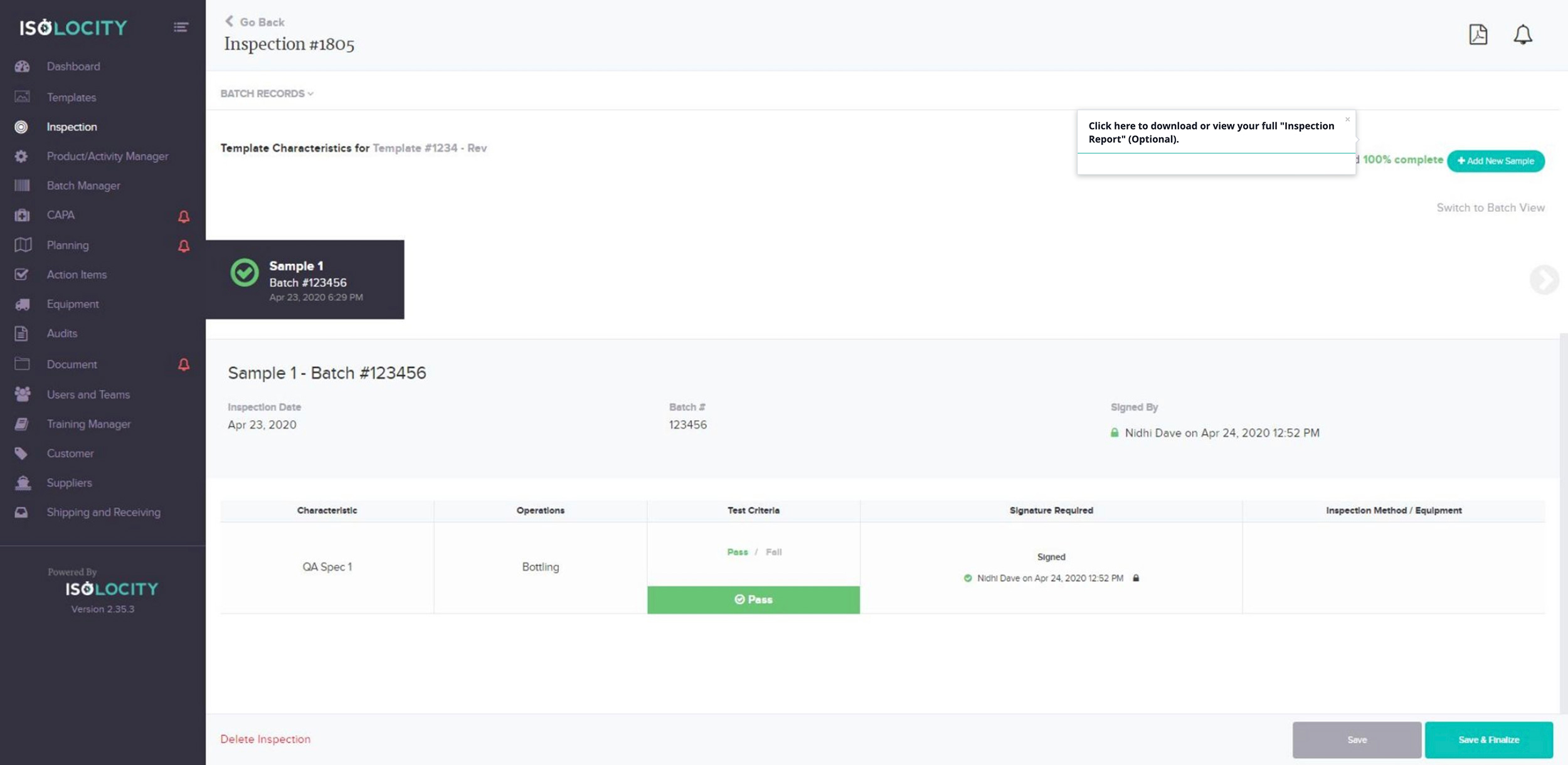

Click here to download or view your full “Inspection Report” (Optional).

