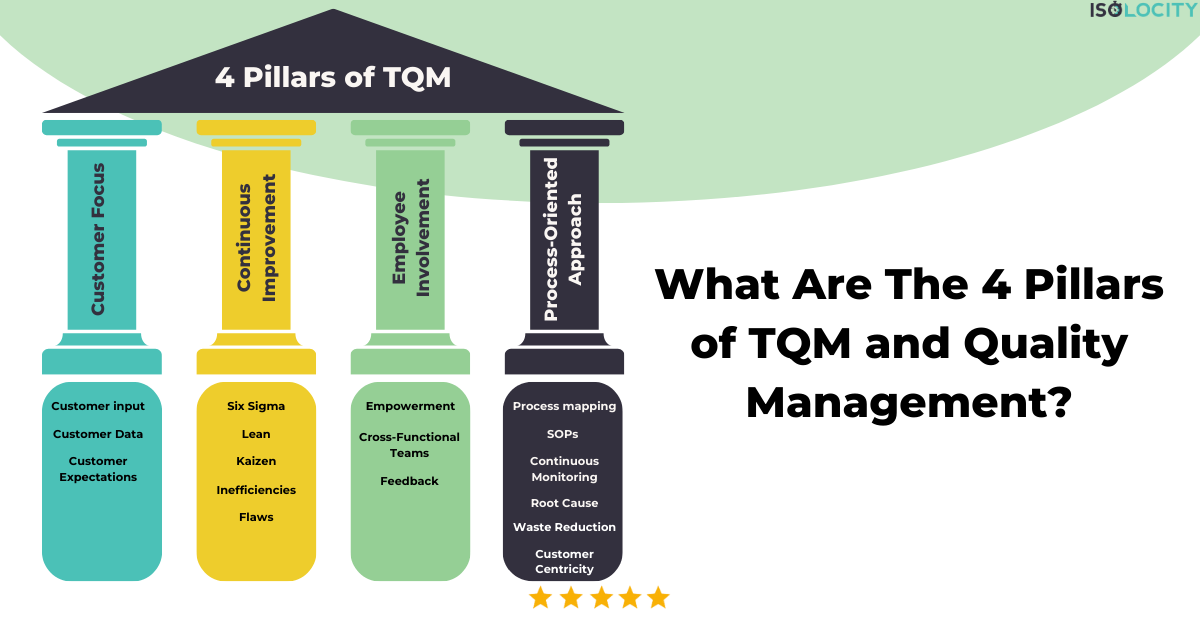

TQM is a specific approach to quality management. It primarily involves a holistic, organization-wide focus on continuous improvement and begins or ends with customer satisfaction. So even if you do everything correctly but the customer doesn’t like the quality of the product, the TQM approach will require revisiting. However, quality management is a broader concept that includes TQM and other methodologies and techniques. So when discussing the foundational pillars of TQM and quality management, they are often perceived as similar, but that’s not the case. TQM, being a very specific approach, is mainly built upon 4 pillars. If you want to break them down further, yes, you can, but fundamentally, they will still be based on those 4 pillars. These 4 pillars of TQM are: customer focus, continuous improvement, employee involvement, and a process-oriented approach.

But when it comes to the broader topic of quality management, they are based on 4 foundational pillars too and they revolve around the topic of quality only. Those 4 pillars are: quality planning, quality control, quality assurance, and quality improvement.

We discussed the 8 principles of TQM in a separate blog post as well; do check that out.

Recent study: Analysis of total quality management (TQM) implementation in the biotechnology industry

Now let’s discuss them in detail.

Need help with your quality management system? Talk to our product specialist.

Video version of the 4 pillars of TQM and Quality Management blog!

What is Total Quality Management (TQM)

TQM is a mindset and way of running a business. It is a subset of quality management as a whole. It actively encompasses an approach that focuses on involving everyone in an organization’s efforts to keep improving. The main goal of TQM is to make sure that all processes, goods, and services are of high quality and stay that way.

