Ensuring quality is crucial in all aspects of life. Whether it’s purchasing furniture or booking a hotel, we all seek products and services that meet certain standards. However, when it comes to food, quality management and contamination management are non-negotiable. The implications could be dire, and are often accompanied by a nasty FDA visit.

Because of this greater focus on quality, businesses seek Safe Quality Food (SQF) certification. Getting SQF approval is a real sign that a company is dedicated to maintaining food safety and quality. Throughout the production process, this promise is kept.

Today, we’ll delve into the 3 principles of the SQF certification, which include:

- Food safety fundamentals

- Prerequisite Programs

- HACCP

So let’s dive deeper into these 3 principles of SQF certification.

If You Prefer Video over Text, Check This Out!

1. Food Safety Fundamentals

Firstly, SQF accreditation is contingent upon the effective execution of comprehensive food safety principles. This involves creating and documenting a comprehensive Food Safety Management System (FSMS) tailored to the organization’s specific procedures. According to research findings published in Food Safety Magazine, the adoption of Food Safety Management Systems (FSMS) resulted in a noteworthy rise in the proportion of companies adhering to international standards, both in developed (from 16.7% to 63.9%) and developing countries (from 26.6% to 48.1%). Additionally, certification rates saw a substantial increase overall, climbing from 34.2% to 59.6%.

- Hazard Analysis and Risk Assessment: Hazard analysis and risk assessment are of the utmost importance in the identification and evaluation of potential dangers. For example, scholarly investigations suggest that epidemics of foodborne illnesses are frequently caused by microbial contamination.

- Documented Procedures and Policies: Documented policies and procedures are essential for demonstrating compliance. As per the article shared by FSNS, absence or poor documentation is one of the main reasons for SQF Audit Non-Conformity.

- Training and Education: Providing training and education to employees regarding food safety practices should be a major priority for any organization.

2. PRPs (Prerequisite Programs)

Prerequisite courses establish the groundwork for a sanitary manufacturing setting.

- Sanitation Practices: The implementation of rigorous sanitation protocols substantially decreases contamination incidents.

- Personnel hygiene: Personnel hygiene is an essential aspect that must be maintained. A substantial proportion of foodborne illness outbreaks implicate poor personal protection equipment.

- Facility maintenance: Facility maintenance plays a crucial role in mitigating equipment-related risks through a routine and sustainable schedule.

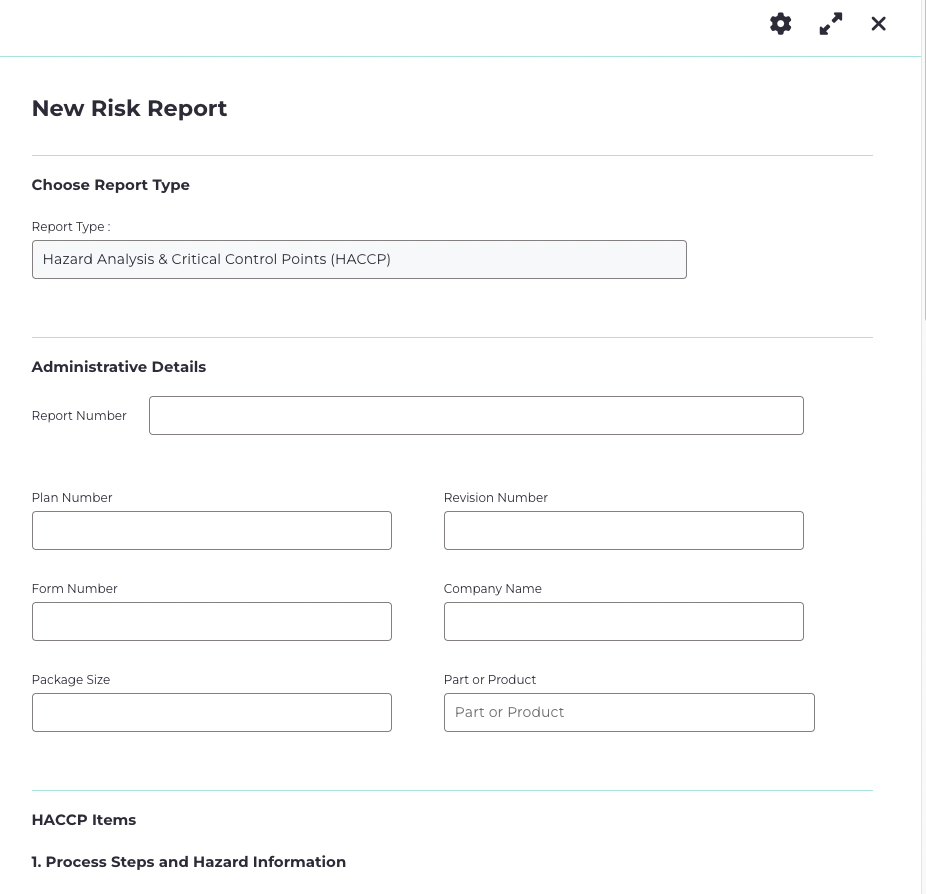

3. Hazard Assessment and Critical Control Points (HACCP)

HACCP is an approach to systematically identifying and managing hazards. In the United States alone, the implementation of HACCP resulted in a 20% reduction in foodborne illness over the seven years following its adoption, as shared by the National Library of Medicine.

- Hazard Analysis: An exhaustive hazard analysis significantly reduced contamination incidents. These include biological, chemical, physical, and other hazards.

- Critical control points (CCPs): Critical control points (CCPs) are critical locations where control measures must be implemented. According to research, monitoring CCPs substantially reduces the risk of foodborne illness.

- Monitoring and Verification: Consistent surveillance guarantees the continued efficacy of control measures.

Collaborating with Isolocity to Achieve Mastery of SQF Certification

Having clarified the SQF certification principles, we shall now examine the potential transformative impact that Isolocity could have on Food safety companies. To know about our food safety management capabilities, do check the food safety page on our website.

An all-encompassing food safety management system

Firstly, Isolocity offers a holistic solution tailored to address the distinct requirements for organizations seeking SQF certification. Isolocity renders SQF compliance more manageable by facilitating the implementation of FSMS through its intuitive interface and sophisticated functionalities.

Established an alliance with Safe Food Registrars

Our strategic partnerships with safe food registrars enable our clients to have a smooth and friendly transition to certification. Isolocity is third party reviewed, thus providing our clients with peace of mind knowing that we adhere to the most stringent standards in the industry regarding food safety and quality management.

Simplifying the Implementation of HACCP

The streamlined HACCP implementation made possible by the intuitive software of Isolocity enables organizations to effortlessly navigate the complexities of hazard analysis and control measures. Isolocity expedites the attainment of SQF certification by furnishing a centralized platform for the surveillance of critical control points and continuous verification operations.

Conclusion

In summary, achieving SQF certification encompasses more than just understanding regulatory obligations; it mandates the protection of consumer well-being and the cultivation of brand credibility. By leveraging Isolocity’s inventive solutions, SQF certification becomes an achievable milestone while fostering a safe food production culture that prioritizes quality and consumer protection. We’re excited to participate in the upcoming SQF Unites in New Orleans and look forward to meeting you there!

Should you be attending SQF Unites, we’d welcome the opportunity to engage in conversation and explore potential synergies between our organizations.