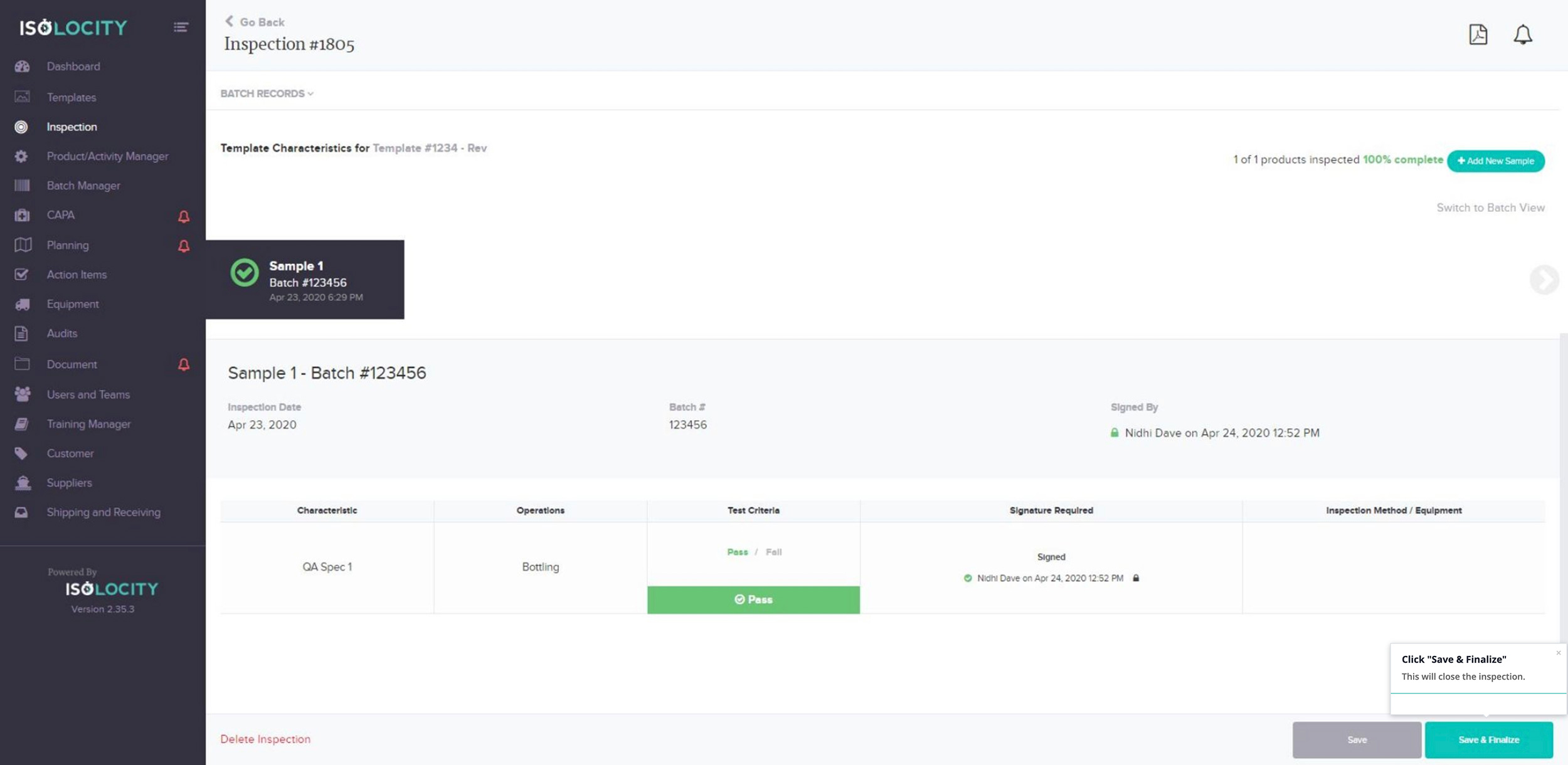

Step #54

Click “Add New Sample”

