You’ve probably noticed AI’s widespread impact across different industries. According to Similarweb, the global AI market is expected to hit $407 billion by 2027, growing at a whopping rate of 36.2% since 2022. This not only shows AI’s rising importance but also hints at big changes coming to quality management. We figured, why not whip up an article on AI QMS and spill the beans on what’s cooking at Isolocity?

Check out the video version of the blog below!

How is Isolocity taking advantage of AI?

We are using AI in the backend so that the frontend operations run smoothly. There’s a reason our users rated us 4.8 on Capterra, G2, Google, and other platforms. We maintain a high quality of data processing with AI. Thanks to AI, some of the data processing jobs that we used to do manually are now automated, and therefore we can move on to more pressing issues or product developments. Here’s one example of how we are using AI for Isolocity QMS.

1. Getting started:

We have a lot of forms from our clients, and we want to enter all the information from these forms into our software.

2. Using AI:

Instead of doing this manually, we’re using a smart tool called Google Cloud and their document AI. This tool can understand the information on the forms, almost like how a person would.

3. Training the AI:

Before the AI can help us, it needs to learn. So, we pick a few forms (let’s say 6 to start with) and upload them into the AI system. The AI then studies these forms to understand what’s written on them.

4. Learning what’s important:

The AI learns to recognize the key parts of the forms, like what’s the main thing being described (let’s call it the “operation”) and what specific details are mentioned (let’s call these the “characteristics”).

5. Improving accuracy:

The more similar forms we give to the AI, the better it gets at understanding them. It’s like teaching a child—practice makes perfect!

6. Using AI’s suggestions:

Once the AI has learned from the forms, it can give us suggestions on what parts of the form should go where in our software. For example, it might say, “Hey, this part of the form seems to describe the main operation. And this other part talks about specific characteristics.”

7. Putting forms into the system:

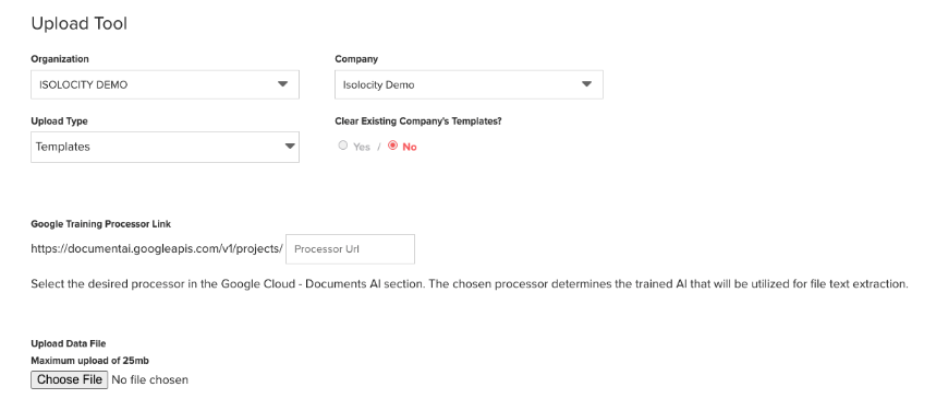

With the AI’s help, we can easily upload the forms into our system using a special tool in our admin panel. This tool automatically fills in details like the form’s name and ID, and it also puts the operation and characteristic information in the right places.

8. Auditing:

Before everything is finalized, we audit the information to ensure it’s correct.

So, in simple terms, we’re using an AI tool to understand and enter information from our client forms quickly and accurately.

Related section: Artificial Intelligence and Machine Learning

How is AI going to revolutionize the QMS industry?

In the realm of manufacturing, maintaining high-quality standards will become even more critical for delivering products that meet customer expectations and regulatory requirements. Looking ahead, artificial intelligence (AI) is poised to revolutionize this aspect of quality management within manufacturing factories, transforming the way data is collected and analyzed.

Here’s how AI will reshape data collection for quality management inside manufacturing facilities:

Automated Data Capture:

AI-powered sensors and IoT devices will automate the collection of data at various points along the production line. These sensors will gather information on parameters such as temperature, pressure, vibration, and machine performance in real-time. By automating data capture, AI will eliminate the need for manual intervention, reducing human error and ensuring data accuracy.

Check this article : AI-powered ‘frozen smoke’ sensors redefine formaldehyde detection.

Image copyright: cryptopolitan.com

Predictive Maintenance:

AI algorithms will analyze data from equipment sensors to predict potential machine failures or quality issues before they occur. By detecting patterns indicative of impending malfunctions, manufacturers will be able to schedule preventive maintenance tasks proactively, minimizing downtime and preventing production disruptions.

Quality Inspection Automation:

AI-driven computer vision systems will automate the inspection of manufactured parts and products. By analyzing images or videos of components, AI algorithms will identify defects, deviations from specifications, or anomalies in real-time. This automated inspection process will ensure consistent quality and reduce the reliance on manual inspection methods, which can be time-consuming and subjective.

Check this article: AI to Transform Quality Inspection Across Industries

Process Optimization:

AI-powered analytics platforms will analyze vast amounts of production data to identify inefficiencies and areas for improvement. By correlating process parameters with quality outcomes, AI algorithms will optimize manufacturing processes to enhance product quality, minimize waste, and maximize throughput. This data-driven approach to process optimization will enable manufacturers to achieve higher levels of efficiency and competitiveness.

Real-time Monitoring and Control:

AI systems will provide real-time monitoring and control capabilities, allowing manufacturers to intervene promptly in cases of quality deviations or process variations. By continuously analyzing incoming data streams, AI algorithms will detect abnormalities and trigger corrective actions to maintain product quality standards within predefined tolerances.

Continuous Improvement:

AI will facilitate a culture of continuous improvement by providing insights derived from historical and real-time data analysis. By identifying trends, root causes of defects, and opportunities for optimization, AI will empower manufacturers to implement corrective actions and drive ongoing quality enhancement initiatives.

Related section: Check out “Explore the Impact of AI on Manufacturing and Quality” in the “3 reasons to attend the Quality show south by Quality Magazine” blog.

Conclusion

The incorporation of AI into Quality Management Systems represents a significant milestone in the advancement of manufacturing operations. We’re diligently enhancing Isolocity QMS with additional AI-powered functionalities, aiming to optimize both our internal processes and enhance the experience for all our customers. Isolocity 3.0 introduces a plethora of innovative features, and our commitment to ongoing improvement ensures that we’re continuously refining the software to meet the evolving needs of our users.