DMAIC is a popular problem-solving methodology used in Six Sigma. It provides a structured process for Six Sigma implementation and is very popular among quality management professionals. In this blog, we will be discussing the 5 phases of DMAIC. They are: define, measure, analyze, improve, and control.

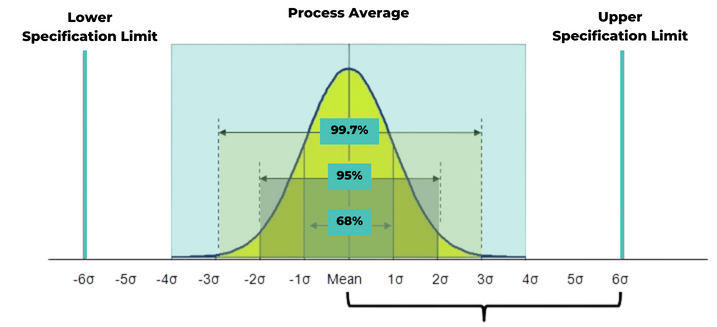

Six Sigma is coined from the idea that the standard deviation (Sigma) is so small that six standard deviations can fit on either side of a bell-shaped curve, indicating high precision. In defect terms, 6 Sigma equals merely 3.4 defects per million opportunities.

Prefer Video Over Text? Check This Out!

DMAIC is integral to the Six Sigma methodology. They are designed to enhance processes and minimize errors. Now, let’s delve into the 5 phases of DMAIC.

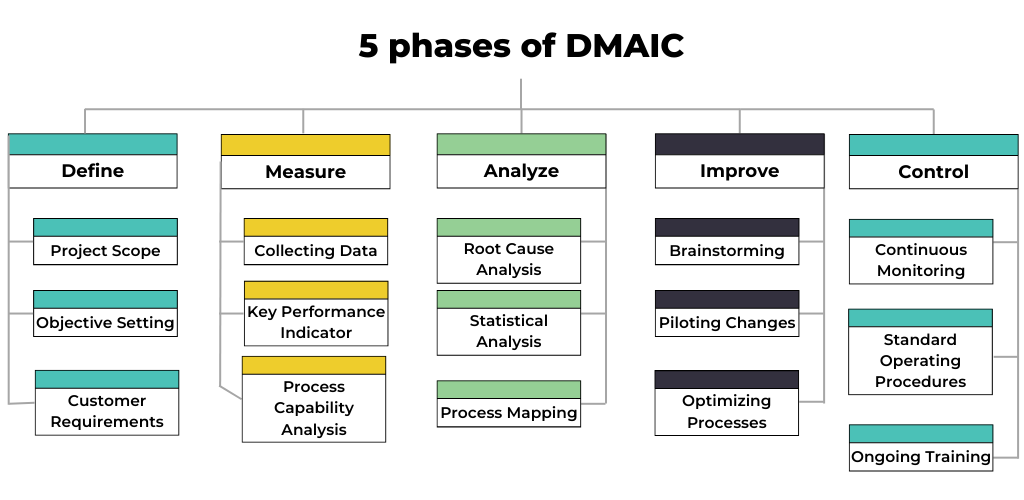

5 phases of DMAIC

1. Define: Making a plan for success

Setting the stage for a good project is like the “Define” phase. It’s about getting everyone on the same page, making goals clear, and really knowing what our customers want. Setting the building plans means that everyone must agree on what to do in order to make something great.

Key Activities:

Project Scope: Making the project’s limits clear so that the work stays on track.

Objective Setting: Objective setting involves actively establishing measurable goals in line with the organization’s overall objectives.

Customer Requirements: In order to understand customer requirements, you need to know what the end users want and need.

Significance:

The “Define” part is very important because it makes sure that everyone knows what the project’s purpose and goals are. It makes sure that everyone is on the same page, which helps organizational goals and attempts to improve fit together better.

Example:

Imagine a biomedical pioneer who wants to make it easier to make important medical products. The “Define” phase lays out the specific devices, sets quality standards, and makes sure that methods are in line with strict regulatory requirements.

2. Measure: Precision in Performance Metrics

It’s all about getting our facts straight in the “Measure” step. We gather information to see how things really work, figure out what needs our attention the most, and assess how well our processes are running. It’s like getting a checkup to make sure everything is okay.

Key Activities:

Collecting Data: Collecting the right data to figure out the average performance.

Key Performance Indicator (KPI) Identification: Picking data that show how well the process is working.

Process Capability Analysis: Checking to see if the process can meet the requirements.

Significance:

This part gives you a realistic picture of how things are now, giving you a starting point for making things better. It’s important to use accurate measurements to find problems that need fixing and to check that changes have had an effect.

Example:

Think about a biomedical company that makes devices to help diabetics keep an eye on their blood sugar. During the “Measure” phase, the company gathers information about how accurate glucose readings are, how long it takes for the device to give results, and how often mistakes happen in different settings. These measurements are very important for making sure the gadget works well and follows the rules set by the authorities.