Step #55

Click “Save & Finalize”

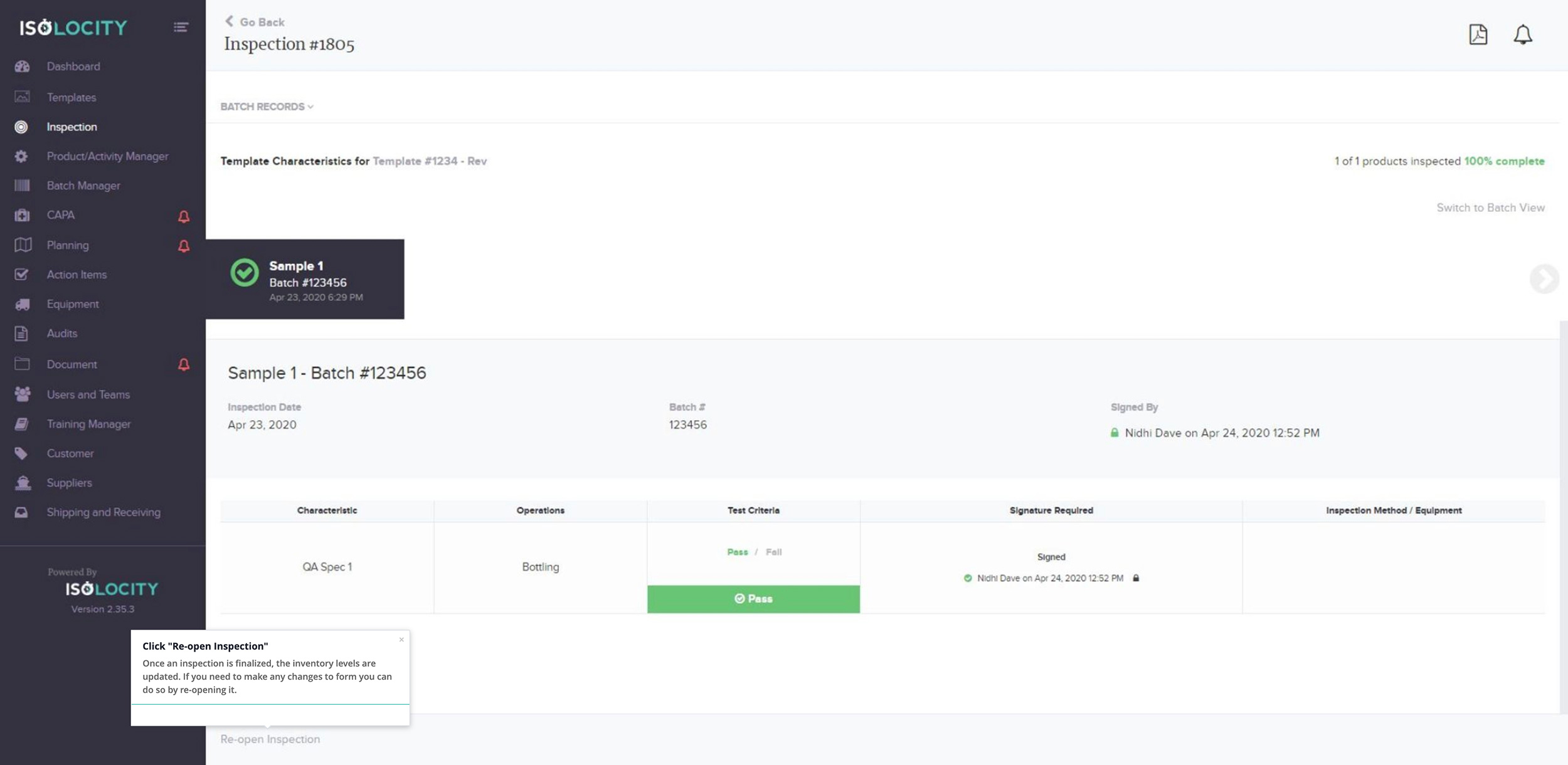

Step #56

Click “Re-open Inspection”

