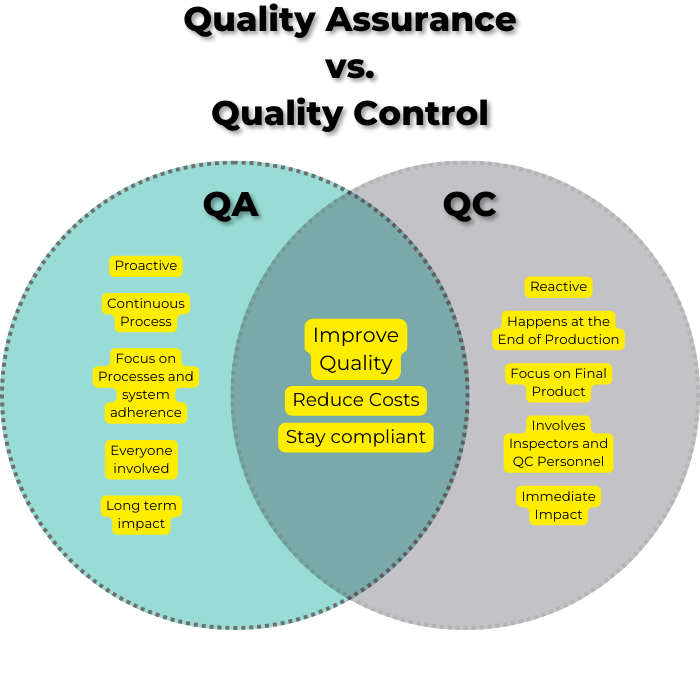

Quality Assurance vs. Quality Control (QA vs. QC) is a pivotal concept in the realm of quality management. The distinction is evident in their names: one assures quality proactively, while the other controls it reactively. A robust quality management system relies on the seamless collaboration of both approaches.

In this blog, we’ll delve into the intricacies of QA vs. QC. We’ll also address commonly asked questions. If you feel we’ve overlooked any queries, don’t hesitate to reach out to us. Stay tuned for a simplified yet professional exploration of this fundamental aspect of quality management.

Looking for a QMS that can help with both QA & QC? Talk to our product specialists.

Watch The Video on Quality Assurance vs. Quality Control

Quality Assurance (QA): Making sure things are perfect from the start

In the manufacturing world, quality assurance (QA) is the proactive force that shapes the whole production process and sets the stage for success.

Process Planning and Documentation:

Picture a factory that makes very precise machines. QA involves carefully planning and writing down every step of the manufacturing process, from choosing the raw materials to putting them together. These detailed plans become the foundation of quality, making sure that all output is the same.

Training and Skill Development:

In this case, QA includes training and skill development for the business. Imagine a team that is not only good at running machines but also good at fixing problems and always getting better. Skill development based on quality assurance cuts down on mistakes and promotes a quality mindset.

Improve All the Time:

Quality assurance (QA) encourages a mindset of always getting better in manufacturing settings. Think of an assembly line for electronics. Regular checks and ways for workers to give comments help make the processes better. This iterative method makes sure that the final goods always meet or beat strict quality standards.

Quality Control (QC): The Fine-Tuned Inspector

In the manufacturing industry, QC is the thorough inspector. Quality control makes sure that the finished goods meet the quality standards that have already been set.

Inspection and Testing:

Picture a line of people making electrical parts. QC includes carefully checking and testing every batch to make sure that the parts meet the exact requirements. Sample testing acts as a guardrail to keep low-quality goods from getting into the market.

Defect Identification and Correction:

On an assembly line for cars, QC means finding and fixing problems with the cars before they go on sale. This method includes thorough inspections, and any problems that happen that aren’t in line with design or production standards are quickly fixed.

Verification of Compliance:

In manufacturing, QC checks to see if rules are being followed. In a plant that makes medicines, for example, quality control makes sure that each batch meets the rules so that the end product is safe and works well.

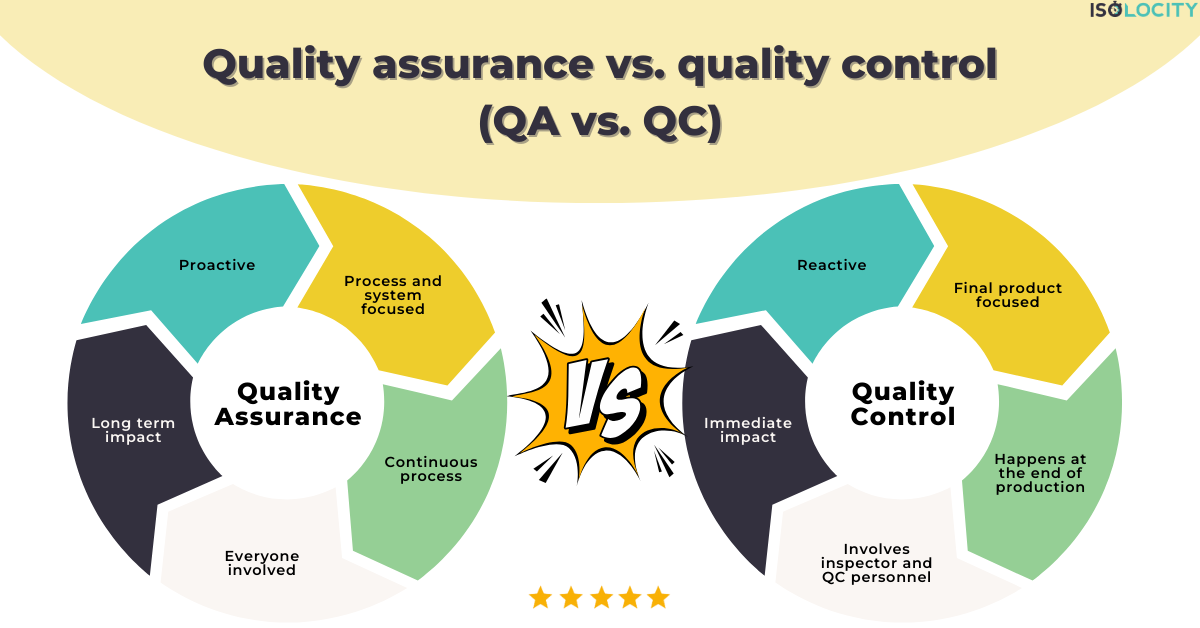

Quality Assurance vs. Quality Control: 8 Key Differences

After seeing how QA and QC work in the business world, let’s look more closely at the differences between them.