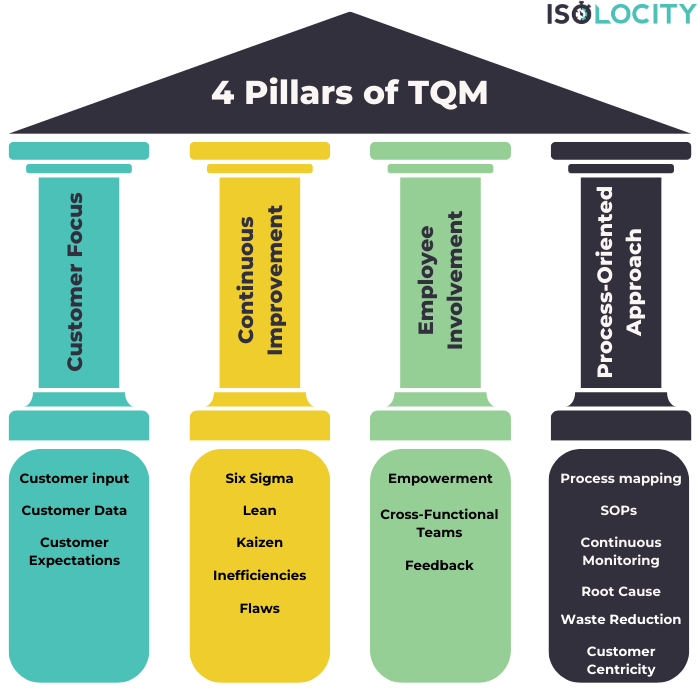

What are the 4 pillars of TQM?