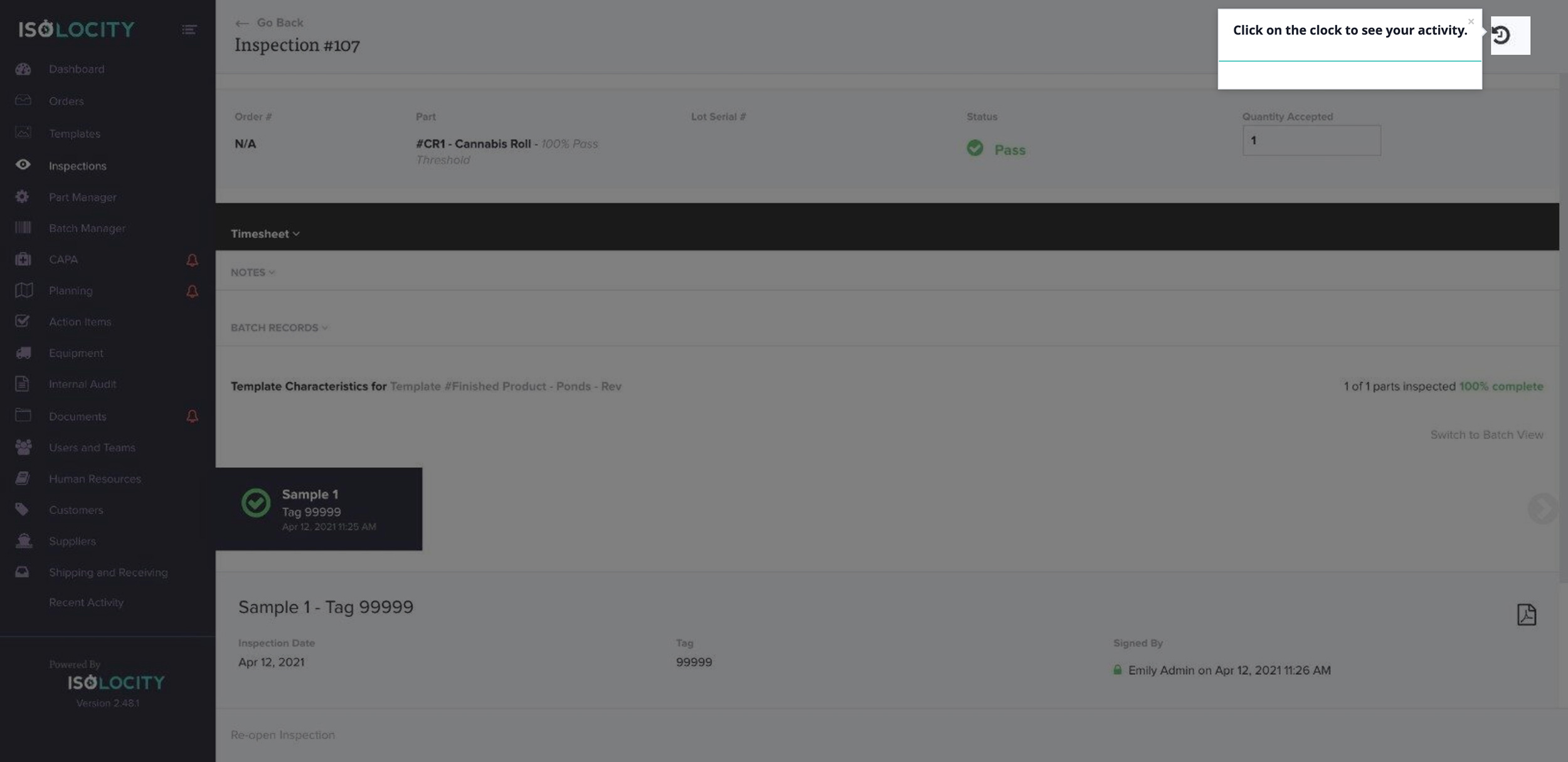

Step #57