3. Analyze: Decoding the DNA of Efficiency

The “Analyze” phase involves digging into the data to identify root causes and inefficiencies.

Key Activities:

Root Cause Analysis: Using tools like fishbone graphs and 5 Whys to figure out what’s really going on.

Statistical Analysis: Using statistical methods to find trends and connections in data is what statistical analysis is all about.

Process Mapping: Process mapping means making pictures of how things are done now so that you can see what needs to be changed.

Significance:

By finding out why problems happen in the first place, businesses can come up with specific answers. This step is very important for making smart choices about where to put your improvement efforts.

Example:

Consider a manufacturing plant producing automotive parts. They notice a spike in defects during the assembly process, affecting product quality. In the “Analyze” phase:

Root Cause Analysis: The team identifies potential causes, exploring factors like machine settings, material quality, and operator procedures.

Statistical Analysis: By analyzing defect data, patterns emerge. They discover that defects increase during a specific part of the production cycle.

Process Mapping: Creating a visual map of the assembly process highlights critical points where defects occur, aiding in understanding the flow of operations.

Outcome:

The analysis reveals that variations in machine settings during a particular stage are causing defects. With this insight, adjustments are made to maintain consistent settings, reducing defects and improving overall manufacturing efficiency.

4. Improve: Elevating Quality in Every Step

The magic takes place in the “Improve” step. We think of cool ideas, test them out in small ways, and figure out how to make things better. It’s kind of like redecorating a room: you keep trying new things until it looks and feels just right.

Key Activities:

Brainstorming: Getting people from different departments to work together to come up with new ideas.

Piloting Changes: Trying out suggested changes on a small scale first, before putting them into full effect.

Optimizing Processes: Making processes more efficient and improving how things are done now.

Significance:

In this step, you put your ideas into action. It’s where companies try out different ideas to see what works best and make sure that any changes they make are in line with their general goals.

Example:

In the manufacturing industry, especially when making medical devices, the “Improve” phase adds the automation dance to the assembly process, polishes the quality control rules with a balletic touch, and plans to make employee training programs better.

5. Control: Sustaining Excellence Over Time

It’s all about making sure the good changes we made last in the “Control” part. We keep an eye on things and train everyone all the time to make sure they’re doing things the right way. You want to make sure it stays beautiful and grows, like taking care of a yard.

Key Activities:

Continuous Monitoring: Setting up tools to keep an eye on key metrics and performance over time.

SOPs: Standard Operating Procedures (SOPs) are ways to make sure that processes are followed consistently and that they are written down.

Ongoing Training: Making sure that workers keep learning in order to keep up high standards of performance.

Significance:

To keep the gains going, you have to be careful. During the “Control” phase, steps are taken to keep the organization running at its best and stop it from going backwards.

Example:

For a healthcare company, the “Control” phase includes setting up a strong system for patient feedback, holding regular training symphonies for medical staff, and keeping a close eye on how well established protocols are being followed.

FAQ:

Q1: How does “5 phases of DMAIC” differ from other problem-solving methodologies?

A1: Fundamentally, DMAIC is a process with the purpose of reducing defects and thus improving quality. It has a structured approach and, therefore, follows a specific path. These two are the only unique and distinctive features.

Q2: Can DMAIC be applied to any type of process or industry?

A2: If you check all five steps, it is relevant for all industries. It can address a wide range of challenges and provide solution.

Q3: What role does data play in the DMAIC process?

A3: Data lies at the core of the DMAIC process. Without data, “measure” and “analyze” would be meaningless. Without data, “improvement” would be meaningless because that will not be quantifiable.

Q4: How long does it typically take to complete a DMAIC project?

A4: There is no “one size fits all” answer for this. The bigger the project, the longer the completion time.

Q5: What are some common challenges faced during the DMAIC process?

A5: Challenges will be mainly of two types. 1. Absence of data: without data, it’s difficult to complete all the steps. 2. Resistance from stakeholders: If stakeholders do not engage or take active participation, the process is most likely to fail.

Q6: Can DMAIC be combined with other improvement methodologies, such as lean?

A6: Yes, definitely; in fact, that would be more efficient. Lean Six Sigma is a popular approach but like that, DMAIC can be combined with other approaches too.

Experience an hour of enlightening Six Sigma discussion featuring two industry experts.

Couldn’t catch the webinar live? Kick back and watch the recorded session right here.

Want to access the Six Sigma presentation? Click on the image below!

Conclusion:

We hope this blog was helpful in understanding the 5 phases of DMAIC. In some cases, you might also come across one extra step at the end of the step, “control.” The sixth step is called “verify,” and we do have another article written on that subject too. Do check out “What are the six steps of Six Sigma?“.

If you have any questions, feel free to reach out. We will highly recommend watching the webinar. After watching that, you can download the presentation too; it has a lot of important information.