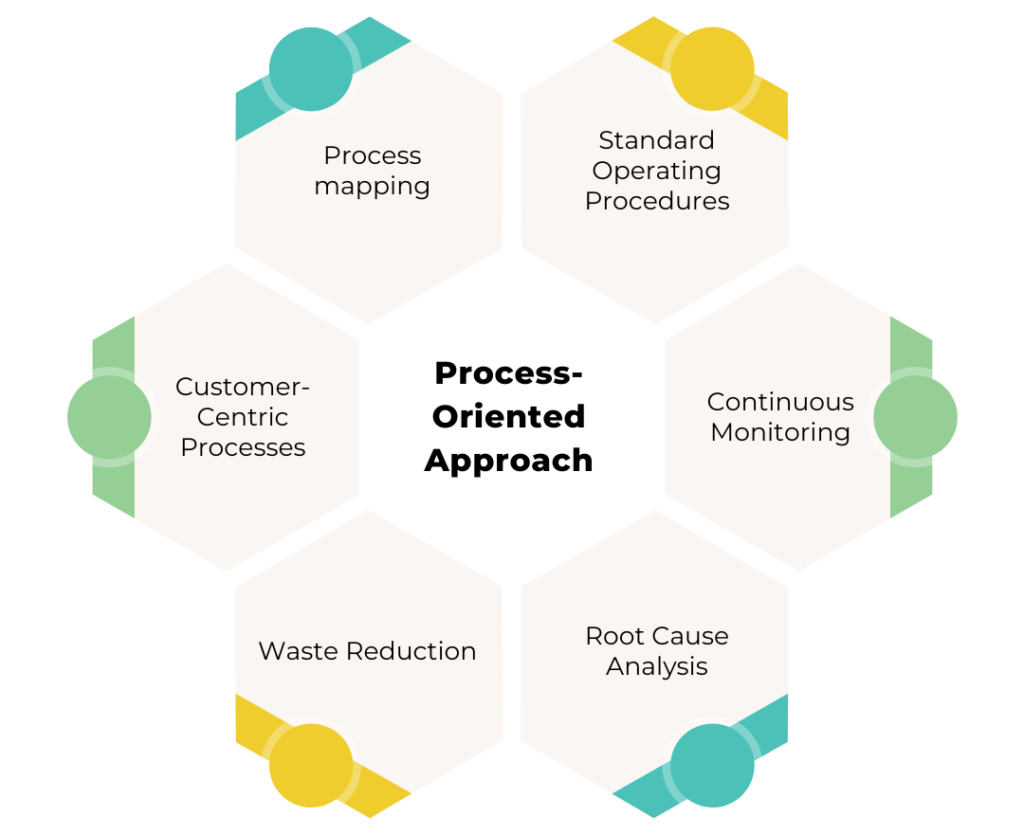

The 4 pillars of TQM—customer focus, continuous improvement, employee involvement, and a process-oriented approach—are the foundation of TQM, which involves meeting customer expectations through lean methodologies and cross-functional collaboration. Each pillar also encompasses sub-pillars, as depicted in the image. Thus, someone might explain them as 8 pillars or 12 pillars, but fundamentally, they all fall into these 4 categories.

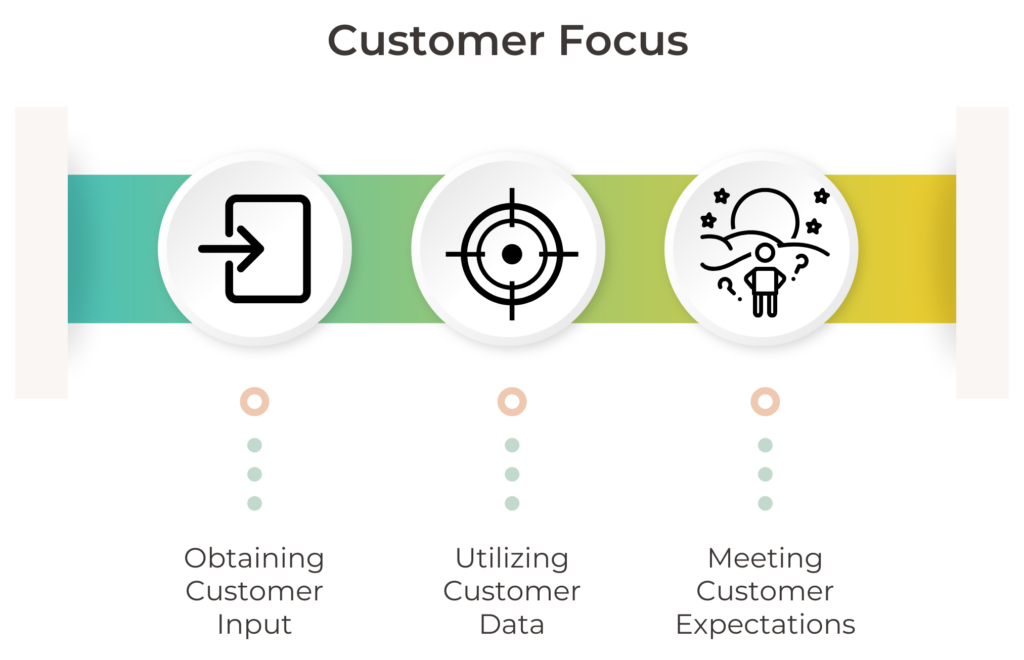

1. Customer Focus:

Obtaining Customer Input: To better understand the requirements, preferences, and pain areas of their customers, businesses actively gather input from them through surveys, suggestion boxes, online reviews, and face-to-face contacts.

Utilizing Customer Data: Businesses actively analyze customer data to learn more about consumer preferences and identify areas for development, such as purchase history and behavior trends.

Meeting Customer Expectations: To increase satisfaction and foster enduring customer loyalty, TQM attempts to align products and services with customer expectations.