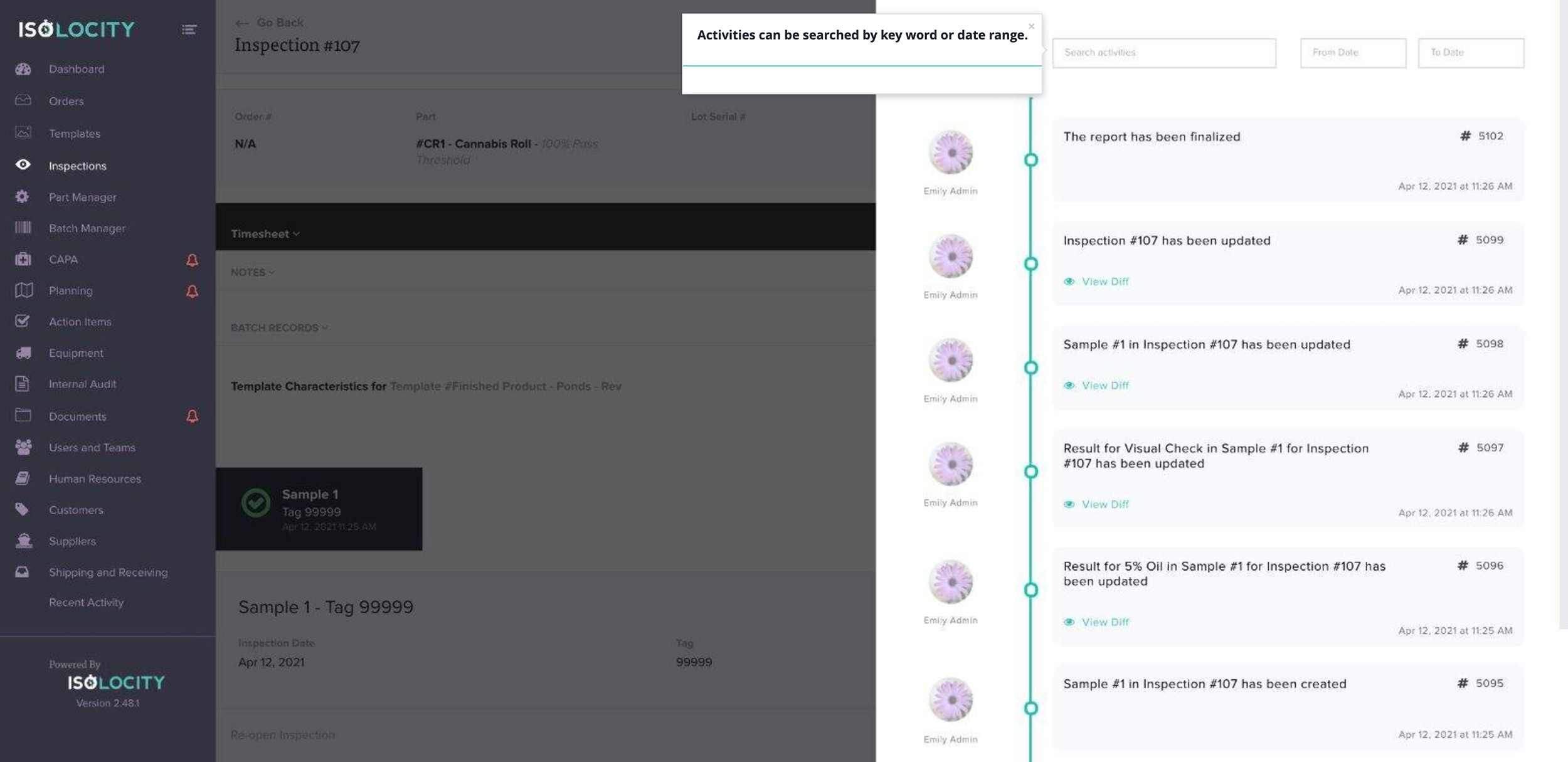

Click on the clock to see your activity.

