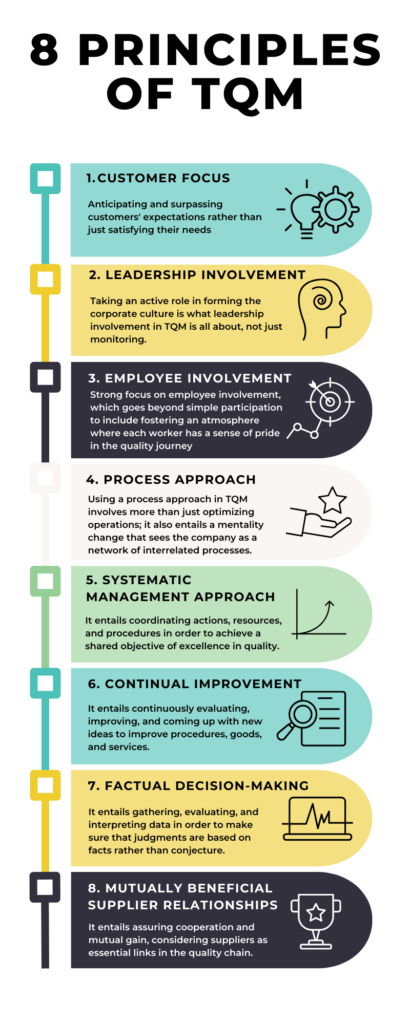

In our blogs, we have been covering various aspects and fundamentals of Total Quality Management (TQM). So today we are going to discuss another fundamental aspect, i.e., the 8 principles of TQM. The 8 principles of TQM are as follows: 1. Customer focus; 2. Leadership involvement; 3. Employee involvement; 4. Process approach; 5. Systematic management approach; 6. Continual improvement; 7. Factual decision-making; and 8. Mutually Beneficial Supplier Relationships.

However, these principles are different from 4 pillars of TQM but in this blog, we will try to answer that question in detail.

Prefer video over text? Check this out!

Let’s jump right in to understand each principle.

1. Customer Focus

Firstly, in TQM, customer focus essentially refers to anticipating and surpassing customers’ expectations rather than just satisfying their needs. Moreover, it’s a continuous conversation that helps products and services naturally fit in with what customers actually want. The key steps to attain customer focus are:

- Customer Research

- Customer Personas

- Effective Communication

- Employee Training

- Personalization

- Quality Products/Services

- Feedback Loops

- Responsive Support

- Measure Customer Satisfaction

- Competitor Analysis

- Continuous Improvement

- Innovate Responsively

E.g.

Apple Inc.’s customer-centric approach is a creative endeavour. Apple creates ecosystems that engage with people on a deeper level than merely products, forging an emotional bond that extends beyond the transaction.

A study published in the Harvard Business Review highlights the financial impact, demonstrating that businesses with a strong customer focus saw increases in income in addition to satisfaction gains.

2. Leadership Involvement

Secondly, taking an active role in forming the corporate culture is what leadership involvement in TQM is all about, not just monitoring. Additionally, leaders offer the essential resources for high-quality initiatives, establish a sense of purpose, and set the standard for accountability. Some key ways in which leadership can be actively involved in TQM are:

- Commitment to TQM Principles

- Provide Resources

- Establish a TQM Culture

- Training and Development

- Empower Employees

- Leadership by Example

- Communication

- Feedback and Recognition

- Continuous Improvement

- Quality Metrics and Measurement

- External Benchmarking

- Customer Focus

- Review and Audit

E.g.

Toyota’s TQM performance, for instance, is evidence of engaging leadership as opposed to dictating. Leaders take an active role in fixing problems and creating a team atmosphere that encourages each worker to make a contribution.

3. Employee Involvement

TQM places a strong focus on employee involvement; moreover, this goes beyond simple participation to include fostering an atmosphere where each worker has a sense of pride in the quality journey. Additionally, it’s important to realize that any level of the organization may contribute to innovation and progress. Here are practical steps to foster greater employee engagement in TQM:

- Create a Culture of Openness

- Leadership Support

- Provide TQM Training

- Define Clear Objectives

- Empower Employees

- Feedback Mechanisms

- Recognition and Rewards

- Cross-Functional Teams

- Continuous Improvement Culture

- Provide Resources

- Communication Channels

- Promote Knowledge Sharing

- Celebrate TQM Milestones

- Set Realistic Goals

E.g.

This idea is best shown by Google’s “20% time” philosophy, which grants staff members the freedom to innovate and promotes an environment where everyone’s opinion counts.

A clear relationship between profitability and great employee engagement can be found in Gallup’s poll, which highlights the financial impact.

4. Process Approach:

Using a process approach in TQM involves more than just optimizing operations; it also entails a mentality change that sees the company as a network of interrelated processes. To get rid of inefficiencies, these processes must be identified, examined, and optimized. Here are the steps to having a sound process approach:

- Identify and Define Processes

- Understand Process Interactions

- Establish Process Owners

- Define Process Objectives

- Document Processes

- Identify Key Performance Indicators (KPIs)

- Implement Controls

- Ensure Resource Allocation

- Training and Competency Development

- Continuous Monitoring

- Identify Improvement Opportunities

- Feedback and Communication

- Implement Changes

- Review and Audit

- Document Lessons Learned

E.g.