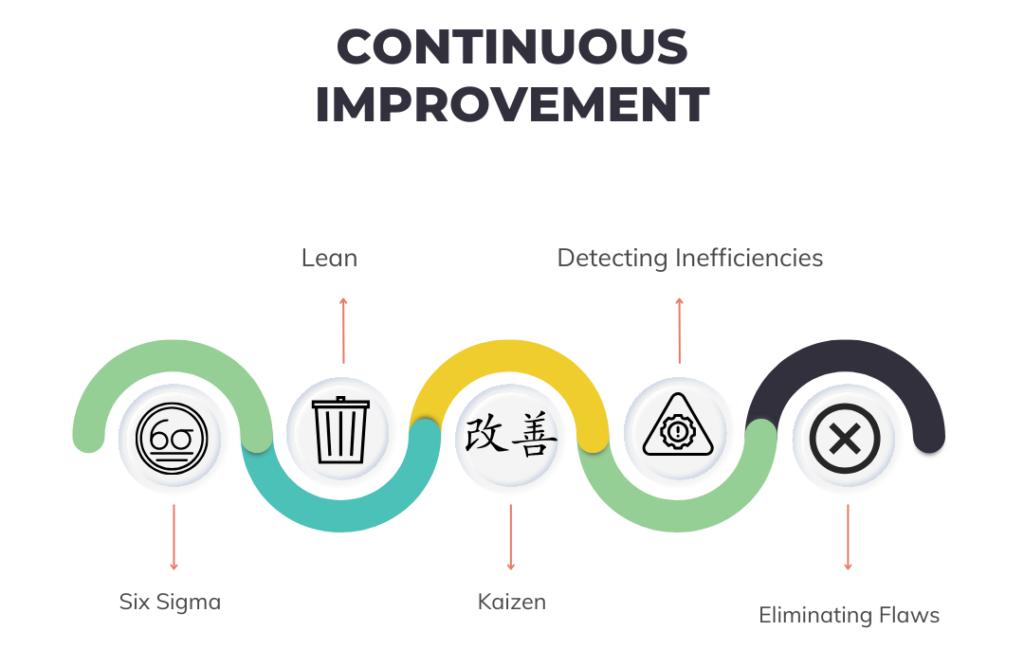

2. Continuous Improvement:

Six Sigma: Using statistical techniques to find and get rid of flaws in procedures, goods, and services. Check out our blog, ” What are the 6 points of Six Sigma?” to understand the concept of Six Sigma better.

Lean: A method for increasing productivity and customer value by focusing on decreasing waste and inefficiencies.

Kaizen: The encouragement of small, gradual improvements by involving workers at all levels to improve effectiveness and quality.

Detecting Inefficiencies: To find areas with bottlenecks or inefficiencies, organizations employ methods like process mapping and root cause analysis.

Eliminating Flaws: Addressing identified problems and coming up with creative answers to improve overall performance is a part of continuous development.

3. Employee Involvement:

Empowerment: The organization fosters a sense of dedication and accountability by giving employees the freedom to decide for themselves and accept responsibility for their job.

Cross-Functional Teams: Establishing teams with a variety of expertise and knowledge facilitates cooperative ideas and issue-solving.

Employee Feedback: Encouraging employees to provide feedback and suggestions for improvement, as they often have valuable insights from their day-to-day experiences.

4. Process-Oriented Approach:

Process mapping: Visualizing processes makes it easier to comprehend how they work and spot areas for improvement.

Standard Operating Procedures (SOPs): Establishing and adhering to standardized procedures actively ensures consistency and minimizes output variance. Here’s a sample of a CAPA SOP that you can download and use.

Continuous Monitoring: Organizations can spot deviations and take remedial action by routinely monitoring process performance using KPIs.

Root Cause Analysis: Finding the sources of issues enables targeted solutions and stops reoccurring problems. Read how organizations can improve efficiency with 3×5 root cause analysis.

Waste Reduction: Putting lean principles into practice makes it easier to spot and get rid of waste, such as pointless tasks, delays, and extra inventory.