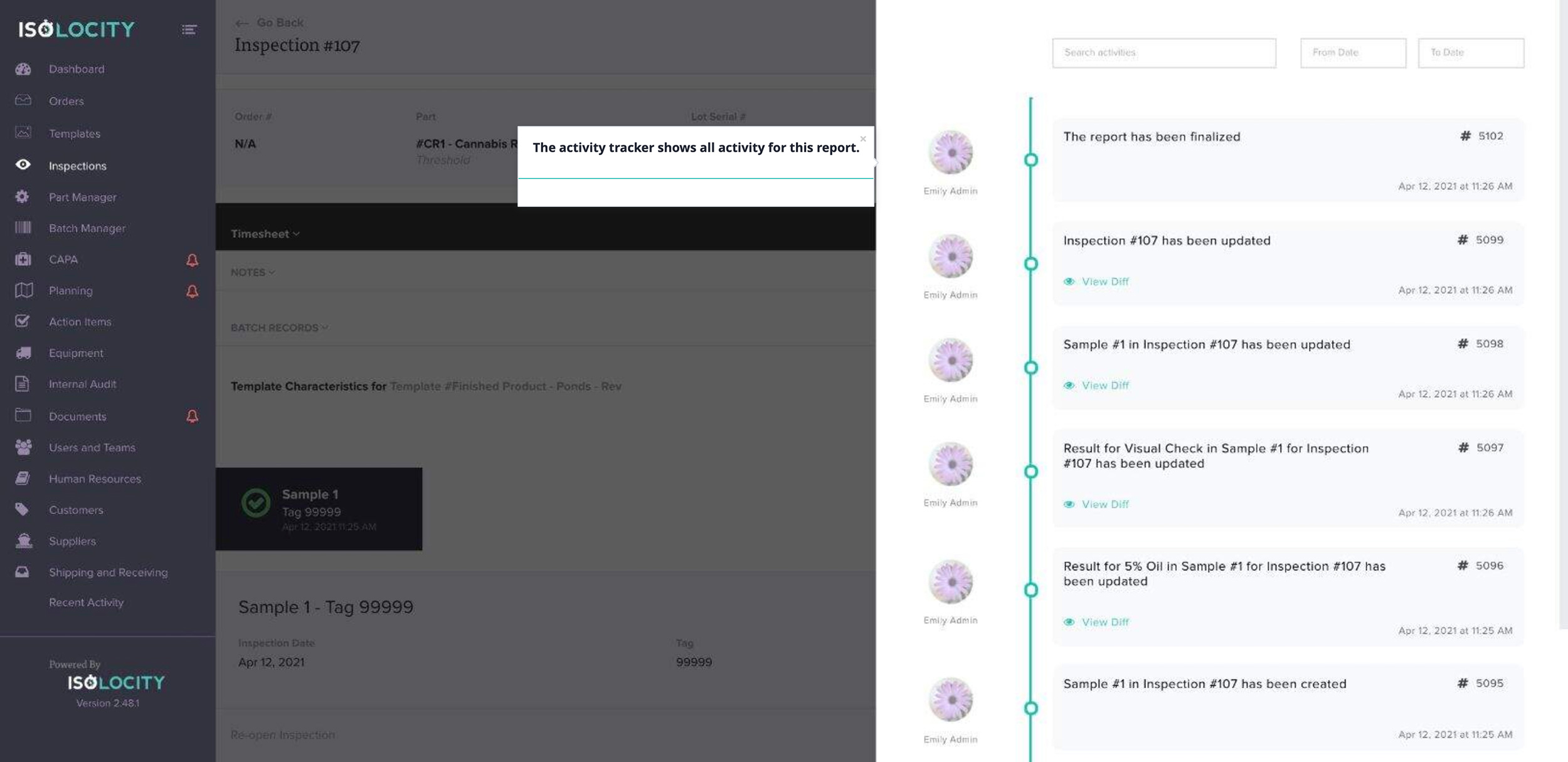

Step #58

The activity tracker shows all activity for this report.

Step #59

Activities can be searched by key word or date range.