TQM’s process approach is a continuous commitment to efficiency rather than a one-time project, as demonstrated by Amazon’s unwavering pursuit of process perfection.

5. Systematic Management Approach

The integrated, organization-wide attitude that TQM advocates for is what makes a systematic approach to management more important than just having processes in place. It entails coordinating actions, resources, and procedures in order to achieve a shared objective of excellence in quality.

- Establish Clear Objectives

- Identify Key Processes

- Define Process Metrics

- Implement Standard Operating Procedures (SOPs)

- Training and Skill Development

- Establish Monitoring and Measurement Systems

- Feedback Mechanisms

- Continuous Improvement Culture

- Data-Driven Decision Making

- Leadership Support and Involvement

- Regular Audits and Assessments

- Adaptability to Change

E.g.

IBM’s success with Six Sigma comes from more than just implementing a technique; it comes from weaving it across the entire company to create an environment where making decisions based on data comes naturally to everyone.

6. Continual Improvement

TQM’s dedication to ongoing improvement is a pervasive organizational culture rather than a one-time project. It entails continuously evaluating, improving, and coming up with new ideas to improve procedures, goods, and services. Here are some strategies to implement continual improvement;

- Kaizen Events

- Failure Mode and Effects Analysis (FMEA)

- Cross-Functional Collaboration

- Voice of the Employee (VoE) Programs

- Technology Adoption

- Incentive Programs for Improvement Ideas

- Visual Management

- Sustainability Initiatives

- Customer Journey Mapping

- Risk Management for Innovation

- Cultural Diversity and Inclusion

- Storytelling for Learning

- Lean Principles

- Trend Analysis

E.g.

Consider Toyota’s Kaizen concept, which exemplifies this idea and shows that TQM isn’t about big, sudden changes but rather steady, small ones.

7. Factual Decision Making

The TQM emphasizes factual decision-making, which goes beyond simply depending on data to include developing a data-driven attitude. Furthermore, it entails gathering, evaluating, and interpreting data in order to make sure that judgments are based on facts rather than conjecture. Here’s how to implement factual decision-making in TQM:

- Define Decision Criteria:

- Data Collection:

- Data Analysis:

- Establish Cause-and-Effect Relationships:

- Use of Pareto Analysis:

- Benchmarking:

- Cross-Functional Collaboration:

- Visual Representation:

- Risk Analysis:

- Decision Matrices:

- Test and Validate Hypotheses:

- Critical Thinking:

- Continuous Monitoring:

- Document the Decision-Making Process:

E.g.

Procter & Gamble’s ability to make well-informed decisions based on market trends and consumer preferences guarantees that product development is not a haphazard endeavour.

A Forbes article demonstrates the financial benefits by showing that businesses that use data to inform their decisions are more successful.

8. Mutually Beneficial Supplier Relationships

Lastly, TQM focuses on building partnerships rather than just transactional interactions when it comes to supplier relationships. Additionally, it entails assuring cooperation and mutual gain, considering suppliers as essential links in the quality chain. Here are some strategies to foster and maintain such relationships:

- Clear Communication:

- Long-Term Partnerships:

- Joint Goal Setting:

- Collaborative Problem-Solving:

- Quality Audits:

- Supplier Training and Development:

- Performance Feedback:

- Incentive Programs:

- Supplier Collaboration Platforms:

- Mutual Trust and Respect:

- Risk Management Together:

- Shared Cost Savings:

- Regular Performance Reviews:

- Continuous Improvement Projects:

- Supplier Development Programs:

- Clear Contracts and Agreements:

E.g.

TQM views suppliers as strategic allies in guaranteeing product availability and prompt delivery, as demonstrated by the cooperation between Walmart and its suppliers.

Frequently Asked Questions

1. How much time does it take an organization to adopt TQM?

TQM is a journey rather than a quick fix, even though the timeline varies. Since the concepts require time to get embedded in the corporate culture, it could take an average of one to three years to observe noticeable changes.

2. Is TQM exclusive to the manufacturing sector?

No, TQM ideas are applicable everywhere. Regardless of the industry, the goal is to improve processes and provide value to clients, whether in the service, healthcare, or educational sectors.

3. What difficulties might organizations have when implementing TQM?

Typical obstacles, such as poor leadership commitment, reluctance to change, and trouble coordinating staff activities with quality objectives, can impede progress. However, understanding that change takes time, overcoming these obstacles calls for a methodical and patient approach.

4. Is TQM different than Six Sigma?

TQM is a comprehensive management philosophy focused on continuous improvement and customer satisfaction, while Six Sigma is a data-driven methodology specifically designed to minimize defects and improve process performance. TQM is holistic and emphasizes employee involvement, whereas Six Sigma employs the DMAIC framework for problem-solving with a strong emphasis on statistical analysis.

Conclusion

TQM is more than just a collection of guidelines; it’s a cultural revolution that leads businesses to become world-class enterprises. Organizations may realize the full potential of TQM by comprehending and embracing the subtleties that go beyond definitions. This is a journey that changes not just procedures but also the core of how they function. While navigating TQM, keep in mind that it’s a continuous journey towards organizational excellence rather than a set route.