Customer-Centric Processes: To produce high-quality goods and services, TQM connects processes with customer requirements and expectations.

Together, these 4 pillars of TQM form a culture of quality in which everyone in the organization is dedicated to customer pleasure and ongoing product development. TQM is a long-term commitment to excellence and customer-focused procedures rather than a one-time effort.

What is Quality Management?

This is a broad term that includes all of the things an organization does to ensure the quality of its goods or services. It means planning, keeping track of, and improving different parts of a business to meet or beat customer standards. Quality management can include the following things:

- Quality assurance: making sure that goods or services meet certain standards.

- Quality control: measuring and keeping an eye on the quality of a product or service.

- Quality improvement: making changes to improve quality.

The 4 pillars of Quality Management

You will find numerous articles on this subject. Some articles would refer to leadership, customer focus, etc. as pillars. But some other articles would argue that activities like “act” or “plan,” etc. are pillars of quality management. Even though we do not disagree with these points, because they are universal truths for any concept and any business (e.g., customer focus is always important for any vertical of a business), we thought we would answer this topic from a quality management point of view.

If we talk about the fundamentals of quality management, there are essentially 4 pillars,

- Quality Planning

- Quality Control

- Quality Assurance

- Quality Improvement

Let’s discuss this in detail.

Related blogs:

Quality Planning

Quality planning is the process of setting quality goals and objectives. It’s a critical part of your overall quality management plan, and it helps you create strategies to meet your goals.

The first step in quality planning is determining your company’s vision, mission, and core values. This should be done as early in the process as possible so that you can use it to guide future decisions (like choosing between two competing products).

The next step would be defining quality objectives. That should start with a business plan, the goal of the company, requirements, and development.

Once you’ve identified these, it’s time to move on to setting quality goals for your organization. It’s important that you quantify the same. Here are a few examples:

- Increasing customer satisfaction by 10% within two years

- Cutting down defects by 50% within three years

Once these goals are set, it’s important for managers across all levels of an organization—from executives down through support staff—to fully understand them so they can be put into practice throughout every department and division within their respective areas of responsibility.

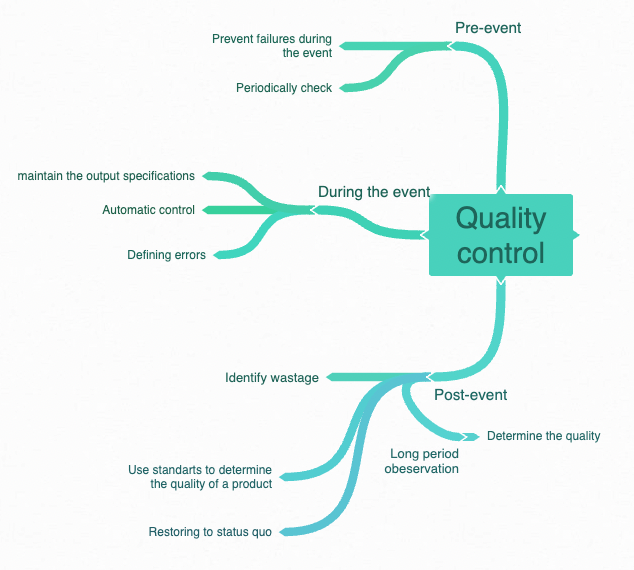

Quality Control

Out of the 4 pillars of quality management, quality control is one of the most important. Quality control is the measurement of quality to ensure that the product or service meets the requirements of the customer. It involves all activities that determine whether or not a product or service conforms to established standards.

Until and unless we have proper control measures, a product cannot meet its quality targets. It is divided into three sections:

-

Pre-event: The quality process would involve certain checks so that any errors can be minimized during or post-event. This involves checking everything periodically.

-

During the event: This process involves maintaining output specifications, and defining and resolving errors so that the developed product is of the desired quality.

-

Post-event: After the event, the process checks for wastage so that it can be minimized in the future, and determines the quality as per the standards by short and long observation.