Step #60

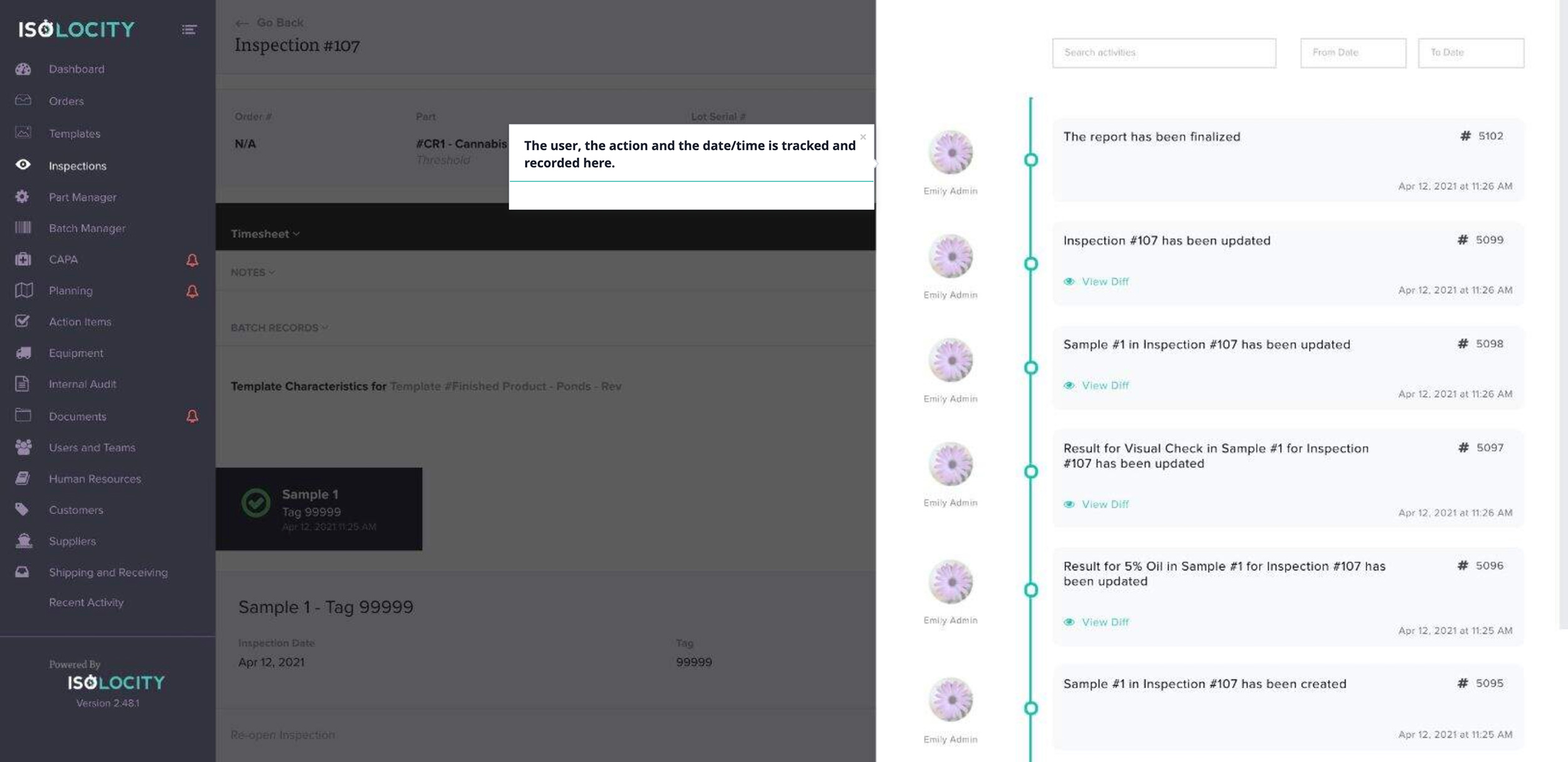

The user, the action and the date/time is tracked and recorded here.