1. Focus:

QA is proactive, aiming to prevent defects before they occur by ensuring adherence to established processes and standards.

QC is reactive, focusing on the detection and correction of defects after production, primarily centered on verifying that the final product meets specified requirements.

Related blog post: How to Master Quality Control with One Piece Flow?

2. Timing:

QA activities occur throughout the entire production process, from planning to execution, to ensure that processes are followed correctly.

QC activities typically occur at the end of the production process when the final product is ready for inspection and testing.

3. Objective:

QA’s objective is to ensure adherence to established processes and standards, aiming for consistency and reliability in the production process.

QC’s objective is to verify that the final product meets specified requirements and is free from defects before it is released to customers.

Related blog post: Cannabis Quality Control – A Complete Guide

4. Activities:

QA activities include process planning, documentation, training, and continuous improvement efforts to establish and maintain robust processes.

QC activities include inspection, testing, defect identification, and correction to ensure that the final product meets quality standards.

5. Nature of Inspection:

QA inspection focuses on processes and system adherence, ensuring that the production process is following established protocols.

QC inspection focuses on the final product or output, examining it for defects or deviations from specifications.

Related blog post: The Essential Guide to Part Inspection and Product Inspection in Manufacturing

6. Involvement:

QA involves everyone in the organization, from top management to frontline workers, as it is concerned with establishing and maintaining quality processes.

QC primarily involves inspectors and quality control personnel who are responsible for inspecting and testing the final product.

7. Timeline Impact:

QA has a long-term impact on the entire production process by establishing robust processes that prevent defects over time.

QC has an immediate impact on the specific batch or product being inspected, ensuring that defects are detected and corrected before they reach customers.

8. Goal:

The goal of QA is to prevent defects by establishing and maintaining robust processes and systems.

The goal of QC is to detect and correct defects to ensure the quality of the final product before it is delivered to customers.

QA vs. QC: Tabular Format

| Aspect | Quality Assurance (QA) | Quality Control (QC) |

| Focus | Proactive: Prevention of defects before they occur | Reactive: Detection and correction of defects after production |

| Timing | Throughout the entire production process | At the end of the production process |

| Objective | Ensure adherence to established processes and standards | Verify that the final product meets specified requirements |

| Activities | Process planning, documentation, training, and continuous improvement | Inspection, testing, defect identification, and correction |

| Nature of Inspection | Focuses on processes and system adherence | Focuses on the final product or output |

| Involvement | Involves everyone in the organization, from top management to frontline workers | Primarily involves inspectors and quality control personnel |

| Timeline Impact | Long-term impact on the entire production process | Immediate impact on the specific batch or product |

| Goal | To prevent defects by establishing robust processes | To detect and correct defects to ensure product quality |

“In the symphony of production, Quality Assurance orchestrates the composition, setting the stage for a flawless performance, while Quality Control, the vigilant conductor, ensures every note resonates with perfection.” – Chris Budd, Subject Matter Expert, Isolocity

QA vs. QC: Frequently Asked Questions

-

Can QA and QC be used separately in manufacturing?

As you can see, QA and QC do different things, but in production, they work well together. Often, both prevention and detection are built into a full quality control system.

-

Question: How important is QA in manufacturing?

QA is an important part of business. It sets the standard for quality by creating strong processes, making sure they are always the same, and encouraging a mindset of always getting better.

-

Which comes first, QA or QC?

Quality Assurance (QA) precedes Quality Control (QC). QA involves proactive measures to prevent defects, while QC focuses on reactive processes such as testing and inspection.

-

What is the difference between system QA and parts QC?

System QA ensures overall product quality, emphasizing processes, and standards. In contrast, Parts QC involves inspecting and testing individual components to address defects before integration.

-

What is the difference between QA and QE?

QA stands for “Quality Assurance,” which is a broad name for the whole process of quality management. QE, on the other hand, uses modern techniques to improve product quality, such as test automation and continuous integration.

-

Is QC higher than QA?

Traditionally, QA is considered higher than QC, as it focuses on proactive defect prevention. However, in modern quality management, both QA and QC are complementary processes.

-

Why move from QC to QA?

Transitioning from QC to QA is a strategic shift towards a proactive quality management approach. QA prevents defects, improving efficiency and reducing the need for extensive testing and rework.

-

Can you have QA without QC?

While QA can exist without QC in theory, incorporating both ensures a balanced quality management system, with QA focusing on process improvement and QC on defect detection and correction.

-

Is QA a test, or QC?

QA is not a test; it’s a set of proactive processes ensuring effective development and implementation. QC, on the other hand, involves testing and inspection for defect identification and correction, both essential for quality management.

Conclusion: Question: It’s not QA vs. QC; it’s rather QA & QC

Both must work together well for quality excellence. When manufacturing companies put money into proactive quality assurance (QA) methods and thorough quality control (QC) checks, they build a strong foundation for consistently delivering high-quality products. Accepting both QA and QC is the only way to get to the highest level of quality in the manufacturing business.

Rate us on Capterra