Once all these processes are complete, it moves on to quality assurance.

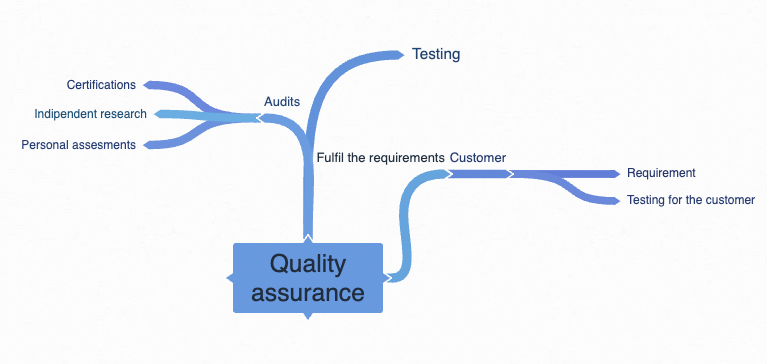

Quality Assurance

Quality assurance is a process to ensure that the product or service meets the customer’s needs and expectations. It involves planning, implementing, and monitoring activities aimed at improving quality. For example:

- The company has contracts with its customers that specify the parameters for acceptable print jobs.

- The company has performance standards for individual employees who work on print jobs.

- The company measures performance based on these parameters and standards to ensure customer satisfaction with its services.

Some of the activities of quality assurance are testing, audits, and understanding if the product is developed as required by the customer. For internal audits, you can hire an iso 9001 consultant.

Special note: People often get confused about the difference between quality assurance and quality control. We have written a detailed blog on this subject, check out the blog, QA vs QC to know more.

Quality Improvement

Quality management is never a one-time activity. It is a continuous process of improvement in the processes and systems that affect quality. The goal of quality improvement is to eliminate the root causes of problems, reduce rework, increase customer satisfaction, and improve employee motivation. Quality improvements can be made in all areas of your business: products, services, and processes.

The quality improvement department actively seeks answers to questions such as why there exists a gap between performance and expectations, how to minimize it, whether we are moving in the right direction, and if not, what we can do differently. Instead of focusing on one single issue, they look at this holistically. The objective is to improve the quality based on available data, opportunities, and records.

The Connection Between Quality Management and TQM

The connection between TQM and quality management is that TQM is a more thorough and organized way to control quality. TQM goes further than quality management by putting an emphasis on four key pillars: customer focus, continuous improvement, employee participation, and a process-oriented approach (also known as the 4 pillars of TQM). TQM is a change in how an organization thinks and acts, with the goal of excellence and continuous improvement in all parts of its processes.

In short, quality management is a broader term that includes many different activities related to quality. TQM, on the other hand, is a specific method of quality management that focuses on a holistic and collaborative way to improve quality. TQM builds on the ideas of quality management but takes them to a higher level by incorporating them into the culture and plan of the organization.

Conclusion

In conclusion, Quality Management and TQM are intertwined concepts focused on ensuring superior products and services. While Quality Management encompasses a broad range of activities such as planning, control, assurance, and improvement, TQM represents a more comprehensive and collaborative approach to achieving excellence.

The 4 pillars of TQM—customer focus, continuous improvement, employee involvement, and a process-oriented approach—lay the groundwork for fostering a customer-centric culture, driving ongoing enhancement, and empowering employees to contribute to organizational success.

In contrast, the 4 pillars of quality management—quality planning, control, assurance, and improvement—complement TQM’s principles, emphasizing the importance of setting goals, measuring performance, and implementing strategies for quality enhancement.

By embracing both Quality Management and TQM principles, organizations can create a culture of continuous improvement, prioritize customer satisfaction, and achieve excellence in every facet of their operations. Ultimately, these integrated approaches pave the way for long-term success, adaptability, and sustained growth in today’s competitive business landscape.

Graph credit: Coggle