Step #61

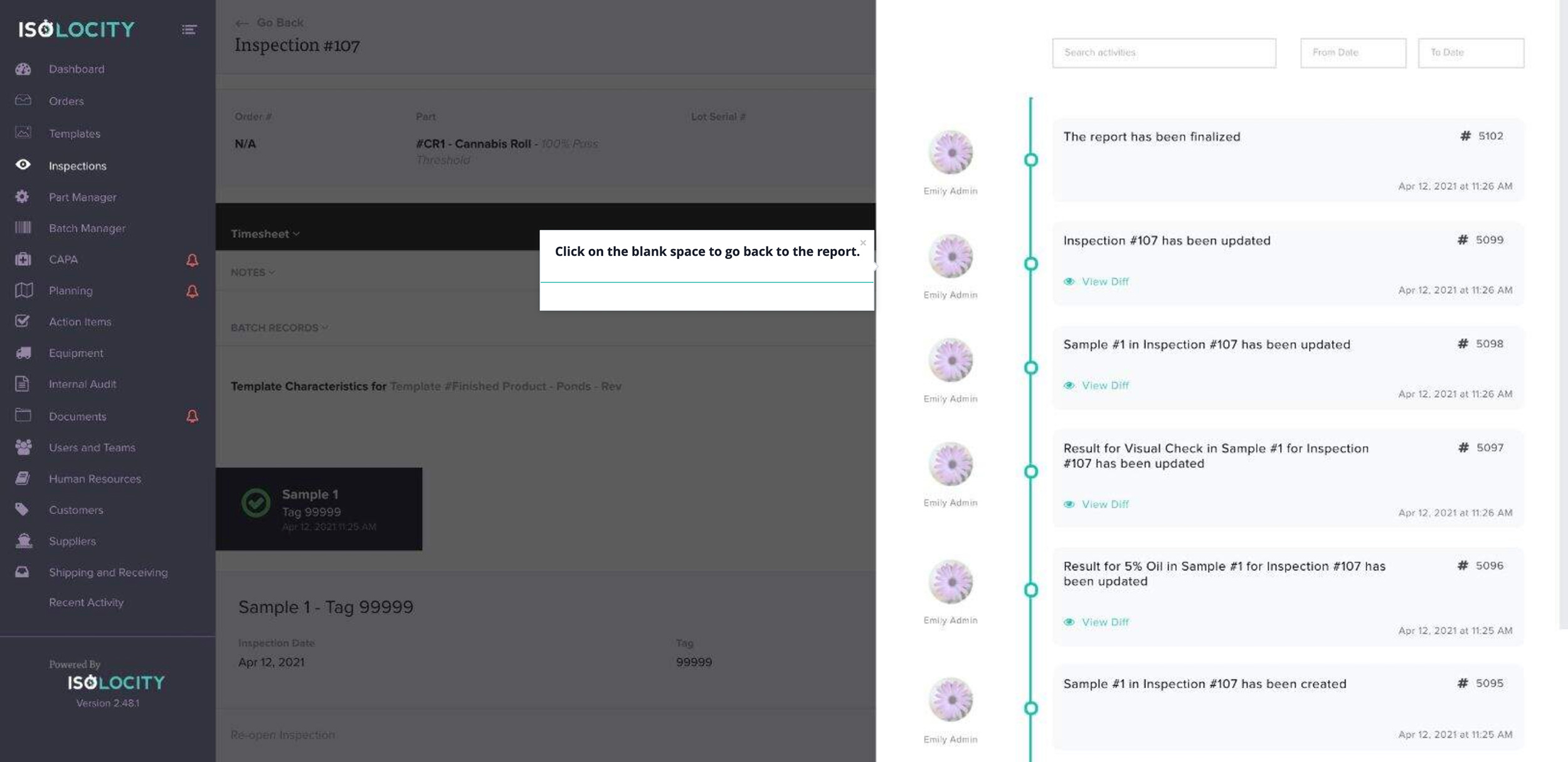

Click on the blank space to go back to the report.